There are many advantages to LCD displays – there is a reason it is the world’s dominant display technology. They are fast to refresh, with high resolutions and a slim stack (compared to legacy technologies like CRT and plasma). LCD keeps evolving to equal or beat its competitors. Quantum dots, allowing LCD displays to compete with the colour saturation of OLEDs, are just the latest example. However, there is one area where LCD struggles to improve dramatically: power consumption.

Much of the light (at leasat two-thirds) from an LCD backlight is blocked by the RGB sub-pixels; despite that, the backlight is usually on at all times to display an image. This makes LCD displays mostly unsuitable for use in applications such as wearables and eReaders, where low power draw is a necessity.

Reflective screens are much more efficient than (emissive) LCDs; not only do they use ambient light to display an image, but they can be bistable; when an image is on-screen, it draws no power. Reflective technology is common in eReaders; E Ink’s electrophoretic system is the most popular. E Ink (the technology) uses tiny particles, usually black and white, floating in a solution. Applying a positive or negative charge to the transparent top electrode will attract the corresponding particles to the top or bottom surface of the display, forming words and sometimes pictures.

While E Ink is stable and low power, it has inherent disadvantages. It is much more difficult to create colour than it is to make black and white (three-colour electronic shelf labels exist, using a microcup structure), and the refresh rate is very low. E Ink’s Advanced Color ePaper, shown at SID this year, has impressive colour but takes as much as 10 seconds to stabilise an image.

Other firms continue to work on reflective display technologies, such as Qualcomm (Mirasol and Pixtronix) and Sharp (MEMs display based on Pixtronix technology). Aside from the impressive demonstration given by ClearInk (here and here), though, these companies have mostly gone quiet in recent years.

That has not prevented new startups from entering the space, and one of these is Bodle Technologies: a spin-out from the University of Oxford. We first covered the firm back in 2014 (Display Monitor Vol 21 No 29) and I was recently able to go along to the company headquarters in the Begbroke Science Park in Oxfordshire, to see what it had been working on.

It might not look like the HQ of a company that might one day challenge E Ink, but there is some fascinating work being done in the Begbroke Science ParkOn arrival I was met by Richard Holliday, Bodle’s SVP of business development and intellectual property. He has years of experience in IP management and technology commercialisation, having previously worked on similar areas for the University of Oxford, the World Gold Council and British Steel. Later, I met CTO Peiman Hosseini and VP of displays Ben Broughton (formerly of Sharp which has a large research group in Oxford).

Bodle filed its first patents in 2013 and released an article in the journal Nature in mid-2014. Media and industry attention followed. Bodle worked to define potential applications for the technology, and raised £1.2 million ($1.6 million) in seed funding. Eight people are now employed, and that number is growing.

Click to enlargeAttention has been focused on the reflective display technology that Bodle has developed, based on phase-change materials; these are materials that change their state in response to an external stimulus, like heat or electricity. Originally this was germanium-antimony-tellurium (Ge2Sb2Te5), but now Bodle works with a range of phase change alloys, fine-tuning them for specific applications.

Click to enlargeAttention has been focused on the reflective display technology that Bodle has developed, based on phase-change materials; these are materials that change their state in response to an external stimulus, like heat or electricity. Originally this was germanium-antimony-tellurium (Ge2Sb2Te5), but now Bodle works with a range of phase change alloys, fine-tuning them for specific applications.

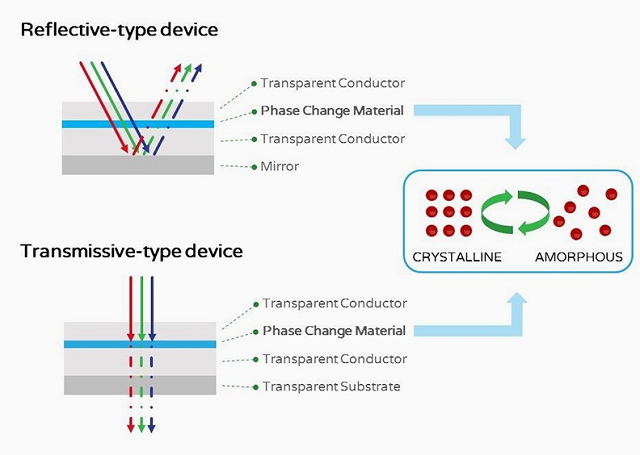

Bodle’s reflective technology (it refers to it as SRD: solid-state reflective display) is made up of a component stack, with a phase change material sandwiched between two transparent conductors, and deposited on top of a mirror. The phase change material can be in either an amorphous or crystalline form; one lets light through to bounce from the mirror, the other does not. A transmissive form is also possible, which uses a transparent substrate instead of a mirror; it can be used to reflect specific wavelengths of light, like IR. Any substrate – glass or plastic – can be used and materials are deposited through sputtering, a common method in the display industry. This use of existing materials and technologies will be a big advantage for Bodle when it comes to scaling production.

Unlike E Ink, the SRD can be switched extremely quickly: fast enough for video, or even holographic displays. It is also tunable to show ‘any’ colour; the colour produced depends on the thickness of the component stack. In a display, each pixel would feature three sub-pixels of different thicknesses to produce RGB colours. No pigments, filters or dyes are required.

Holliday showed me a diagram of colour gamut coverage, with CRT, plasma, LCD, OLED and SRD listed. SRD had a larger gamut (156% sRGB) than any of the others, even OLED, although it was skewed more towards light green than dark. This was an old image, however; the colours are tunable to any shade. The colours are more metallic than some other technologies, which makes them appear brighter but could also make some images less accurate.

Pixels in the SRD are very small: nanometer-scale. This means that the technology is well-suited to applications like small AR and VR displays, although this is not a focus for now; Bodle may look at it more after Series A funding. The disadvantage to these tiny pixels is that applying them to a large display at high resolutions is expensive and complex. Having so many pixels on a large display requires a lot of power to drive a big screen. Bodle is currently scaling pixels up for other applications, and believes that it can create millimeter-scale types.

I was very impressed with what I saw at Bodle. The (very early) prototypes, which are currently simple blocks of colour, were rich and vibrant. Turning them into a display will take more work, and Bodle has still not settled on a business model, although licensing IP seems like a sensible approach. Prototyping will take place over the next six months.

– Tom Allen