While QLEDs have shown significant progress in laboratory settings using spin-coating methods, the scalability and cost-effectiveness of inkjet-printed QLEDs remain challenging. The key issue in inkjet-printed QLED fabrication has been the difficulty in achieving highly ordered and uniform QD thin films, leading to lower efficiency and shorter operational lifetimes compared to spin-coated QLEDs.

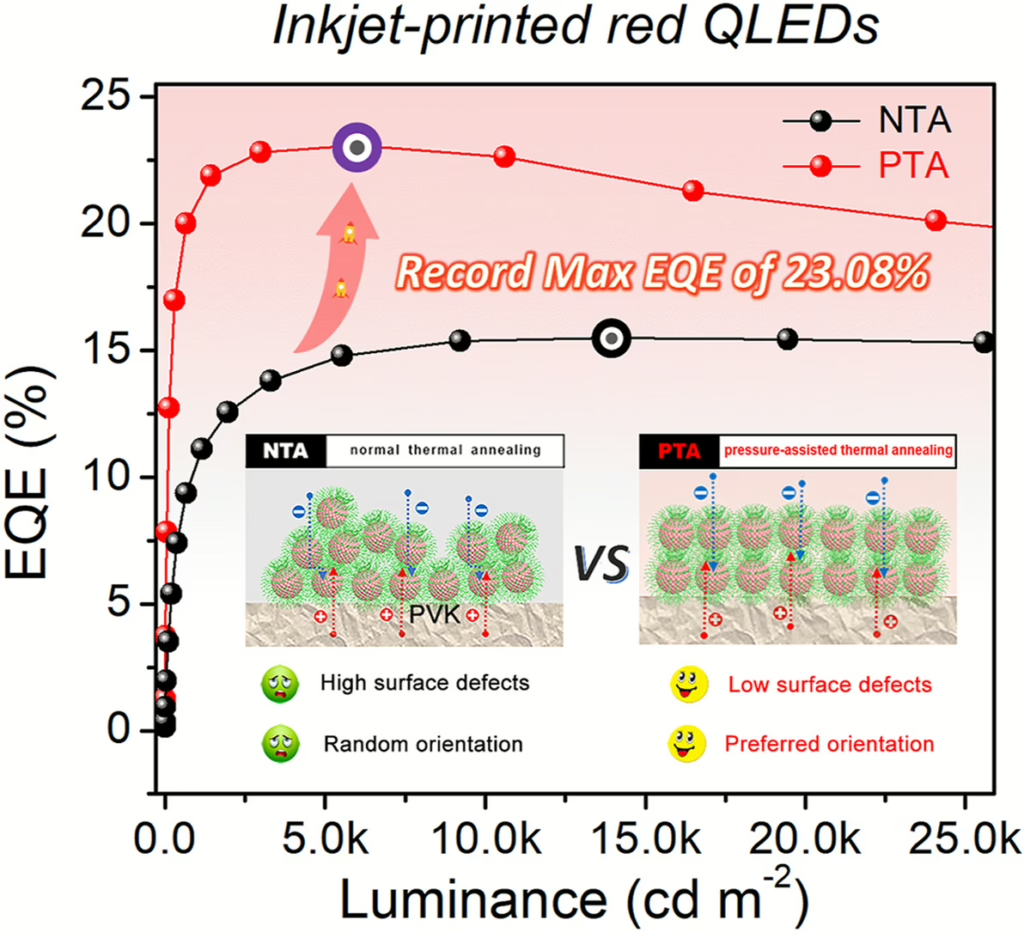

The researchers sought to develop a method to improve the quality of inkjet-printed QD thin films, enhance the efficiency and stability of inkjet-printed QLEDs, investigate the impact of a new post-processing technique, pressure-assisted thermal annealing (PTA), on the morphology and performance of QD thin films, and achieve record-breaking external quantum efficiency (EQE) and operational lifetimes for inkjet-printed QLEDs.

