Researchers from the Korea Advanced Institute of Science and Technology (Daejeon, Republic of Korea) or KAIST are developing a white OLED (WOLED) on a thin fiber substrate. Such fibers have the potential for use in applications that included flexible fabric-based displays.

First, a few words of background information.

Up to now, it has been difficult to produce a flexible, full color OLED based on WOLEDs. One reason for this is that conventional “WOLEDs have a tandem structure – a sandwich of electroluminescent units that are stacked atop of each other and separated by charge generation layers. Since the charge generation layer within the tandem structure is thinner than other layers, this layer is particularly vulnerable to bending.” One consequence of this is that the structure and hence WOLEDs are not well suited for use in fibers, fabrics or other flexible materials.

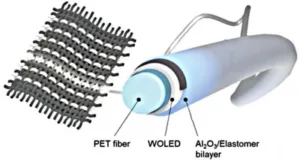

To address the issue of producing a flexible, full color OLED, the researchers investigated an approach that utilized cylindrical fibers with a diameter of 250 µm that were clad with a white light emitting WOLED coating. The WOLED was, in turn, composed of red, green and blue emissive materials that were applied to the fibers by means of a dip coating process. Furthermore, to ensure durability during use as well as to achieve stable operation, the fiber-based WOLEDs were encapsulated with a protective coating composed of an Al2O3/elastomer bilayer.

The figure below is a schematic illustration of a fiber WOLED and its cross-section.

Schematic illustration of a fiber WOLED and its cross-section.

A recent article on this topic by the team is entitled “High-Performance and Reliable White Organic Light-Emitting Fibers for Truly Wearable Textile Displays.” It was published in Adv. Sci. 2022, 9, 2104855. A copy of the article is available on line and can be found here.

The proposed fiber WOLED exhibited high optoelectronic performance and a reliable Color Rendering Index, specifications were comparable to those of a conventional WOLED. (CRI is measured as a number between 0 and 100. At 0, all colors look the same. A CRI of 100 shows the true colors of the object.) Selected performance specifications measured on prototype devices include the following.

The fiber WOLED showed a white CRI value of about 80. Little change was found in the color coordinates (?x = 0.00413 and ?y = 0.00497) between 4 V and 6 V. The fiber WOLED produced a brightness of about 738 cd/m2, a current efficiency value of about 10.8 cd/A and a low operation voltage of less than 6 V.

These specifications add up to the fact that the white OLED fiber demonstrated outdoor visibility and stable white light emission without being affected by the driving environment.

In environmental testing, the device functioned stably after exposure to a saline solution for 300 min without dark spots. In addition, the fiber WOLED operated reliably and exhibited little change after the application of 100 cycles of a load condition of about 1 N. The same was true with the application of 1000 cycles under a tensile strain of 1.5. In general, the researchers claim that the fibers demonstrated resistance to bending, pressure, sweat, water and exhibited biocompatibility.

The researchers conclude their article with the statement that “given that the first fiber WOLED exhibited a comparable level of high optoelectronic performance, reliable color index, and deformability offered by the nature of the fiber, and durability for daily use, we believe that this approach, as a complement to conventional core technology in the field of fiber-based displays, provides building blocks for future research to realize truly wearable displays in the form of a complete platform.” – Arthur Berman

Korea Advanced Institute of Science and Technology, Hwang Yong-ha, [email protected]