For the first time I feel like there is serious commercial momentum behind electroluminescent QLED. I’ve written about EL-QLED many times before, but the take away has always been that there is a long way to go before these become commercial. This year at SID Display Week I felt like there was a shift in the conversation from “how much longer until this is viable?” to “what will be the first application that adopts this technology?”

For starters, there were several high-quality talks by companies and universities highlighting the advancements in EL-QLED. I chaired two such sessions where scientists from Samsung, TCL, BOE, and Sharp all shared incredible progress towards manufacturing displays with electrically driven R/G/B QD pixels.

The real eye candy, however, was on the show floor.

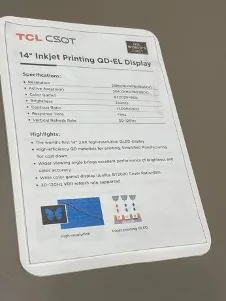

TCL showcased a 14-inch QD-EL laptop screen fabricated by ink-jet printing. It dazzled viewers with beautiful colors and excellent viewing angles. Even blue colors (which are the weakest link in EL-QLED commercial readiness) appeared bright and pure. The 350-nit brightness appears to be sufficient for a commercial product as it was not hidden in a dark corner of the booth. Frequent readers or those in the display field know that TCL CSOT is betting big on IJP as a future manufacturing approach. I will say that the EL-QLED display and the handful of IJP OLED displays in their booth looked equally great.

TCL’s demo at Display Week 2024. (Source: Peter Palomaki)

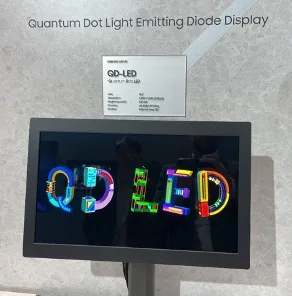

Samsung had a monitor-sized 18.2 inch demonstration of their Cd-free “QD-LED.” This one also manufactured by IJP. The fact that both Samsung and TCL are adopting the IJP approach should tell you something. The color gamut was said to be >90% of BT2020, which in my book is about as far as is necessary for most applications. And is pretty impressive considering these QDs do not contain cadmium which can provide a narrower peak emission. When I discussed the initial market for QD-LED with a Samsung EVP, they said monitors or laptops will be their first stop. While the demo used a polarizer, interestingly they said their preferred approach would be to apply color filters on the QD pixels, rather than a polarizer. This would result in reduced cost while maintaining higher brightness.

Samsung’s demo at Display Week 2024. (Source: Peter Palomaki)

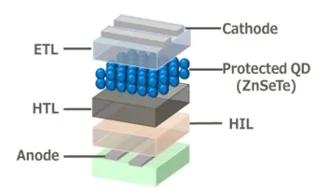

Sharp published a paper with Nanosys co-authors describing their photolithography approach to producing “NanoLED” which is their term for EL-QLED or QD-EL. They showed their display in the privacy of their own demo room which I was fortunate to have been invited to view. Two displays were shown, both unique in their form factor. Brightness was not as high as the TCL and Samsung demos, but this could be due to the manufacturing method. The approach Sharp uses is distinctly different than the approach taken by TCL and Samsung. Sharp is making the bet that fabs will be able to utilize existing photolithography equipment to pattern QD layers, resulting in a faster time to market and lower capex compared to IJP. Some of the processing steps are harsh on QDs though, which could be why this display appeared dimmer than the others.

Figure from Sharp’s paper 20-3 “Characteristics of Cadmium-free Blue NanoLEDs with Protection Technology Applied to Quantum Dots” SID Display Week 2024.

The fact that there were three companies showing demos, and four companies talking seriously about commercialization signals to me that there could be a shift coming in the next few years with respect to advanced display tech. I am a strong believer that there will be a home for many different display technologies (OLED, uLED, LCD, etc) in the foreseeable future as each brings a unique advantage Soon we may need to add EL-QLED to this list. For the past 7 years I have been saying that EL-QLED is “3+ years” away from commercial products. Perhaps I will need to revise my estimate to a more concrete number.

Peter Palomaki is the owner and chief scientist at Palomaki Consulting. He is widely recognized for his display teardown videos and scientific approach to helping clients. He utilizes his expertise in quantum dots and materials chemistry to solve challenging problems with clients large and small.