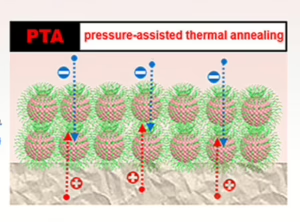

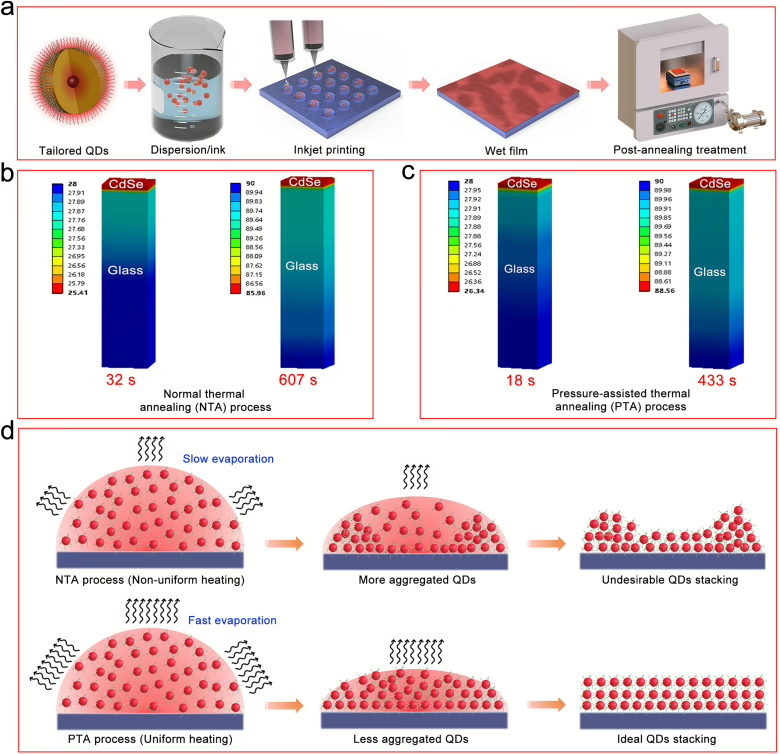

Their approach involved the synthesis of CdZnSe/CdZnS/ZnS quantum dots with gradient shells to optimize light emission and stability, inkjet printing of QD layers onto substrates using a carefully formulated ternary solvent ink, and the implementation of PTA, which involved vacuum-assisted thermal treatment to accelerate solvent evaporation, improve QD packing, and reduce surface defects. They also conducted material and device characterization using techniques such as transmission electron microscopy (TEM), X-ray diffraction (XRD), photoluminescence (PL) measurements, and electrical testing to evaluate the quality of QD films and the performance of the resulting QLED devices.

The study concluded that the PTA process significantly enhanced the quality and performance of inkjet-printed QLEDs by improving QD film morphology, enhancing optical and electrical properties, and achieving record-high efficiency and longevity. The PTA process resulted in highly ordered QD packing, lower surface roughness, and reduced defects. The PTA-treated films exhibited higher photoluminescence, better charge transport, and increased stability. The inkjet-printed red QLEDs achieved a record EQE of 23.08% with an operational lifetime (T50) of 343,342 hours, while the green QLEDs reached 22.43% EQE with a T50 exceeding 1,500,463 hours.

The researchers emphasized that their findings bring inkjet-printed QLEDs closer to practical application in large-scale, cost-effective displays and next-generation lighting technologies.

Reference

Wei, C., Xu, B., Zhang, M., Su, Z., Gu, J., Guo, W., Gao, X., Su, W., Cui, Z., Jeon, S., Fan, Z., & Zeng, H. (2024). Highly ordered inkjet-printed quantum-dot thin films enable efficient and stable QLEDs with EQE exceeding 23%. eScience, 4(3), 100227. https://doi.org/10.1016/j.esci.2023.100227