The Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology (Fraunhofer FEP) in Dresden has introduced a new OLED microdisplay specifically targeting virtual reality (VR) applications. This is part of the European LOMID project (Large cost-effective OLED microdisplays and their applications).

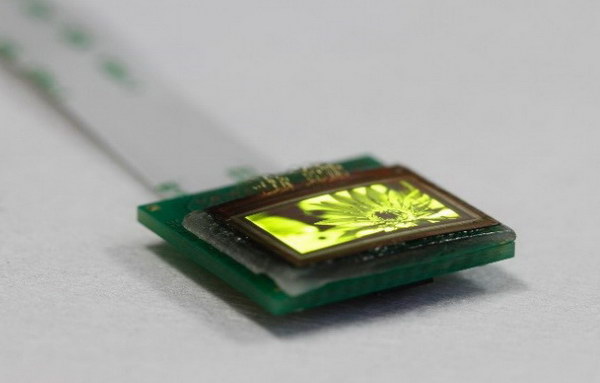

1” WUXGA OLED Microdisplay from Fraunhofer FEP and the European LOMID project. (Credit: Fraunhofer FEP)

The new microdisplay has WUXGA (1920 x 1200) resolution and is on a 1” (25.4mm) diagonal silicon backplane, giving about 2264 pixels per inch. Fraunhofer FEP’s involvement in the project includes designing the silicon backplane and project leadership. The backplane supports 120Hz frame rate which is said to make “movements in the virtual world seem very fluid indeed.” The OLED microdisplay has a contrast of >10,000:1. The microdisplay backplane is based on a low-cost, 0.35 μm CMOS lithography process. By thinning the substrate, the LOMID project has shown that these microdisplays can be bent with a radius of about 40mm. Not only does thinning the substrate reduce the weight, but, more importantly, the curved microdisplay allows simpler, lighter weight and higher resolution optical designs, especially in wide field of view (FOV) applications such as VR.

OLED microdisplay bent to a radius of 40mm.. (Credit: LOMID Project)

OLED microdisplay bent to a radius of 40mm.. (Credit: LOMID Project)

This microdisplay is not only targeted at VR applications, but also at applications that will help the vision impaired, especially those who suffer from macular degeneration, an age-related condition in which sufferers have only peripheral vision.

Fraunhofer FEP is demonstrating the first prototype of this OLED microdisplay at the LOMID booth at the European Forum for Electronic Components and Systems (EFECS 2017) going on at the time of writing (Dec. 5 – 7) in Brussels. In addition, LOMID is demonstrating optical components designed to support the microdisplay. This first prototype contains a color filter array and un-patterned OLEDs. While this device is bright enough for VR applications, Fraunhofer FEP concedes that much higher brightness devices will be required for augmented reality (AR) systems. The best way to achieve this higher brightness in an OLED microdisplay is to use patterned OLEDs.

Is WUXGA Enough?

I asked Dr Uwe Vogel of the Fraunhofer FEP and leader of the LOMID project if he felt the WUXGA resolution of the microdisplay was really sufficient for a wide FOV VR system. For example, in a system with a 100° horizontal FOV and a 62° vertical FOV, this works out to 19.2pixels/degree (PPD) or about 3.1 arc-minutes/pixel. The limit of human visual resolution is commonly taken to be 1 arc-minute, so these pixels would be visible to a VR viewer with normal vision, leading to a screen door effect. Peripheral vision, which would be used for a macular degeneration application, has a much lower resolution and this would be sufficient.

Dr. Vogel said that fill factor strongly affects the perception of the screen door effect. “That’s a regular drawback of today’s smartphone panels used in most VR devices, that easily exhibit <30% fill-factor. That’s partly due to Samsung Displays FMM OLED patterning approach, that limits fill-factor significantly. Thus, alternative approaches for high-res OLED patterning will be needed, e.g., the ebeam-based approach FEP is working on, or photolithography [as used by eMagin], or similar. I may add such high-res patterning approaches should be feasible for up-scaling to larger substrates.”

While Fraunhofer FEP is not currently working on a large backplane design with a higher pixel count, Dr. Vogel says that may be possible, given that 8”/200mm CMOS silicon wafers are currently being used to fabricate the backplane and it may be possible to use 300mm wafers in the future. He is concerned about yield, however, if the backplane goes beyond 1”. I’d also be concerned about cost – a 1” silicon substrate is expensive enough and I wonder if the VR business model could support the cost of a still larger substrate.

Dr Vogel believes that “The combination of the new microdisplays and optical design will result in a huge leap forward in the comfort and acceptance of VR goggles. The application of the displays in visual prosthetics is also very exciting, and could improve the quality of life for millions of people in Europe and around the world.”

The LOMID project started in 2015 and continues through June 2018. The project team is now testing these OLED microdisplays and is using them to build several demonstration systems for VR and visual prosthetics. The demonstrators are expected to be available to potential customers from Q1/2018. -Matthew Brennesholtz