Researchers at the KAIST research institute and Pohang University of Science and Technology (POSTECH) in Korea have built a graphene electrode structure, which can be used for ‘highly efficient’ flexible OLED units.

The graphene was used transparent electrode in the new OLED. It was placed in between titanium dioxide (TiO2) and conducting polymer layers. The choice of which electrode to make transparent in an OLED helps to define whether it is bottom- or top-emitting. Bottom-emitting OLEDs emit light through the transparent electrode and substrate on which the OLED was manufactured. Top-emitting units emit through the ‘lid’ that is added during fabrication.

Conventional bottom-emitting OLEDs emit light through the transparent anode (which releases holes into the OLED stack when voltage is applied). ITO is commonly used in the anode. However, this has problems such as being brittle and expensive. The researchers used graphene as a replacement for ITO, with some modification to raise efficiency.

A new device architecture was used. A transparent anode was fabricated in a composite structure, in which a TiO2 layer with a high refractive index (high-n) and a hole-injection layer (HIL) of conducting polymers, with a low refractive index (low-n), sandwich graphene electrodes between them. The design enhances the interplay of the high-n and low-n layers to increase the effective reflective of transparent electrodes. The effect is an improvement in the optical cavity resonance (related to efficiency and colour gamut in OLEDs). In addition, the loss from surface plasmon polariton (SPP) (a significant cause of weak photon emissions in OLEDs) is also reduced, due to the presence of the low-n conducting polymers.

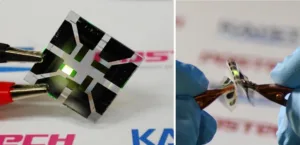

This approach led to an external quantum efficiency of 40.8%, and efficiency of 160.3 lm/W. The researchers say that such figures are ‘unprecedented’ when using graphene as a transparent electrode. The devices also remain intact and operational after 1,000 bending cycles, at a radius of 2.3mm. The use of oxides, such as TiO2, would typically limit this, as oxides are brittle. However, the team found that TiO2 has a ‘crack-deflection’ toughening mechanism, which tends to prevent bend-induced cracks from forming easily.

It is expected that the work can be used in the development of a flexible and/or wearable OLED light source.

The research was published in the journal Nature: http://tinyurl.com/zhqdz25.