No, this is not a question of cosmic proportions. I’m not, for example, asking how we should tackle the current Covid 19 pandemic. Rather, I’m asking a much narrower display-related question.

Last week Bob Raikes reported on Samsung Display Company’s (SDC’s) announcement that it would cease all LCD manufacturing by the end of this year (Another of Those Damned Inflection Points….). SDC had not been keeping its intentions at all secret, but previous announcements suggested the LCD end time would be in the 2021-22 time frame. Instead, its happening NOW.

Yesterday, a client asked me if this means Samsung will stop making LCD TVs. The question surprised me, but it deserves an answer. The answer is no. Samsung Electronics will continue to make LCD TV sets, both with and without quantum dots, but they will be buying the panels from Chinese suppliers, not SDC.

So here’s my question: What will SDC do now? And the answer: Quantum Dot OLED (QD-OLED). Most of what follows isn’t new but SDC’s announcement will reshape the display industry, and that calls for wrapping some context around the announcement.

Most readers of this column know display makers can produce many more LCDs than their customers want to buy, and profit margins are dropping below zero. Several Gen 10.5 fabs have been built in China, with more having been put on hold. When new capacity does comes on line, it will come on line in China. Making LCDs in Korea will never again be a winning proposition. (I know. Never say “never,” but….)

On the other hand, demand for TV-sized OLED panels is on the increase, with encouraging projections for the future. All OLED panels for consumer television are made by one company, SDC’s arch-rival LG Display. This is where SDC decided to go (again – Editor). SDC dominates the market for smartphone OLED panels, but the technology it uses is not practical for TV-sized panels, and SDC can’t use LGD’s proprietary color-by-white technology. In LGD’s technology (acquired from Kodak), an unpatterned white OLED emitter (which is a mixture of red, green, and blue emitters) is coated on the substrate, with the sub-pixel locations defined by the TFT pixel switches. An LCD-style matrix color filter gives each sub-pixel its appropriate color.

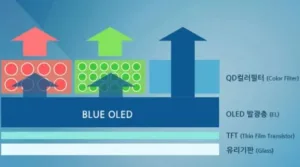

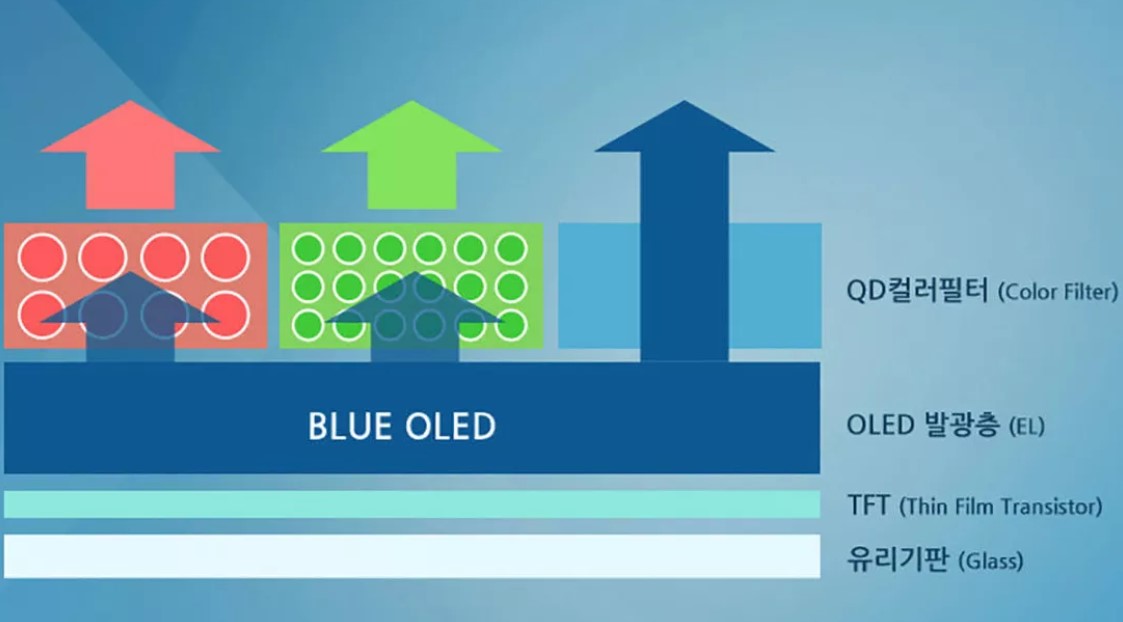

This highly simplified diagram shows that in SDC’s QD-OLED architecture, patterned quantum dots substitute for the matrix color filter used in LCDs and in LGDs “color-by-white” OLED displays. (Diagram: SDC)

This highly simplified diagram shows that in SDC’s QD-OLED architecture, patterned quantum dots substitute for the matrix color filter used in LCDs and in LGDs “color-by-white” OLED displays. (Diagram: SDC)

SDC is coating its substrate with an unpatterned blue OLED emitter. Actually, it’s three separate layers, with each layer perhaps emitting at a slightly different wavelength. As with LGD, the subpixel locations are defined by the TFT pixel switches. Now, things get even more interesting. Instead of a color filter, SDC uses a color filter replacement composed of a pattern of quantum dots. The areas of “red” quantum dots convert the blue light from red-subpixels to red, and similarly with the areas of “green” quantum dots. The areas corresponding to blue subpixels are simply clear diffusive areas. This is what SDC calls QD-OLED.

Since it is not yet possible for the quantum-dot areas to convert 100 percent of the incoming blue light, the blue light that makes its way through the red and green areas must be blocked by an extra filter, which also serves to block ambient blue light from exciting the quantum dots.

This is not a simple system, but SDC is betting well in excess of $10 billion on its success despite well-known technical problems with its approach. Clearly SDC thinks it has solved those problems. Thanks to the company’s announcement, we will soon be able to see for ourselves. (KW)

Ken Werner is Principal of Nutmeg Consultants, specializing in the display industry, manufacturing, technology, and applications, including mobile devices, automotive, and television. He consults for attorneys, investment analysts, and companies re-positioning themselves within the display industry or using displays in their products. He is the 2017 recipient of the Society for Information Display’s Lewis and Beatrice Winner Award. You can reach him at [email protected] or www.nutmegconsultants.com.