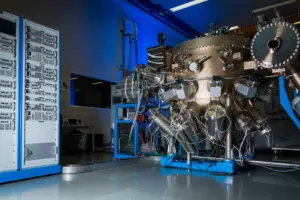

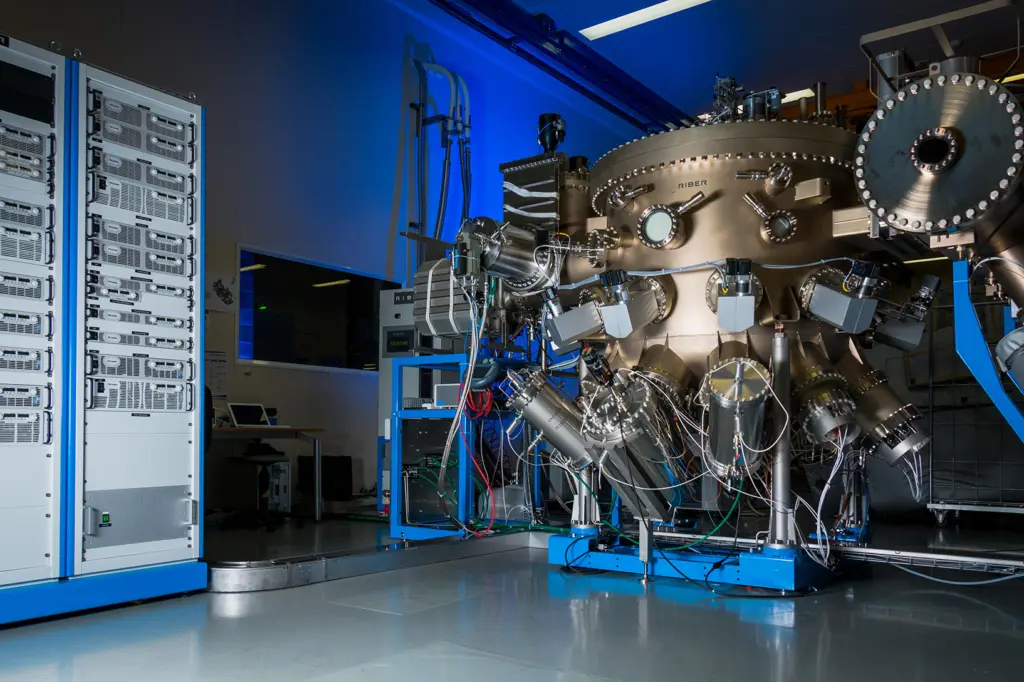

Riber and IntelliEPI, key players in the molecular beam epitaxy (MBE) equipment industry, have recently marked a significant milestone in their joint development of the MBE 8000 platform. The MBE 8000, Riber’s latest production tool, presents the highest capacity available, accommodating batches of either eight 150 mm or four 200 mm wafers.

The machine’s design leverages more than two decades of MBE system experience, with installations in operation worldwide. Its advanced features promise efficient process performance and stability, potentially reducing overall cost for users.

In the testing phase, the MBE 8000 platform has demonstrated excellent uniformity, low defect densities, improved yields, and abrupt interfaces — factors of crucial importance for creating high-performance lasers. The platform’s potential for high repeatability in large-scale production can spur the development of a new generation of lasers, especially in the burgeoning field of vertical-cavity surface-emitting laser (VCSEL ) technology.

VCSEL technology holds immense potential for applications such as under-display facial recognition in smartphones. An anticipated shift in VCSEL wavelength from 940 to 1,380nm would enable integration behind organic light-emitting diode (OLED) displays, which are transparent at this wavelength.

Beyond applications in the VCSEL market, the MBE 8000 platform’s precise control of doping uniformity and process stability could lead to enhanced performance in other microelectronic devices.