“Selecting and Customizing Display Products,” held by the SID Los Angeles Chapter in Costa Mesa, California on February 8, 2019, was the latest in a long-running series of annual one-day display conferences. The last speaker of the day was Anthony Nichol, CTO and co-founder of FLEx Lighting, with headquarters in Chicago 18 sales offices in North America and Asia (Fig. 1).

Fig. 1. Anthony Nichol, CTO of FLEx Lighting and speaker at the 2019 SID-LA One Day Conference “Selecting and Customizing Display Products.” (Photo: Ken Werner)

Fig. 1. Anthony Nichol, CTO of FLEx Lighting and speaker at the 2019 SID-LA One Day Conference “Selecting and Customizing Display Products.” (Photo: Ken Werner)

FLEx’s technology is very thin lightguide films, and the title of Nichol’s presentation was “The Frontlighting Alternative for Reflective LCDs.” Nichol quickly established that he was not proposing frontlit reflective LCDs (RLCDs) as candidates for HDR television displays. Rather, he said, they offer superior performance to transmissive LCDs in sunlight, and much greater efficiency than transmissives when the edgelight is on. The challenges that had to be overcome were contrast, color reflectivity, viewing angle, and the design of the frontlight.

Nichol compared the performance of E Ink’s Carta electrophoretic display (EPD) with that of a JDI 4.4-inch memory-in-pixel (MIP) reflective LCD display. As is well known, the EPD has Lambertian reflection, which means it reflects light equally through a wide range of angles. This produces the paper-like appearance for which EPDs are famous. The reflectivity of the Carta display film is 44%, with a 15:1 contrast ratio (CR). If you were to put an RGB color filter on the display, you would have an angularly uniform reflectivity of 13% and a CR of 7:1.

(E Ink used to exhibit such displays, but the colors were dark and muddy, as the specs suggest. E Ink no longer shows such displays, and has been developing displays with inherent color that do not require filters.)

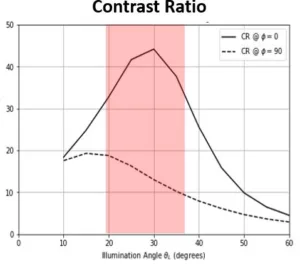

If the color RLCD is illuminated with diffuse, essentially Lambertian, light, its performance is even worse than the EPD: 7% reflectivity and 5:1 contrast ratio. But if you use narrow-beam illumination and do careful measurements, you find that the reflectivity and CR vary strongly with the angle of incidence for these displays (Fig 2a and Fig 2b). At the optimal angle, reflectivity is 18% and CR is 40:1, which is good enough for a variety of applications that require sunlight readability, low power consumption, and moderately good color under low illumination. With that understood, it was necessary to create a lightguide film that delivered illumination from the frontlight to the display at the optimal angle.

Figs. 2a and 2b: The reflectivity and contrast ratio of a reflective LCD vary with the angle of the incident light, which provides a mechanism for optimizing frontlight performance. (Graphics: FLEx Lighting)

Nichol said the required light-guide film, although very thin, has multiple optical layers, nano-patterned light extraction features, and a large optical mixing zone that is folded under the display so it does not take up space. (Note: I have spent a lot of time as an expert witness on light-guide design. I can be real bore if you get me started.) Nichol says the design offers precise control of lighting angles without brighness enhancing film (BEF). The technology is well established, the company has major display customers, and FLEx has has roll-to-roll manufacturing plants in Lamphun, Thailand and Twinsburg, Ohio.

Who said you can’t manufacture anything in Ohio? – KW

Ken Werner is Principal of Nutmeg Consultants, specializing in the display industry, manufacturing, technology, and applications, including mobile devices, automotive, and television. He consults for attorneys, investment analysts, and companies re-positioning themselves within the display industry or using displays in their products. He is the 2017 recipient of the Society for Information Display’s Lewis and Beatrice Winner Award. You can reach him at [email protected].