Adam Ellison was the second speaker from Corning and he has worked on the firm’s glass for TV and large screen projects for some time. Corning has a number of basic glasses and the main ones for displays are:

Adam Ellison was the second speaker from Corning and he has worked on the firm’s glass for TV and large screen projects for some time. Corning has a number of basic glasses and the main ones for displays are:

- Eagle XG which is 90% of its volume and is intended for amorphous-silicon

- Lotus XT is for poly-silicon and is 10% of its volume

Gorilla Glass is mostly Eagle XG. The thickness of the substrates has gone down from 0.9mm initially, when first used in LCD TVs, and has reduced to the point where Corning is now working with clients on 0.3mm and 0.4mm thickness glass, although Corning’s Willow Glass is also available for “really thin” applications.

There is a lot of work going on to drive down panel and TV cost to help develop the market for bigger LCDs. Corning sees OLED remaining a niche in terms of the glass market. Ellison’s main topic was light guide plates, which he then turned to.

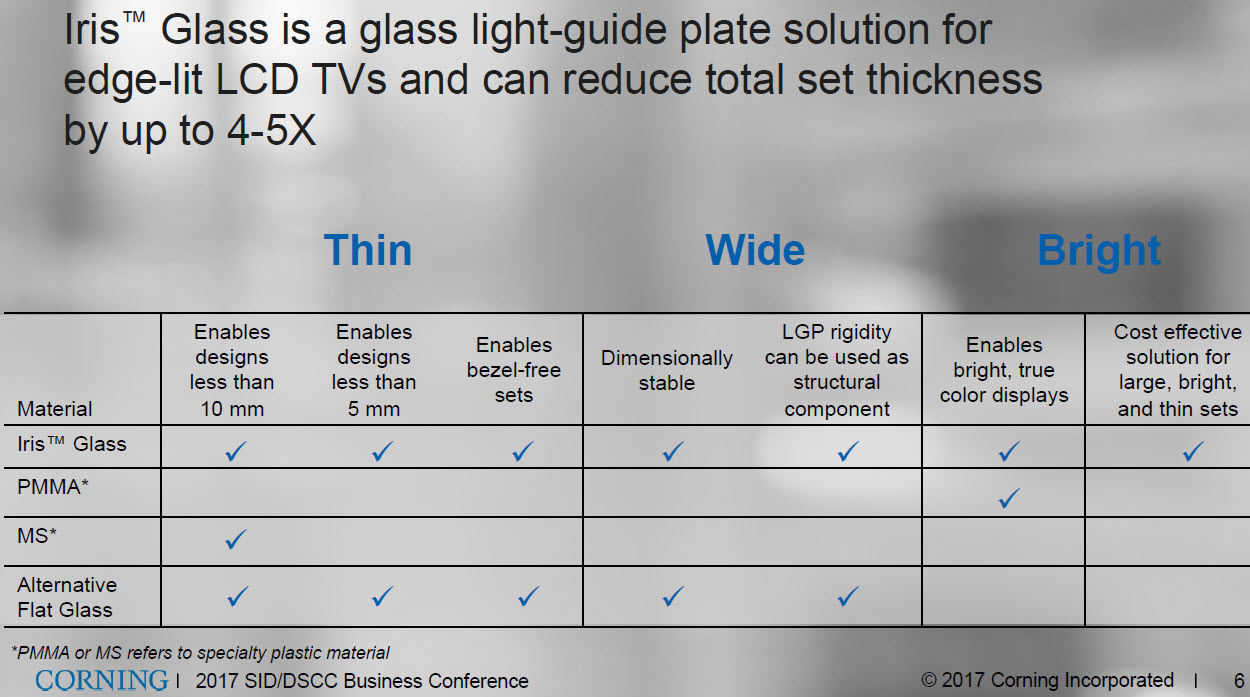

Edge-lit panels are easier to make slim but there is a big trend to slimmer sets, which, clearly, consumers like. Six of the LCD TVs for the Chinese market to be introduced this year will be 5mm or thinner, he said. Plastic LGPs start to struggle with thermal issues at very large sizes and so, if the industry switches to making 55″ and 65″ sets, that is to the advantage of Corning and its Iris Glass which has a much lower coefficient of expansion than plastic.

Glass is also quite stiff, the Iris glass has an elastic modulus the same as aluminium, Ellison said, and so it can be used as part of the mechanical structure of the set, something you can’t do with plastic light guides. Corning has had to work with OEMs and ODMs to help them to understand how to exploit this feature.

On a 65″ set, the LGP expansion from the backlights can be as much as 5mm to 6mm under heating and you can also have problems with different parts of the display thickening differently, because of the thermal differences. The plastic LGPs can also be sensitive to water absorption, which, again, can be quite different on different parts of the set. Corning’s Iris glass can also stand high temperatures, so the plate can be put close to the LEDs. This can actually be helpful in optically coupling the light from the LEDs into the plate. Iris glass is claimed to have lower colour shift than plastic materials.

Sometimes, exploiting all of these issues, the BOM cost can be brought down to the level of a mainstream LCD. However, the design can be made very close to the look of an OLED and may command a premium over other sets.

The company is very optimistic about future developments of Iris glass.