One of the most intriguing meetings that we had at CES was in the Westgate Hotel suite with Jasper Display of Taiwan. It was the first time that this reporter has met with the company and it had a lot to talk about – we had more notes after this meeting than any other, so we hope we made good sense of them! We have reported on them several times, especially at SID last year, where it showed displays developed with Glo, and Chris reported after a visit to their Californian facility in 2016 (Jasper Display Shows Working 4K LCOS).

The company is headquartered in Taiwan, but has a big presence in Santa Clara, close to Glo, the nanowire microLED company that it is one of those it is working with. In Taiwan it is working with the Taiwan University on microLED manufacture and transfer.

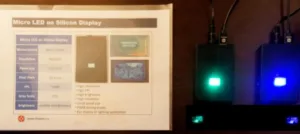

Jasper started with backplanes for LCOS displays, but has exploited its experience to develop backplanes for monolithic microLED displays, which was the main focus at CES. The company has been able to convert from its voltage-driven architecture for LCD to a current source architecture for microLED and the company told us that each pixel is a current source, so it can accurately control the display quality and uniformity at the pixel level.

It has also developed the backplane to be able to handle much higher current than for LCOS. The backplane itself has a lot of metal on the top to cope with currents of two amps. Individual pixels can be from 0.2µA to 1.0µA. This means that it is able to drive brightness up to 100,000 cd/m², although 20,000 cd/m² was the limit on show. The display is a 0.7″ with 8µm pixels giving FullHD resolution.

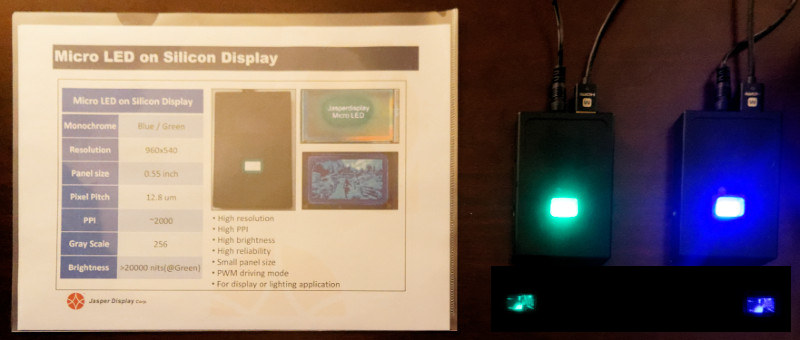

The sample at the show was very bright – getting an image was a challenge. This image is a composite of a regular shot and a very stopped down shot that just captured the images on the displays, but where the background was too dark. Jasper told us that we were the only ones to get a reasonable image at the high brightness! Image:Meko

The sample at the show was very bright – getting an image was a challenge. This image is a composite of a regular shot and a very stopped down shot that just captured the images on the displays, but where the background was too dark. Jasper told us that we were the only ones to get a reasonable image at the high brightness! Image:Meko

In LCOS, Jasper has developed backplanes up to 4096 x 2400 and it has adopted a square, four sub-pixel architecture. This means that the backplane can be used for colour or for monochrome and also means that LED companies have more flexibility to boost the area of one colour or add an additional sub-pixel. That, in turn, means a range of different strategies can be adopted, including mixtures of direct colour emission or colour conversion. If one colour is significantly less bright than the other two, it can use the spare subpixel. The architecture is also very suitable for more sophisticated driving arrangements based on sub-pixel rendering.

It had sent backplanes to have microLEDs added for the higher brightness for the use at the show, but the LED company struggled to get a good sample prepared for the show because of issues with the transfer process. However, the company is very confident that it has solved the challenges of the higher brightness. One of the advantages of its technology is that it typically uses a frame sequential mode for colour, so the amount of time that an individual subpixel is lit is just 10% of the frame time, so overheating can be controlled. To achieve this, the backplane has to be very fast as PWM is used for intensity control. The use of PWM means that (like DLP, we thought to ourselves), the signal chain is 100% digital.

The company told us that the level of control of current, pixel configuration and driving means that the designer can select the gamut without needing to worry about white point, which can be selected independent of the gamut. It also means that the white point can be under control at all brightnesses.

We asked whether the backplanes need special manufacturing facilities, but Jasper told us that ‘any fab’ can make the chips. To facilitate production, Jasper has developed tests for dies and wafers.

The microLEDs that can be used can be down to ‘single digit µm’ sizes and the company says that it can get down to 2µm – which is probably a limit anyway because of optical issues.

In driving, the company has been able to move now from FPGAs to ASICs and these have been redesigned to work with current sources. The firm has also put the frame buffer on the chip which helps reduce the power consumption significantly and makes design simpler. It has a very wide data bus, at 64 bits (or 128 bits for the 4K LCOS chip). It can deal with multiple planes/frame.

Jasper’s LCOS SLMs are large. Image:Meko

Jasper’s LCOS SLMs are large. Image:Meko

The company told us that it sees a wide range of different applications as the design has been made as flexible as possible. The resolution starts at two megapixels. That is in monochrome, so with square pixel arrangements in a 2 x 2 array, that becomes a 960 x 540 resolution, initially.

The design can be optimised for highest brightness for a power budget, or for minimum power and there is no reason why devices should not be qualified for automotive applications or in automotive. As quite a number of the challenges in microdisplay use are in optics and ensuring that small devices have very high visual performance. Here, the company’s experience in projection is very valuable.

The company reminded us that one of the challenges in developing LCOS has been that the image is enormously magnified in a projection application, so QA and QC are both very tricky because of the extreme sensitivity of the human eye to defects and non-uniformities.

In terms of mass production, Jasper is hopeful that real final display products can be shipped in 2019.

Beyond displays, Jasper has a business in LCOS-based SLMs for optical benches and the company sees a lot of applications as the interest develops in lightfield approaches.