It’s no secret that the quantum dot industry has a love/hate relationship with the element cadmium (Cd). It is a common element used in QD technology, and QD types that utilize Cd (CdSe in particular) are by far the most studied materials.

That study has led to impressive performance metrics and Cd-containing materials were the first types of QDs used in displays and lighting. However, it is widely accepted that cadmium (along with the likes of lead, mercury, chromium) are undesirable from a safety standpoint.

In 2003 the EU adopted the Restrictions of Hazardous Substances (RoHS) directive to limit the concentration of hazardous materials in electrical and electronic equipment. Cadmium is, of course, on this list and is limited to a concentration of 100 parts per million (ppm) in any component or part. Yes, even though you may see logos that imply zero concentration of these elements, there can actually be a limited amount of them present while still being considered RoHS compliant.

There are currently dozens of exemptions to the RoHS regulations, such as mercury in CFLs, lead in solders and steel, and more which are only allowed after thorough evaluation of the benefit the technology offers compared to any alternatives that do not contain hazardous substances (if available). The Oeko (Öko) Institute is often called upon by the European Commission to evaluate exemption requests and make recommendations to EC policy makers.

These recommendations may or may not be followed as local and regional politics can of course shape how individual member states vote. Cadmium has had a longstanding exemption (with multiple modifications) since 2013 specifically for QDs in displays and lighting due to the enhanced efficiency of displays with Cd-containing QDs. But that run may soon be coming to an end.

Oeko Makes its Recommendation

In a public report published on the European Commission RoHS site it appears that Oeko Institute provided their recommendations to the EC late last year. This 70 page report outlines the arguments and calculations performed by Oeko, company stakeholders, and applicants, all of whom can have vastly different views on the topic of the cadmium exemption. This included QD companies, phosphor/LED providers, and industry groups. I want to give a ‘shout out’ to Professor Jonathan Owen of Columbia for the heads up on this report.

Before I get to the recommendation, it is important to understand the current status of the exemption in both displays and lighting.

With the current exemption, cadmium is limited to 0.2 ?g (micrograms) of Cd per mm2 of display area. This means a ~60 inch TV (1 square meter) can have up to 0.2 grams of cadmium, allowing for QD films containing CdSe QDs for both red and green down-converters can be utilized (which are currently on the market).

