Just before Display Week, I managed to catch up with Peiman Hosseini, a founder of Bodle Technologies, a technology start-up that is developing bistable displays. The company is developing a display application that exploits a material science discovery made by him and Prof. Harish Bhaskaran.

We have reported on the company regularly since the firm was founded in 2015 after an article was published in Nature in 2014, although I hadn’t spoken to the firm myself.

Hosseini took over as CEO of Bodle in July, taking over from Mike Clary, who will stay on the board of the firm.

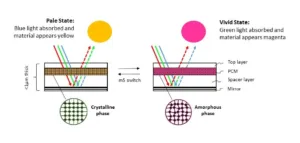

Hosseini started by explaining that he wasn’t looking for a display application when he spotted an optical effect in a phase change alloy. When he went to check on the effect, he found no literature and realised that it was a new discovery. The idea is to use an electrical stimulus to change the refractive index of a very thin film of material to control the colour of reflected light, from a mirror and using a nano-cavity to control the colour. The stimulus is a microsecond pulse which is relatively high amplitude, but short.

The change in index can be reversed and is stable, so displays built on such pixels are bistable – they only need power when changing, not to maintain an image.

The materials and deposition methods are similar to those used in the optical disc industry, so there is a huge amount of over capacity because of the drop in the demand for optical storage such as DVDs and CDs. There is a lot of ‘know how’ in Asia in these areas, such as PVD sputtering so Bodle has been looking east.

To build a display, you need a backplane with reasonably high mobility to allow fast switching and it is something of a lucky coincidence that there is currently plenty of overcapacity for LTPS backplanes and Hosseini told us that ‘only slight tweaks’ are needed to optimally drive its displays, and its first prototypes used completely standard substrates from Tianma.

Because the processes used to make the displays is very similar to that used in the optical industry, it is possible to get into production with very low capex.

The firm has been working with ITRI in Taiwan and just as we published this article, the company put out a press release highlighting its work with ITRI (Bodle Technologies Announces World’s First TFT Driven Solid State Reflective Display® Fabricated on a GEN2.5 Line). The firm’s own development line can produce ‘hundreds of samples per month’ and the company can scale up production very rapidly. Hosseini estimates that it will take around 18 months to get into full production.

As a bistable technology, displays for eReaders are a longer term prospect, but the firm’s initial target market application is ESLs. The advantage here is that the incumbent technology, E Ink, has some challenges to develop more colours, whereas Bodle can make different colours using interference effects in its optical layer. I see this as ‘Iridigm without the mechanics’ for those that have been around long enough to remember that technology. The ability to have different custom colours for very small production runs is a key competitive advantage in the ESL application.

Bodle originally started with the idea of just licensing its technology, as time has gone on, it has realised that it can make displays as the substrates can be purchased and the film deposition process can be sub-contracted. That allows the accumulation of more ip in the manufacturing processes and materials. However, it is still open to a licensing approach.

Eventually, the firm would like to get its displays into eReaders and video, but this will need more development. At the moment, the displays are robust in terms of mechanical handling and temperature, but at the moment there are limits in the number of times the material can be changed.

ESLs typically need to be able to change three times per day for three years, and typically specifications will call for a life of 10K changes. As Hosseini said, the materials used in storage have been tested for billions of cycles in writable DVD, so he believes that eventually his materials may get to the same level, which would open the way for video at low power. (BR)