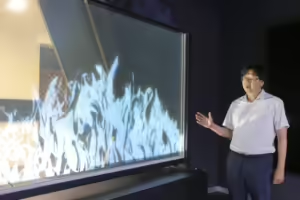

I don’t know how I could have missed this but, earlier this month, scientists at the Korea Institute of Machinery and Materials (KIMM) announced a new approach to creating large, transparent screens at low cost. Their new method resulted in the development of a 100-inch Nano Transparent Screen (NTS), which they claim is not only affordable but also capable of displaying high-definition images with exceptional color and light clarity.

The NTS is made from a film as thin as a human hair, using titanium dioxide (TiO₂) nanoparticles for durability and optical quality. These nanoparticles, evenly dispersed within the film, ensure clear images even when viewed at a wide 170-degree angle. The screen’s transparency can be adjusted according to the environment, providing the most detail when at its most opaque. Additionally, the NTS is highly reflective to targeted light, producing sharp images when illuminated by a powerful projector.

In collaboration with Meta2People, a private company, KIMM has successfully commercialized this innovative screen. The NTS is produced through a roll-to-roll process, where the film is treated with TiO₂ nanoparticles. This process is not only cost-effective but also adaptable to existing manufacturing conditions, allowing the screen to be produced at one-tenth the cost of conventional transparent OLED screens.

The screen’s versatility extends to its application, making it suitable for both indoor and outdoor use due to its resistance to extreme temperatures. It can be integrated into various products such as transparent displays in commercial settings, smart windows for buildings, and promotional displays.

The NTS also incorporates a Polymer Dispersed Liquid Crystal (PDLC) film, which can be made more or less transparent by applying an electrical field. This feature allows users to adjust the screen’s opacity for clearer image projection in different lighting conditions.

Principal Researcher Jun-Ho Jeong emphasized the innovative fusion of nanomaterials and nanomanufacturing technology with existing IT technologies in the creation of the NTS. Moving forward, the KIMM team aims to enhance the quality of NTSs and promote their widespread adoption.