One of the key components desired in a display that is both flexible and transparent is a polymer material that is itself flexible and that presents optical and thermal properties similar to that of glass. A research team at the Korea Advanced Institute of Science and Technology (KAIST) (Daejeon, Republic of Korea) is engaged in the development of such a material.

A recent article on this topic by the team is entitled “Poly(amide-imide) materials for transparent and flexible displays. The article was published on-line in Science Advances 26 Oct 2018: Vol. 4, no. 10, eaau1956. A copy of the article is available on-line and can be found here.

First, a few words of background information paraphrased from the team’s article.

One of the problems that make it difficult to find a polymer with the desired properties is because non-cross-linked organic polymers have a relatively large Coefficient of Thermal Expansion (CTE). Values typically fall in the range of from 30 to 400 ppm/°C. Other materials in the display, such as ceramics and metals, typically have CTEs that range from 0.5 to 25 ppm/°C. Due to this mismatch, the device can crack when the temperature changes, inducing stresses generated by thermal expansion and contraction. It follows that matching the CTE of the component materials is a very important factor in the design of a viable flexible and transparent display device.

Non-cross-linked organic polymers have large CTEs because the interactions between individual polymer chains are weak and they therefore experience substantial thermal expansions upon heating. To address this issue, the team’s research started with the observation that thermal expansion and contraction of polymer films could be minimized by introducing interaction forces between the polymer chains and by arranging the direction of the force to be perpendicular to the long axes of the chains. The team successfully implemented this approach with an appropriate design of the chemical structure of a flexible and transparent polymeric material called poly(amide-imide).

The team developed novel poly(amide-imide) materials having a transparency of about 90% and CTE values as low as 4 ppm/°C. This is an exceptionally low CTE for a non-cross-linked, amorphous polymer – especially since the material retained high transparency and exhibited excellent thermal and mechanical properties. More than this, the team found that the CTE values could be precisely tuned in the range of from 4 to 20 ppm/°C by controlling the fraction of “asymmetrically positioned trifluoromethyl groups in the polymer backbone.” It was reported as possible to accomplish this tuning without degrading other desirable material properties.

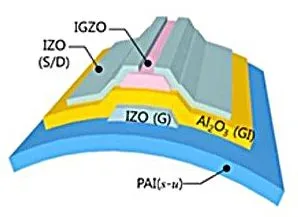

A film of the new polymer demonstrated sufficient thermal stability to withstand the process used to fabricate Indium-Gallium-Zinc Oxide Thin Film Transistors (IGZO TFTs), a process that can expose the film to temperatures in excess of 400ºC. The schematic below illustrates the structure of a transparent and flexible IGZO TFT device fabricated on a substrate made from a specific type of poly(amide-imide) called PAI (s-u).

Schematic structure of the transparent and flexible IGZO TFT fabricated on PAI (s-u).

The researchers confirmed that the device could indeed operate normally even when folded down to a radius of 1mm.

The researcher conclude their article with the observation that they have “demonstrated the potential of this new material as a versatile platform for electronic devices that require flexible and transparent form factors.” More generally and in addition, that “the method developed for amorphous polymers with a controlled CTE can be applied to control the thermal expansion of organic materials as well.” -Arthur Berman

Korea Advanced Institute of Science and Technology, Sun Dal Kim, [email protected]