The European Flex-o-Fab project (Flex-o-Fab Demonstrates Flexible OLED from Roll to Roll Process), run by the Holst Centre, has completed its goals in the area of flexible OLEDs.

Launched in January 2013, the €11 million project aimed to realise the technologies needed to commercialise flexible OLEDs. It was run by the Holst Centre.

Some of the project’s key achievements are the development of an indium-free transparent conductive oxide (TCO), and a brighter flexible OLED.

The École Polytechnique Fédérale de Lausanne (EPFL) developed the indium-free TCO, using zinc-tin oxide (ZTO): a common TCO with the same mechanical and chemical stability as ITO, but with relatively poor electrical properties. The EPFT overcame this by improving ZTO’s conductivity and choosing a metal grid to support it.

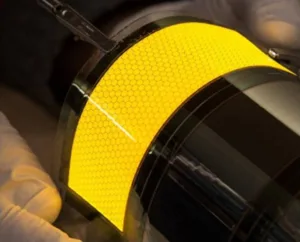

DuPont Teijin Films developed a new ITO-free substrate that raised flexible OLED brightness by about 30%, using plastic with outcoupling features. The substrate was produced using a sheet-to-sheet process and achieved a brightness of 10,000 cd/m² with a white flexible OLED. The process is compatible with roll-to-roll production.