This new material could have significant implications for the development of high-performance, solution-processed OLEDs, particularly for use in flexible and wearable electronics.

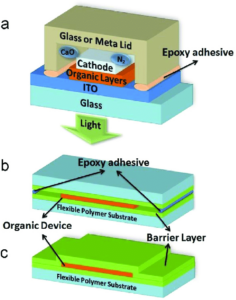

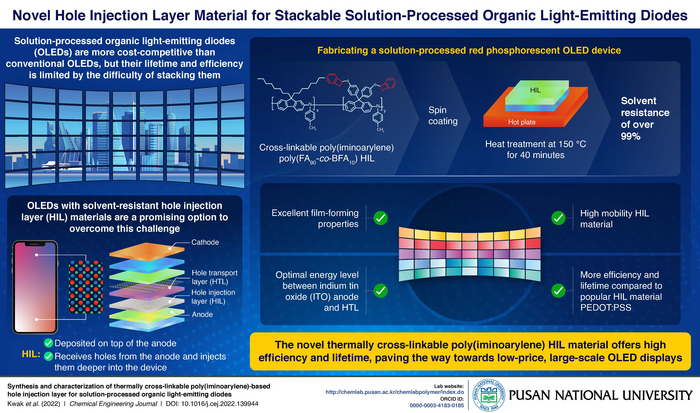

A new research paper funded by the South Korean government and appearing in the Chemical Engineering Journal explores the development of a cross-linkable poly(iminoarylene)-based hole injection layer (HIL) for organic light-emitting diode (OLED) displays. One of the major challenges in making OLED displays is the fabrication of multi-layered thin films created through vacuum deposition. These thin films consist of different layers with specific functions, such as the emissive layer, the hole injection layer, and the electron injection layer. These layers need to be deposited sequentially, with each layer carefully designed and optimized to achieve the desired device performance. However, the vacuum deposition process is time-consuming, expensive, and not suitable for large-area production.

One approach to address this challenge is to use a solution-based process, which is more cost-effective and can be used for large-area production. However, this approach also has its own challenges. For example, when preparing a solution-processed OLED device, the solvent used to form the upper layer can damage the lower layer, resulting in reduced device efficiency and lifetime.

The definition of a solvent is a substance that can dissolve other substances, typically a liquid. In the context of OLED manufacturing, a solvent is used to dissolve the organic materials that make up the various layers of the device. However, the solvent needs to be carefully chosen to avoid damaging the underlying layers. One way to address this challenge is to use orthogonal solvents, which are solvents that do not mix with each other and can be used to form the upper and lower layers without damaging each other. Another approach is to chemically crosslink the lower layer to improve solvent resistance, which can be achieved by heating or irradiating the material to form strong bonds between the polymer chains.

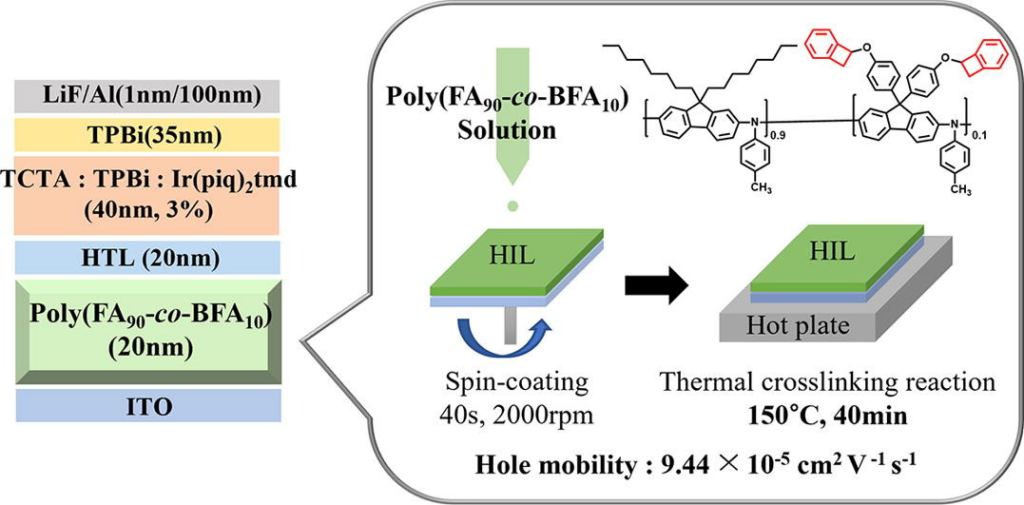

The researchers in this study synthesized a novel cross-linkable poly(iminoarylene) material, poly[(9,9-dioctyl-N-(p-tolyl)-9H-fluoren-2-amine)–co-(9,9-bis(4-(bicyclo[4.2.0]octa-1(6),2,4-trien-7-yloxy)phenyl)-N-(p-tolyl)-9H-fluoren-2-amine)] [poly(FA-co-BFA)], for use as a HIL. The material contains a thermally curable functional group, benzocyclobutene (BCB), which allows for complete crosslinking of the film without the need for additional initiators. The researchers used a range of materials, including 9-fluorene, bromine, tetrabutylammonium bromide, benzocyclobutene, and more, purchased from various companies and used without further purification.

To test the performance of the new HIL, the researchers fabricated a solution-processed red phosphorescent OLED device using a photo-crosslinked poly[bis(4-butypheny)-bis(phenyl)benzidine] (poly-TPD) as the hole-transporting layer (HTL). The resulting device showed a low turn-on voltage (Von) of 3.5 V, a current efficiency (CE) of 16.6 cd/A, and an external quantum efficiency (EQE) of 12.5%, outperforming a reference device that used PEDOT:PSS as the HIL. Additionally, the device fabricated using poly(FA-co-BFA) demonstrated a longer lifetime than the reference device.

Reference

Lee Kwak, S., Jung Park, H., Jang, J.-H., Yong Park, J., Mok Park, J., Lee, J., & Hwang, D.-H. (2023). Synthesis and characterization of thermally cross-linkable poly(iminoarylene)-based hole injection layer for solution-processed organic light-emitting diodes. Chemical Engineering Journal, 454, 139944. https://doi.org/10.1016/j.cej.2022.139944