eMagin has been awarded a new patent by the U.S. Patent and Trademark Office (USPTO) for its Direct Patterning Display (dPd) technology. This patent follows two USPTO patents awarded last year and adds to eMagin’s portfolio of 18 foundational dPd patents and utility applications for OLED patterning, processes and equipment.daily

The company has a roadmap for full-color displays targeting a brightness level in excess of 28,000 cd/m² (nits) by mid-2023, with an intermediate brightness of 10,000 nits later this year. There has been a race to develop high brightness displays for Augmented Reality (AR) and Virtual Reality (VR) in recent years.

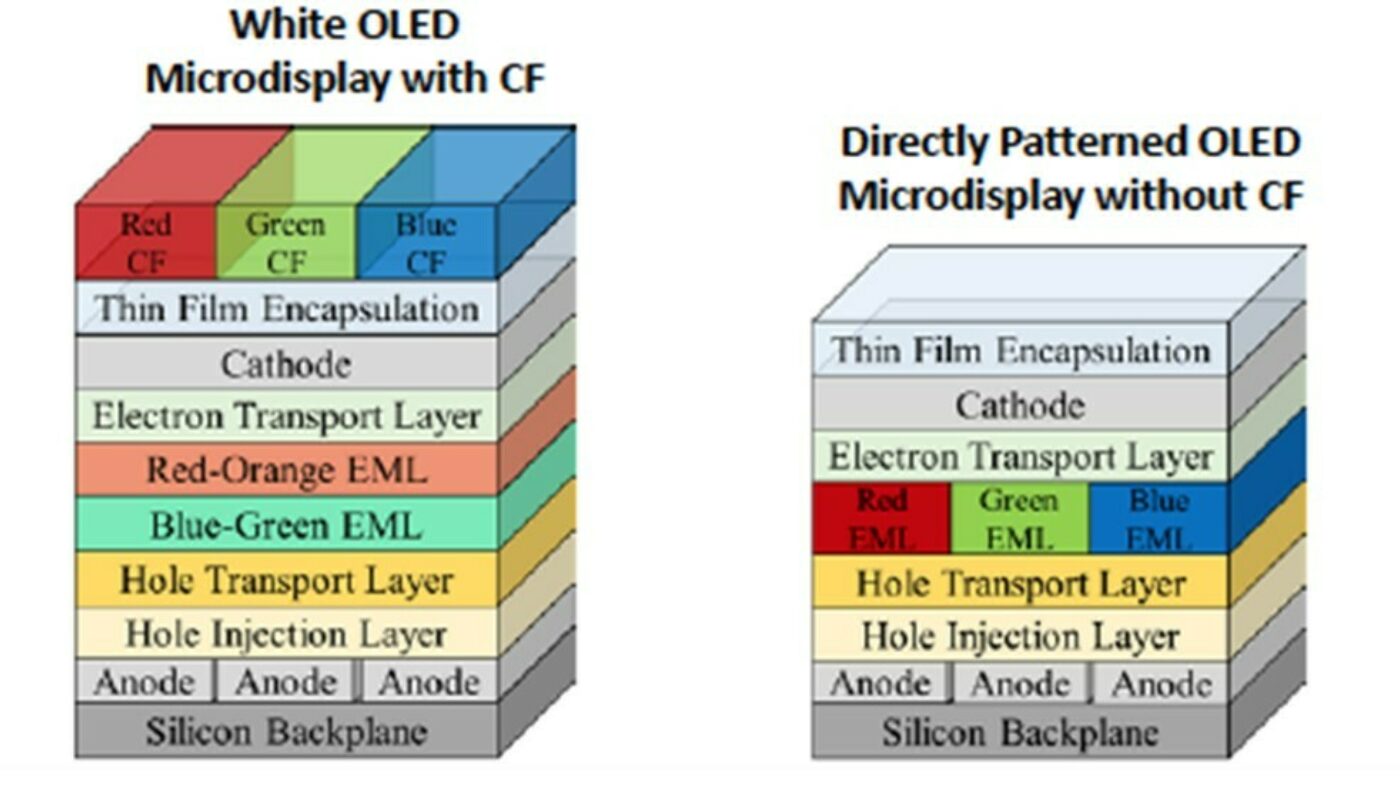

“Our newest patent adds to our technological leadership in brilliant, full-color OLED displays for AR/VR,” said Andrew Sculley, CEO of eMagin Corporation. “Display brightness is critical for both AR and VR devices and for Heads Up Displays (HUDs) used in bright, daylight environments. Our proprietary dPd technology greatly enhances light output relative to competing products that require color filters with white OLED, which reduces the light output by approximately 80 percent.”

