Ink-jet specialist, Kateeva, said that it is planning to double its manufacturing space so that it can meet the demand for its inkjet systems from those wanting to make OLEDs. The move brings the space to nearly 14,000 m² (150,000 sq ft) from 7,000 m² (75,000 sq ft) now at its factory in Newark, California, in Silicon Valley. The company has also tripled its workforce since early 2015 to 330 people. So far, most of the manufacturing has been of its YieldJet thin film encapsulation equipment.

Analyst Comment

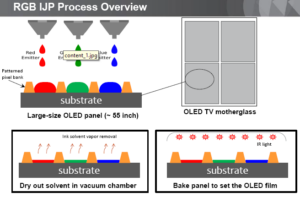

Kateeva said at SID last year that it thought that it could print the OLED materials, as well as providing encapsulation. Since then, LG has said that it is experimenting with inkjet production, which could significantly change the economics of large OLEDs. However, the road to inkjet processing has been a long one. We first reported on the plan to inkjet print OLEDs in 1999, and in 2001, CDT, a pioneer of OLED materials, since bought by Sumitomo, bought Litrex, a specialist in industrial inkjet printers, to accelerate developments. It installed four machines from Litrex for development in 2002. CDT also worked closely with Epson. Sony and Panasonic demonstrated 56″ TV OLEDs made by inkjet printing by Sumitomo in 2009, but didn’t proceed to production. Merck licensed inkjet technology from Epson for its materials in 2012. (BR)