Merck has developed a new type of barrier material processed using plasma enhanced – atomic layer deposition (ALD) technology. This material is meant to be ideal for use in flexible OLEDs. To that end, it has been recognized for its outstanding performance, winning the Display Component of The Year 2023 award (through its North American subsidiary, EMD Electronics) from the Society for Information Display (SID).

The introduction of flexible or free-form OLED devices presents a new challenge, as these require a considerable reduction in the display module’s thickness. Of course, we all know how OLEDs are sensitive to degradation by exposure to moisture and oxygen. That is why encapsulation or barrier layers are necessary to protect our beloved delicate OLEDs. These barrier layers need to be flexible and conformable tofree-for devices, but also durable enough to effectively shield the OLEDs.

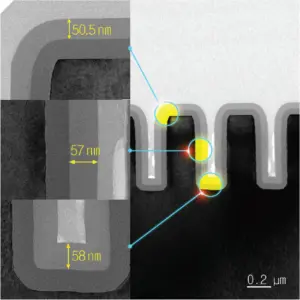

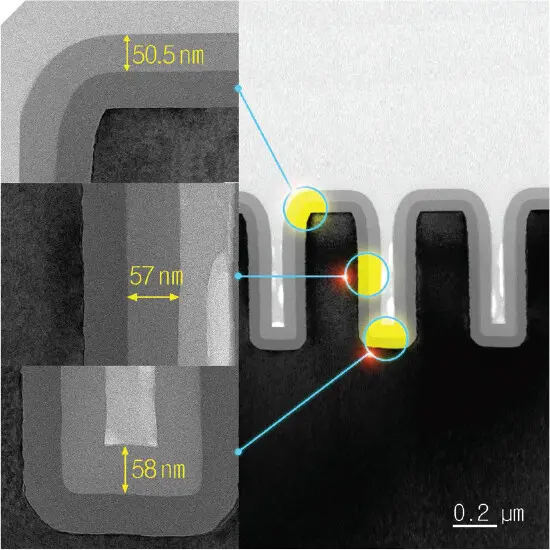

Merck’s barrier materials stand out due to their performance characteristics. Processed via low-temperature plasma enhanced ALD technology, these materials provide an effective barrier that’s 100 times more efficient and 20 times thinner than existing solutions. ALD is a technique used to deposit thin, high-quality films onto a substrate. It’s employed widely in the semiconductor industry. Plasma enhanced ALD involves the use of a plasma, an ionized gas, to facilitate the deposition process at lower temperatures. This is beneficial for materials that are sensitive to heat.

Flexible OLEDs are critical for future applications beyond traditional display screens, such as wearable tech, rollable displays, and biomedical devices. However, the constant bending and stretching of these devices can lead to performance degradation and reduced lifespan. Merck’s new barrier materials mitigate this, protecting the OLEDs while maintaining flexibility.

As a result, Merck is expanding its production of OLED materials, given the growing demand and the new applications enabled by OLED technology. The company recently invested €30 million ($32 million) to expand production in Asia, facilitating quicker access for its Asia-based customers for OLED materials and offering a more flexible supply chain.