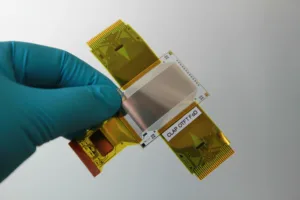

At CES 2023, CLAP showcased OTFT applications of OLED Mobile large-screen fingerprint and transparent Micro LED.

After acquiring OTFT material patents and technologies from Germany’s BASF, CLAP has its own organic semiconductor research fab and is actively developing application products.

OTFT has the advantage of manufacturing devices inexpensively with various coating processes (solution materials) without expensive deposition equipment, and it is possible to manufacture devices on plastic films in a low-temperature process (below 120℃). As a driving substrate for Flexible Electronics that requires flexible functions, the possibility of using OTFT is very high. OTFT can be solutions for IoT infrastructure providing various form factors such as bendable, rollable, and wearable.

In particular, the OTFT manufacturing process is eco-friendly. In the process, if the organic semiconductor and insulator contain the photoreactive material (CLAP’s Crosslinker : XL-100), direct patterning of the TFT becomes possible. The process can be reduced to 1/3 of the existing method using photoresist and reactive ion etching (RIE), hence obtaining an eco-friendly effect such as low carbon emission. This is one of the differentiated solutions of CLAP OTFT.

Organic thin film field-effect transistors (OTFTs) are particularly interesting as their fabrication processes are much less complex compared with conventional Si technology, which involves high-temperature and high-vacuum deposition processes and sophisticated photolithographic patterning methods. In general, low-temperature deposition and solution processing can replace the more complicated processes involved in conventional Si technology. In addition, the mechanical flexibility of organic materials makes them naturally compatible with plastic substrates for lightweight and foldable products. Since the report of the first organic field-effect transistor in 1986, there has been great progress in both the materials’ performance and development of new fabrication techniques. OTFTs have already been demonstrated in applications such as electronic paper sensors and memory devices including radio frequency identification cards (RFIDs). Although OTFTs are not meant to replace conventional inorganic TFTs – because of the upper limit of their switching speed – they have great potential for a wide variety of applications, especially for new products that rely on their unique characteristics, such as electronic newspapers, inexpensive smart tags for inventory control, and large-area flexible displays.

ScienceDirect

Sungho Kim, CEO of CLAP, said, “We are prioritizing commercialization of OTFT for large-screen fingerprint recognition sensors and transparent flexible Micro LED Displays. It will further promote technology through participation in CES 2023 exhibition and expand cooperative partnerships with global companies. Ultimately, CLAP wants to continue as an eco-friendly company that uses less energy, less waste, and less harmful substances based on organic semiconductor materials, and wants to become the world’s best company in Flexible Electronics applications.”