Most of the time on Display Daily in the last year or two, we have tended to talk about mostly about OLED, microLED and QD OLED, the new technologies that are changing the premium end of most high volume markets. But there’s a lot going on to keep improving LCDs which remains, by far, the dominant technology in terms of area shipped.

There are two key LCD technologies in the TV and monitor markets, based on IPS and VA liquid crystal technologies. Generally, IPS has better viewing angles and VA has better contrast, but those making each type are trying to catch up with the other. One of the mysteries of the display market over the last few months has been LG Display’s ‘IPS Black’ technology. IPS LC typically has typically had contrast from around 1,000:1 to 1,500:1 but LG claimed 2,000:1 – notably nearer to the 3,000:1 that is typical of VA panels. Unusually, though, LG Display told us that it didn’t want to say how it has achieved that level of contrast.

BOE and Merck Give Us a Clue

At Display Week, though, there were a number of papers from BOE and Merck presented in the Symposium that explain how you can go even further than LG has done. BOE talked about its ADS technology which is BOE’s version of FFS which itself is a variant of IPS. FFS itself was something of a niche technology that had been developed by Hyundai’s then panel business in the 1990s. It remained relatively niche until Apple adopted it for the iPhone. By then, the BOE Hydis business was part of E Ink which then licensed the technology to other panel makers.

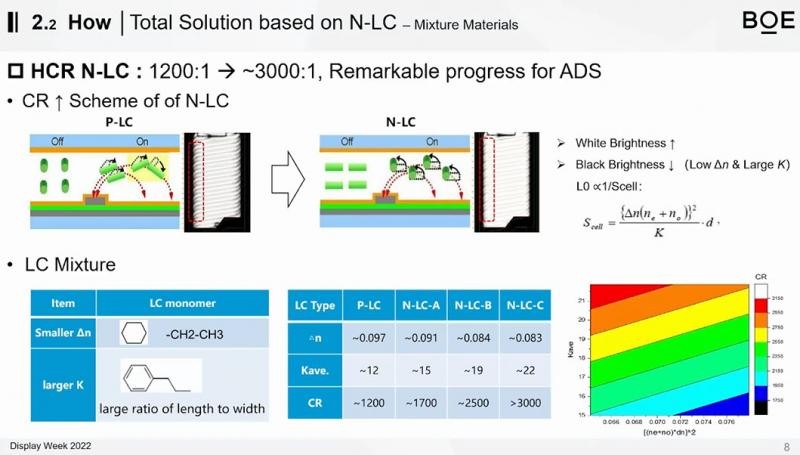

At Display Week, BOE talked about two different approaches to improving the contrast. In paper 34.6., BOE researchers from Beijing explained that they had changed the way that the liquid crystal operates. LCDs work by the orientation of the liquid crystal molecules acting as a kind of tap or switch to control how much light is let through to get different levels of grey or other colour. Usually, LCDs are designed to be positive – that is to say that when no voltage is applied, no light goes through. Applying voltage lets more light through. BOE felt that positive LC materials had basically reached their limit so it switched this around to a negative mode, where no voltage means all the light goes through and applying voltage closes the pixel down.

The molecules in the liquid crystal are also slightly tilted and that affects the viewing angle of the LCD. LCD makers use special techniques to get different parts of the pixel to tilt in different angles so that, on average, whichever way the light comes out of the pixel, it is more even and so the viewing angle performance is better.

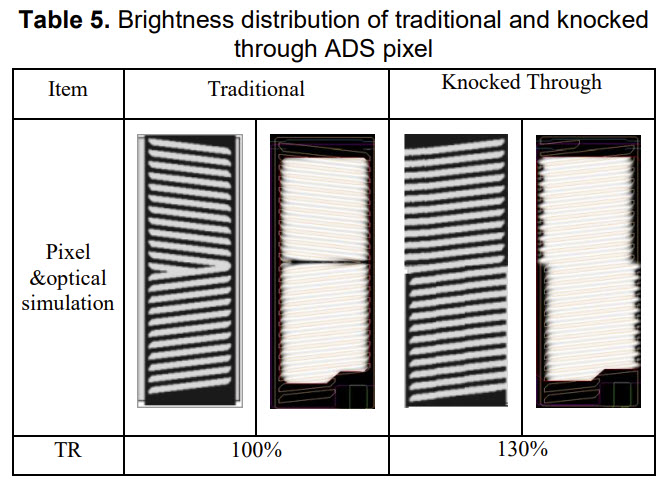

BOE said that its previous ADS panel used a pixel that is split into two domains with different alignment in each. In the new panel, the company moved to a four domain architecture with the four domains spread over four pixels. It also used what it calls a ‘knocked through’ pixel design to reduce the dark line across the middle of the pixel, between the two domains. That gets more light through which helps with contrast. It also reduced the black mask around the pixel that gets more light through. That’s especially important for 8K and BOE said it can get 8K panels to 2,500:1 contrast while 4K can get to 3,000:1.

