“After more than three years of hype, excitement, and unfulfilled promises, miniLED backlights are finally ready for prime time,”asserts Taha Ayari, Technology & Cost Analyst at System Plus Consulting part of Yole Développement (Yole).And he explains: “MiniLED monitors, and laptops have been available since late 2020. Most leading TV brands are adopting miniLED backlights in their 2021 flagship models. The highly anticipated miniLED Apple iPad Pro was officially announced in April 2021.”

In this context, the reverse engineering & costing company, System Plus Consulting announces today an in-depth analysis of the miniLEDs and their assembly in the display’s backlight unit of the 12.9-inch iPad Pro, 2021 edition. The company provides a full reverse costing study of the miniLEDs and their assembly in the backlight unit of the display.

This report provides valuable insights regarding the technical choices made by Apple and the supply chain behind. It includes technology data, manufacturing cost, and selling price of the BLU, with a focus on the miniLEDs and their drivers. This analysis also highlights an estimated manufacturing cost of all the BLU’s components and a selling price analysis.

Properly designed miniLED backlights allow LCD displays to reach contrast performance close to that of OLEDs , while maintaining the high brightness characteristics of LCDs. All of this while offering reduced power consumption, a very thin form factor (thickness), and cost/price competitiveness with OLED.

“With this newest iPad Pro, Apple is really bringing this newer display technology to the consumer”, comments Youssef El Gmili, PhD., Director, Laboratory Department at System Plus Consulting. “As many different supply chain and technology choices are not settled yet, this System Plus Consulting teardown report provides great insights into the choices Apple is bringing to the table.”

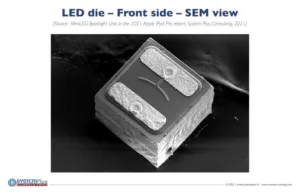

The new backlighting system is composed of 10,384 miniLEDs divided into 2,596 local dimming zones. The miniLEDs, which are GaN-based dies on patterned sapphire substrate, have an engineered light-emission pattern using dedicated top and back dielectric reflectors.

“At System Plus Consulting, we think that they are manufactured by Epistar in Taiwan”,announces Taha Ayari… This foundry has been created in 2017 in Taiwan. Its capacity is mainly focused on discrete LEDs, on 100mm wafer size. System Plus Consulting report presents the detailed process flow of the miniLEDs and proposes a key cost analysis. This front-end analysis combines the following costs: wafer, equipment, consumable, labor, clear room and yield losses. The die cost analysis is a combination of front-end cost, probe test & dicing cost and yield losses.

COB assembly of the more than 10,000 miniLEDS is believed to be done by TSMT in Taiwan.

The miniLEDs are mounted in flip-chip configuration. The miniLEDS are driven by nine drivers from STMicroelectronics. These drivers are wafer-level chip-scale packaged. System Plus Consulting report also delivers a detailed cost analysis of the drivers. Youssef El Gmili confirms: “The main part of the backlight unit cost is due to the mini-LEDs at 37%…”

And the backlight unit is also part of System Plus Consulting cost analysis.

Eric Virey and Zine Bouhamri, PhD. and Analysts at Yole have supported the System Plus Consulting’s team during its investigation. Both analysts published in 2020 a dedicated technology and market report, Next Generation TV Panel Technology & Market Trends.

Today, they comment the technical choice made by Apple and give their analysis of this backlight system including, for the 1st time, a miniLED technology. Discover their article: Deep dive into Apple’s iPad Pro’s miniLED backlight: how the company balanced cost and performance.

All year long, Yole Group of Companies, including System Plus Consulting and Yole Développement publishes numerous reports and monitors. In addition, experts realize various key presentations and organize key conferences.