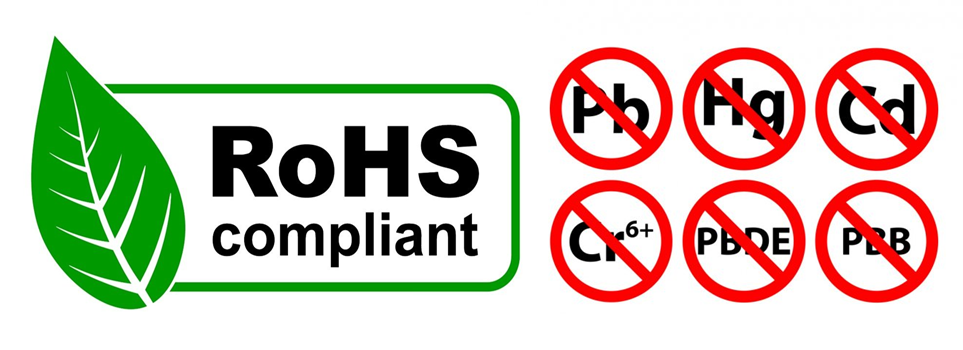

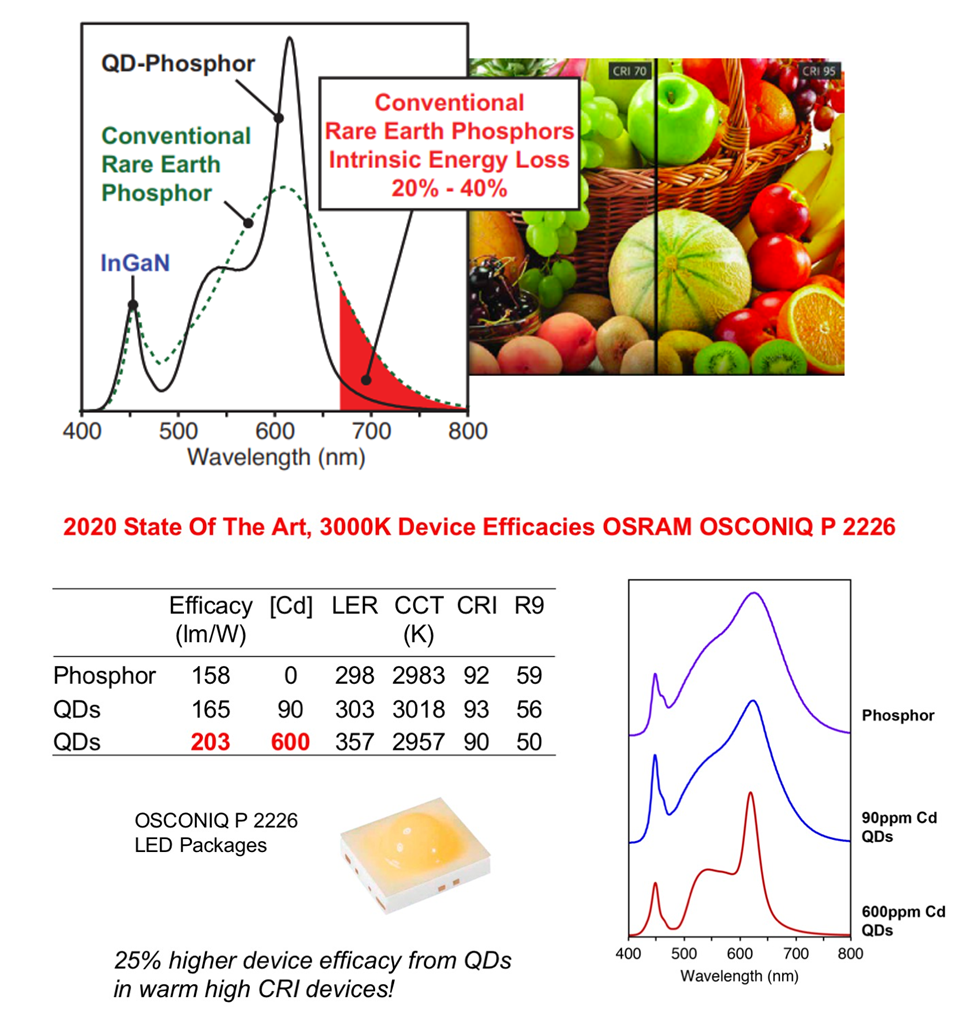

Importantly, there is currently NO EXEMPTION for cadmium in lighting products, which is why the Osram LED lineup contains only a limited amount of Cd-containing QD material, mixed with other phosphor material to achieve the desired color and <100 ppm Cd. It is important to note that if an exemption were allowed to a higher limit of Cd, then the overall efficacy of these LEDs could be greatly improved. The improved efficacy comes from a reduction in unused IR photons when using a narrow red QD phosphor.

KSF phosphor would also offer a similar benefit as it also offers narrow red emission. An analysis from a 2020 DoE report on narrow-band red emitters shows that LEDs containing KSF phosphor from GE may actually result in greater efficacy than RoHS compliant LEDs containing QDs (note, tests were with different color temperature and devices so not exactly apples to apples). Interestingly, both showed lackluster performance in reliability at high humidity (75C/75%RH).

LEDs with higher Cd QD concentration show much improved efficacy, a full 25% increase over devices with no QDs. Source: Jon Owen 2020 DoE SSL Workshop Presentation

LEDs with higher Cd QD concentration show much improved efficacy, a full 25% increase over devices with no QDs. Source: Jon Owen 2020 DoE SSL Workshop Presentation

I bring up the topic of lighting as Osram provided most of the data that was relied upon for Oeko to develop their recommendations, and Osram has the most to gain/lose based on the outcome (to my knowledge there is no other supplier that has commercialized a QD-downconverter for lighting). An exemption for lighting at higher Cd limits would mean they can implement their high-Cd devices with improved efficacy. No exemption would mean they remain limited to the small gains achievable within the 100 ppm Cd limit.

So what did the report recommend? Drum roll please…

Oeko recommends that the current exemption be removed for QD film type applications in displays with a 12-month grace period. If adopted, this would mean that QD films using combined red and green Cd-containing QDs would most likely no longer be RoHS compliant and would need to be removed from the market within a year. The main argument for this decision was the comparable performance and availability of non-Cd QDs (InP mainly). Importantly, there already exist RoHS compliant films leveraging ultra-low Cd-containing green QDs, and non-Cd red QDs (for example Nanosys Hyperion) which remain below 100 ppm cadmium (no exemption required).

Oeko also recommended two new wordings for new exemptions. One for lighting, and one for display. Both are limited to the use of QDs directly on top of an LED, aka “on chip” (If you recall, my article a few months ago pointed out that QDs on chip might be making a comeback).

LIGHTING: For lighting applications the recommended limit is worded as “< 1000 ppm in the luminescent material.” This presumably means that Osram would be able to implement higher CdSe QD loading to achieve greater efficacy increase. The decision was based on enhancements to overall efficacy, and the lack of suitable alternatives (other QD types are not viable on chip).

DISPLAY: For display applications the recommended limit is worded as “5 ?g Cd per mm2 light emitting LED chip surface.” It’s unclear exactly how this should be interpreted and how it was determined, but what is clear is that other strategies to implement QDs (film, color filter, etc) are not included here.

Lots of data and input were considered by Oeko when making this recommendation, too much to summarize here. If you are interested in a more in-depth analysis, please feel free to contact me.

It is important to note that this is only a recommendation. It is not automatic that this will be adopted by the European Commission. In the past the EC has asked Oeko to go back and solicit additional input which resulted in a new recommendation. If the recommended changes do sail through and become adopted, then we could see the end of R/G Cd-containing QD films in displays as soon as 2022.

What About Perovskites?

Some of you might be wondering about lead-based perovskites. Lead is also on the RoHS list, but the default limit is a higher concentration; 1000 ppm. The green-only QD film-based perovskite technologies being developed today will likely be <1000 ppm Pb, which would not require an exemption. However, for future technologies such as QD color filters/color converters (think QD-OLED) the concentration of lead could become a contentious issue.

One closing thought. Even though this recommendation is a strong signal for the end of Cd-containing QDs in displays, it’s not going to have a big impact on the overall technology since alternatives such as InP are already mature and continue to improve. QDEF, QLED, QD-OLED, EL-QLED, whatever you want to call it – it’s not going anywhere. (PP)

Peter Palomaki is the owner and chief scientist at Palomaki Consulting, a firm specializing in helping companies solve big problems at the nanoscale. His utilizes his expertise in quantum dots and materials chemistry to solve challenging problems with clients large and small.