There are three ways to make money in the display industry: materials, processes, and products. Products are simple enough – make a TV or a gaming monitor. You need to have distribution and reach. Processes are very difficult – you have to commit enormous sums of money and predict which technologies can consistently deliver value over decades when you’re maybe 5-10 years away from realizing the full benefit of those technologies. You have to have long-term capital and a deep bench of knowledge and experience. Materials are what drives everything else, and where innovation is picking up pace because of the general interest in optoelectronics.

Thus, there is always ongoing research and efforts into creating new molecules and materials to improve OLED (Organic Light Emitting Diode) manufacturing. The development of highly efficient and stable blue OLED materials has been a major challenge in the OLED industry. Researchers are continuously exploring new approaches, such as thermally activated delayed fluorescence (TADF) emitters, phosphorescent emitters, and novel organic molecules, to create stable and efficient blue OLEDs.

Universal Display Corporation (UDC) stands as a prime example of a company engaged in research and development of new materials for OLED manufacturing. They have made significant strides in the development and commercialization of phosphorescent OLED (PHOLED) technology. The company has developed various phosphorescent emitter materials, including green, red, as well as blue emitters, which are typically organometallic complexes containing heavy metals like iridium or platinum. Furthermore, UDC has also made progress in developing host materials that enhance the overall performance of the emissive layer in OLED devices.

To that end, there’s an interesting pocket of research at Florida State University that has been doing work on ligand-engineering strategies that might be worth a shout out. The researchers have been focusing on the development and improvement of perovskite CsPbBr3 nanocrystals (NCs) and nanoplatelets as promising materials for OLED manufacturing. Metal halide perovskite NCs are particularly promising for next-generation display applications due to their high color purity over a broad range of wavelengths, high photoluminescence quantum yield (PLQY), and easy-to-implement synthesis.

Achieving the national television system committee (NTSC) standards for the three primary colors (blue, green, and red) is crucial for display applications. While significant progress has been made in green and red-emitting perovskite NC-based LEDs, the efficiency and stability of blue-emitting materials still need improvement. Developing blue-emitting perovskite materials with high PLQYs and long-term photophysical stability remains challenging compared to their green and red-emitting counterparts.

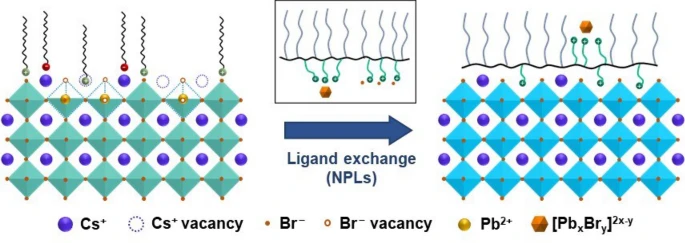

To address these challenges, researchers have introduced a surface ligand-engineering strategy using a multidentate imidazolium bromide polymer coating. This coating passivates surface vacancies and preserves the integrity of CsPbBr3 perovskite nanocrystals and nanoplatelets. To further enhance the stability of the material, the ligand is complexed with an additional bromide-based salt, such as PbBr2 or CoBr2, which helps overcome the damaging effects of etching while imparting colloidal and morphological stability.

Ligand engineering refers to the process of designing and optimizing molecules that bind to specific target molecules. The aim is to alter or control the function of the target molecule, either by enhancing or inhibiting its activity. Designing ligands that bind to specific semiconductor or conductor materials, may control the properties of the resulting material or its interactions with other materials. The design of ligands with specific binding properties enable the construction of molecular frameworks with predicted outcomes in terms of electronic, optical, or mechanical characteristics.

In this case, the surface ligand-engineering strategy uses PbBr2-complexed polymers with ammonium (or imidazolium) bromide anchoring groups and alkyl chains of varying lengths as solubilizing blocks. The presence of quaternary ammonium salts facilitates the dissolution of PbBr2 in organic solutions, forming polysalt-[PbxBry]2x−y complexes. These complexes strongly interact with the NPLs, eliminating surface defects and improving their structural and morphological stability compared to the as-grown materials.

To obtain colloidal blue-emitting CsPbX3 NCs, researchers can employ various strategies such as varying the molar fraction of the halide component using mixed Cl− and Br− cores, reducing the size of CsPbBr3 cuboids below the Bohr exciton radius, or growing anisotropic 2D quantum-confined nanoplatelets (NPLs). Growing NPLs, in particular, offers a promising strategy for achieving the desired deep blue emission in the optical spectrum due to the strong carrier confinement and tunable energy band gaps they provide.

As a result of these advancements, high-quality blue-emitting CsPbBr3 NPLs have been developed with maintained color purity (narrow profiles at ∼460 nm) and PLQYs up to 80% for nanoplatelets and near-unity for nanocubes. Additionally, the NPLs have demonstrated significantly enhanced long-term stability under challenging conditions, such as UV irradiation and highly diluted conditions.

The development of perovskite-based materials with these enhanced properties has significant implications for OLED manufacturing:

- Improved optical properties, such as high PLQY, contribute to increased light emission efficiency and color quality in OLEDs, making them more competitive with other display technologies.

- Enhanced morphological and colloidal stability makes these perovskite materials more robust and suitable for manufacturing OLEDs with longer lifetimes.

- The retention of crystal structure and morphology during the ligand-engineering process ensures that the desired optoelectronic properties of the perovskite materials are maintained, directly impacting OLED performance.

References

Vorajee, U., Donmez, S., Wang, S., & Mattoussi, H. (2023). Engineering highly fluorescent and colloidally stable CsPbBr3 nanocrystals of different shapes using imidazolium-based polysalt ligands. MRS Advances. https://doi.org/10.1557/s43580-023-00556-8

Wang, S., Wang, W., Donmez, S., Xin, Y., & Mattoussi, H. (2022). Engineering Highly Fluorescent and Colloidally Stable Blue-Emitting CsPbBr3 Nanoplatelets Using Polysalt/PbBr2 Ligands. Chemistry of Materials. https://doi.org/10.1021/acs.chemmater.2c00082