OLED microdisplays are usually based on white OLED with a color filter array, but this approach reduces the brightness. Direct patterning of primary RGB OLED emitters can, in theory, enable a much higher brightness as it removes the color filter array. However, the shadow mask technology developed for mobile OLED displays does not provide the level of resolution needed for AR and VR applications. eMagin’s dPd technology enables shadow mask patterning at ultra-high resolutions.

“In terms of brightness, our dPd technology is ahead today and we expect to stay ahead,” said Sculley.

“Combining our roadmap for high brightness and the government funding we secured for equipment, we expect to enhance our technological edge and manufacturing capabilities to support our AR/VR customer needs.”

eMagin OLED structure – Click for higher resolution

eMagin OLED structure – Click for higher resolution

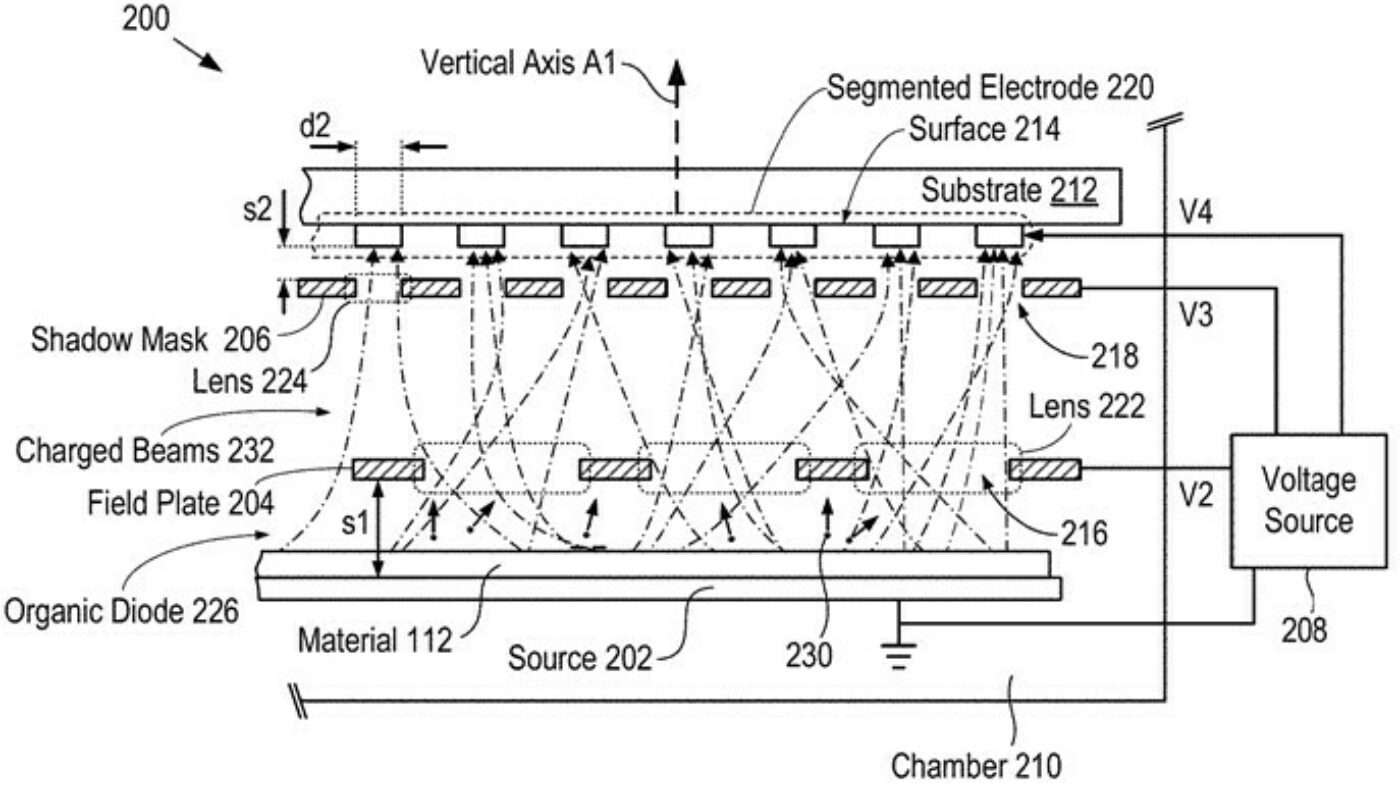

The awarded patent, number 10,903,427, relates to the apparatus and method for direct patterning of an organic material using an electrostatic mask. The patent explains that some molecules can continue to travel laterally after passing through a shadow mask such that the resultant patterned regions extend beyond the edges of the apertures. This lateral spreading, commonly referred to as “feathering”, can be minimized by adding passive collimator structures, but this in turn leads to more material waste and longer process times.

The invention mitigates feathering by imparting an electrostatic force on the molecules traveling from the evaporation source to the target substrate. In one embodiment, the shadow mask is held at a specific voltage and functions as a fine electrostatic mask made of small electrostatic lenses. A field plate placed close to the evaporation source acts as another set of electrostatic lenses. As the vapor molecules approach the field plate, their propagation paths are curved by the electrostatic lenses of the field plate openings. The apertures of the shadow mask function as a finer set of electrostatic lenses, that further refine the propagation directions for the charged vapor molecules. As a result, the vapor molecules exhibit little or no lateral spread as they deposit on the substrate after passing through the apertures of the shadow mask.

Andrew Sculley told DSCC that eMagin is currently talking to three large companies in the consumer AR/VR space. These companies have developed their own optics but are looking for high brightness displays to deliver the best experience. The 10,000 nit display currently in development is for one of these Tier 1 customers.

