The requirements on displays for a wide range of device and product applications are only going one way: to more pixels arranged in smaller physical areas and consuming less power. One approach with real potential to meet these requirements is InGaN-based MicroLED displays.

Unfortunately, it has been found that, as the size of the pixels in a MicroLED decreases, so does device efficiency. Lower efficiency causes higher power consumption. High power consumption can, in turn, induce self-heating during display operation, a shift in the emission wavelength and a decrease of external quantum efficiency.

A team of researchers headed by Woo Jin Baek of the School of Electrical Engineering within the Korea Advanced Institute of Science and Technology (Daejeon, Republic of Korea) or KAIST have undertaken research to investigate this topic and address these issues. (Note: This research was conducted with the support of the Samsung Future Technology Development Center.)

A recent article on this topic by the team is entitled “Ultra-low-current driven InGaN blue micro light-emitting diodes for electrically efficient and self-heating relaxed microdisplay.” It was published in Nature Communications (2023) 14:1386 1.

Ultra-Low-Current InGaN Blue MicroLEDs for Enhanced Electrical Efficiency and Self-Heating

The light emitting material in the subject LEDs is gallium nitride. An epitaxy process is used to produce a continuous stack the gallium nitride crystals on top of an ultra-pure silicon or sapphire wafer substrate. The next step is to form the pixels by cutting the epitaxial stack using a plasma-based etching process. The plasma etching process can, however, create defects on the sides of the pixels. This effect becomes more significant as the pixel become smaller because smaller pixels have a higher ratio of pixel surface area to pixel volume. Since the number and density of edge defects increases along with the proportion of side area, the efficiency of the MicroLEDs will decrease as the pixels get smaller.

A great deal of research has been conducted to develop means to mitigate the effects of these side or lateral defects. Note that, up to now, most of these approaches are intended to be applied during post-processing – after the pixels have been formed. Such approaches have shown little ability to reduce defect density or the effects caused by the defects. It is for this reason that, in their recent research, the team investigated an alternative approach. It was focused on the epitaxial stack itself.

The technical explanation for the new approach is described in the team’s article as embodying “strategies for epitaxial structure engineering that carefully considers the quantum barrier layer and electron blocking layer to alleviate efficiency degradations in low current injection regime. This is accomplished by reducing the lateral diffusion of injected carriers via reducing the tunneling rate of electrons through the barrier layer and balanced carrier injection.”

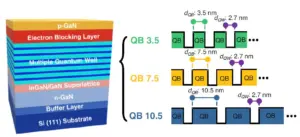

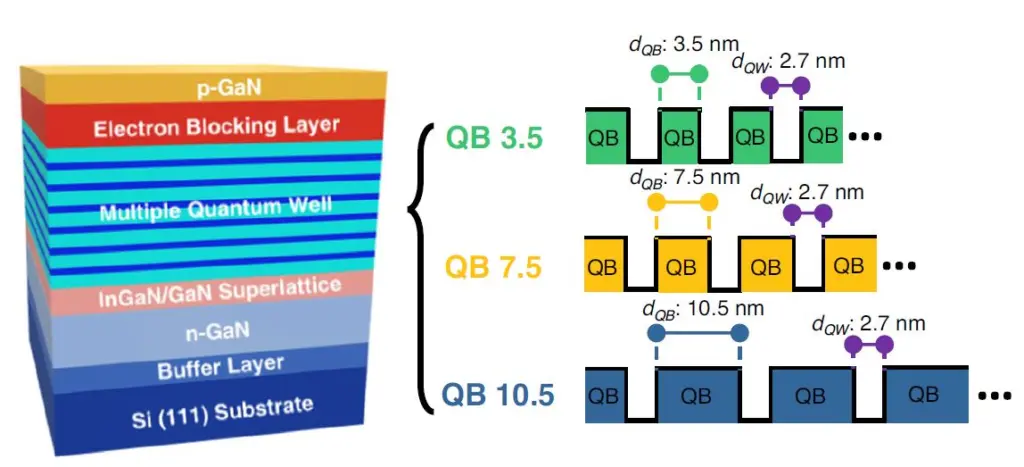

The schematic below illustrates the epitaxy structure and active region structure of the LED with different quantum barrier (QB) layer thicknesses.

Utilizing this new approach, prototype MicroLEDs fabricated by the team demonstrated a high external quantum efficiency of 3.00% at 0.1 A/cm2 for the pixel size of 10 × 10 μm2. A negligible shift was found in the current density at maximum external quantum efficiency as the pixel size was reduced. In conjunction with this, the team reported that their epitaxy strategies mitigated self-heating of the MicroLEDs and that the average pixel temperature was effectively reduced. More specifically, the proposed structure could reduce the heat generated during display driving by about 40% compared to the conventional structure.

The research team concludes their article with the statement that “This technology development has great meaning in identifying the cause of the efficiency drop, which was an obstacle to miniaturization of micro LED, and solving it with the design of the epitaxial structure, and it is expected to be used for ultra-high resolution displays in the future.”

Reference

Baek, W.J., Park, J., Shim, J. et al. Ultra-low-current driven InGaN blue micro light-emitting diodes for electrically efficient and self-heating relaxed microdisplay. Nat Commun 14, 1386 (2023). https://doi.org/10.1038/s41467-023-36773-w