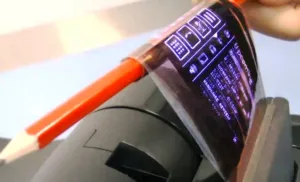

FlexEnable’s OLED display reaches a 60Hz refresh rate and has a 0.25mm bend radiusFlexEnable, the new Cambridge-based company spun off of Plastic Logic (Plastic Logic Divides into Two Companies), claims that its work will enable flexible display production by the end of 2015.

FlexEnable’s technology enables the printing of plastic electronic circuits onto flexible films, as thin as 25µm, in volume. It is a low-temperature technique, not exceeding 100°, which can be applied to existing display panel lines – including for large displays. The resulting circuits would support the high level of current required to enable OLED displays.

Chairman (and Meko friend) Indro Mukerjee says that the company is talking to material firms and Asian display makers about implementing its technology and bringing displays to market.

The process is based on printable transistor technology developed by Plastic Logic for electrophoretic displays. FlexEnable claims to have solved the issue of air and water ingress to the displays, as well. The IP will be licensed to display and sensor manufacturers, and small-order flexible circuit manufacturing will be carried out in Cambridge.

Paul Cain, strategy director at the company, said that the new process has been applied to the production of graphene transistors. A display with a graphene electrode has been created at FlexEnable’s R&D lab in Cambridge.

The first partnerships are expected to be announced within a few weeks.