Sculley stated that VR requires high brightness displays because the optical losses in a headset result in about 10% efficiency. Moreover, a 10% or lower duty cycle is necessary to remove motion blur during fast head movement. To deliver 100 nits to the eye, the display must reach at least 10,000 nits.

For see-through AR, the brightness should be even higher since the display has to match the level of ambient light. To reach 28,000 nits, eMagin can incorporate some of the improvements that are being developed for white OLED with color filters. These include architecture change (e.g., microcavities), new materials and the addition of microlenses.

In 2019, eMagin demonstrated a 4K × 4K OLED display to a consumer electronics company. The display was over 2” in diagonal, an unusually large size for a microdisplay but often necessary for VR applications.

eMagin has received approximately $39 million in recent government awards. Half of this money will be spent to install a larger tool for direct patterning in the company’s US facility. While this tool will enable the initial ramp up in production, the company’s strategy is to license the technology to other fabs in Asia with the capability to reach millions of units per month.

Andrew Sculley will be speaking at the SID/DSCC 2021 Virtual Business Conference on May 17, 2021. There will be a session dedicated to AR and VR, discussing the progress of OLED and MicroLED technologies, and the market size for each application. The SID/DSCC Business Conference is the display industry’s largest and longest running business conference with participation from industry executives and leading financial and market analysts from across the globe. Registration is now open, and sponsorship is still available. (GC)

This article was originally published on the DSCC blog and is reproduced here with kind permission.

Dr. Guillaume Chansin is Director of Display Research at Display Supply Chain Consultants (DSCC). [email protected]

Guillaume was previously Senior Product Line Manager at Plessey Semiconductors where he managed customer projects integrating microLED displays into AR/VR headsets. He led market research activities to position Plessey’s new product lines and understand the competitive landscape. In this role he worked closely with the Business Development and Marketing teams to promote the benefits of monolithic GaN-on-Si for microdisplays.