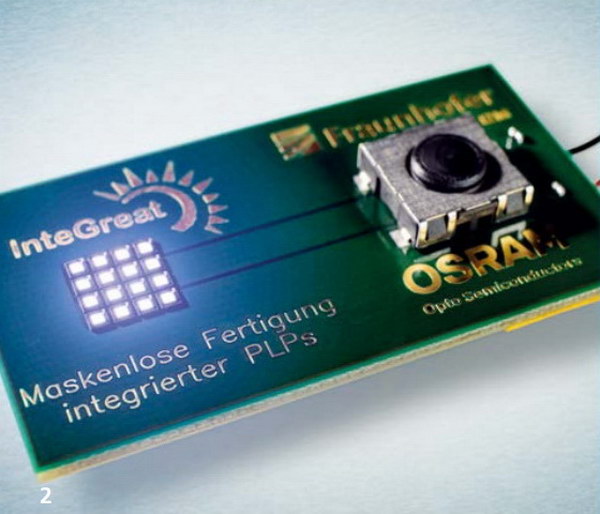

In the InteGreat research project, funded by the German Federal Ministry of Education and Research (BMBF), Osram Opto Semiconductors coordinated a research consortium comprising seven partners from science and industry. Between December 2014 and February 2018 the project partners investigated the normal LED manufacturing approaches and know-how along the entire LED production process. The aim of the project was to identify potential areas for manufacturing optimization from epitaxial wafers through the final packaging and application.

Currently there are many individual steps in the production chain and each individual step tends to be optimized on its own. The InteGreat project, which is part of the “Photonic Process Chains” initiative, was created to optimize the overall epi-to-application manufacturing process as a whole. The results from the project are said to allow LED products to be given additional superior properties that would have been difficult or even impossible to achieve with the technologies previously used to produce LEDs.

Osram Opto Semiconductors partners included Osram, the Fraunhofer IISB (Institute for Integrated Systems and Device Technology), the Fraunhofer IZM (Institute for Reliability and Microintegration), Würth Elektronik (electronic components, PCBs and intelligent power and control systems), LayTec AG (integrated metrology for advanced processes) and Mühlbauer GmbH & Co KG (production equipment). The consortium investigated new approaches for manufacturing very small surface emitting LED chips and packaging technologies, among other things.

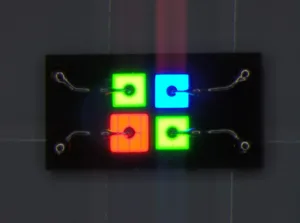

As part of the “Photonics Process Chains” initiative, new approaches for manufacturing very small surface emitting LED chips and packaging technologies were tested, among other things. (Source: Osram OS)

As part of the “Photonics Process Chains” initiative, new approaches for manufacturing very small surface emitting LED chips and packaging technologies were tested, among other things. (Source: Osram OS)

The project also focused on investigations into new connection technologies. One of the pioneering approaches that has emerged from this is planar interconnect technology, which offers numerous advantages – for example for video wall applications.

The project also focused on investigations into new connection technologies. One of the pioneering approaches that has emerged from this is planar interconnect technology, which offers numerous advantages – for example for video wall applications. (Source: Osram OS)

At the heart of the project was wafer level packaging as well as investigations into planar contacts. One of the pioneering approaches to emerge from the project is planar interconnect technology in which the bond wire is replaced by a thin flat metal connection. This moves the surface emitter to the surface of the package. The light can therefore be used more directly, unlike with conventional components. This leads to smaller losses in efficiency and luminance and consequently to greater brilliance and cost savings in operation. Other new technologies along the entire value-added chain for functional full-color video wall modules with a pixel pitch of 1 mm were successfully demonstrated.

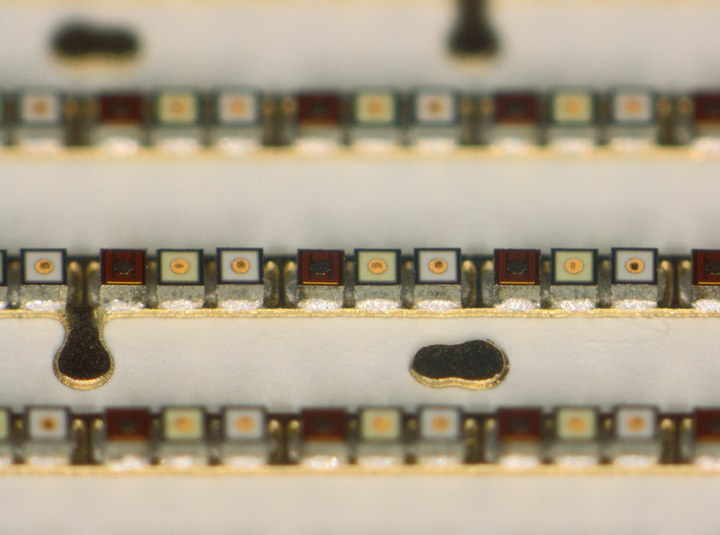

Highly integrated LED-packages manufactured on panel-level as part of the BMBF project InteGreat (Source: Fraunhofer IZM)

Highly integrated LED-packages manufactured on panel-level as part of the BMBF project InteGreat (Source: Fraunhofer IZM)

The results of the project can be applied not only to large-format video walls but also to new applications such as in ambient lighting and sensor systems. The modular structure of the project, which was comprised of four work packages, allows many results to be quickly transferred to product development and production. The integration of LEDs in industrial applications and also in areas such as the mobility of the future can therefore be accelerated. The results also open up huge potential in infotainment, the group believes.

“The results of the InteGreat research project represent a major advance for the future of LEDs. Our powerful consortium of partners from science and industry has delivered extraordinary achievements in three years. Once again we have been able to demonstrate the powers of innovation in Germany as a center of scientific know-how”, said Frank Singer, Predevelopment Group Leader at Osram Opto Semiconductors.

Analyst Comment

We got in touch with Osram Opto Semiconductors Head of External and Internal Communications, Marion Reichl. She said “Unfortunately we cannot provide any additional information currently. The project was finalized and the feasibility shown – now it’s time to check for possibilities to transfer this to mass production.” -Matthew Brennesholtz