The single domain with no dark line allows more light to go through the pixel

The single domain with no dark line allows more light to go through the pixel

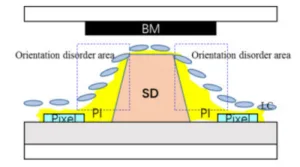

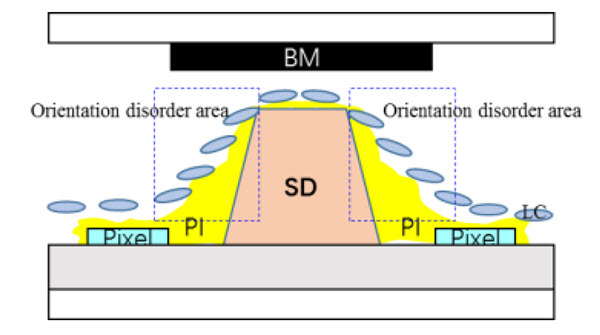

Another group from BOE Hefei (paper 34.3) in China took a slightly different approach. It also uses negative LC material to improve the black level and that is described as an ‘ultra-low’ scattering material. Whereas the Beijing group reduced the black level to boost the white, the group in Hefei slightly increased the size of the black mask. As shown in the diagram below, the black mask blocks more of the light that is going through LC molecules that are less well aligned (although it acknowledges that transmission is reduced which is not a positive change so a careful trade off needs to be made). The group also modified the alignment layer and improved the polariser to achieve 3,000:1 contrast.

The second BOE approach increased the black mask which reduces the light from less well aligned areas of the pixel

The second BOE approach increased the black mask which reduces the light from less well aligned areas of the pixel

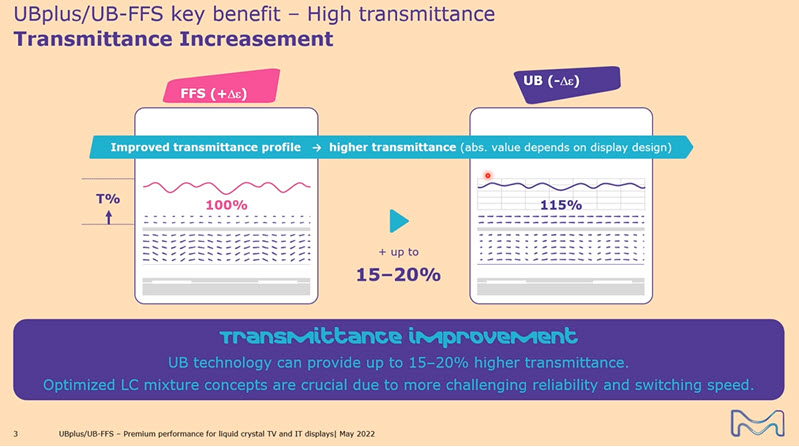

Merck is the dominant supplier of LC materials to the market and in paper 34.4 the firm described how the idea of using negative LC materials has been around for more than 20 years, the materials used not to be reliable enough for applications such as TVs and monitors. Merck, though, has been developing the materials to overcome this issue and talked about its latest UBPlus (for large displays) and UB-FFS (for small displays) materials which reduce the scattering of light but maintains the response time needed for monitor and TV applications. Response time had also been a challenge for these negative materials in the past and Merck said that it used to be double in its talk. The material boosts both the white level and improves the dark state to give better contrast.

In the past, Samsung’s TV business has seen some negative press coverage for using IPS panels in some of its TVs and has tended recently to send its IPS-based TVs to countries which may be less critical of this aspect. In store, VA has, up to now, had a visibly better contrast. Reducing the difference may make it easier for Samsung to buy LCDs from suppliers that are IPS-based such as LG Display without it being obvious in store.

However, VA panel and material makers have not been standing still, so we will come back on this topic to see how it is reacting to the competition from IPS/FFS. As usual, the winners are the customers who are seeing better and better displays. (BR)