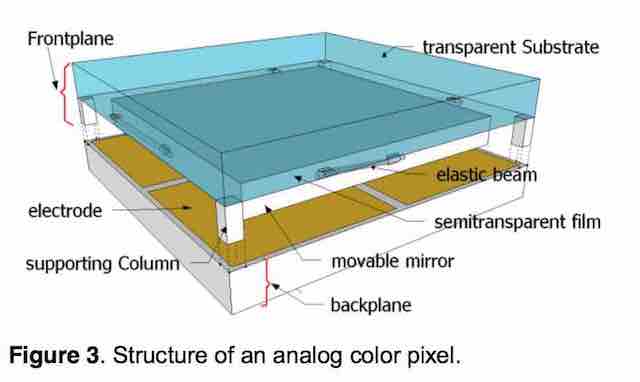

In what was undoubtedly the “hardest sell” at the recent SID Display Week, we found a resurrected Interferometric (Mirasol-like) single pixel prototype featuring a high bright color saturated, tunable pixel lit entirely by reflected light. Unlike the ill-fated Mirasol, this analog pixel is fabricated not by a MEMS process, but rather a “low cost additive process” that can produce a display using virtually no power to maintain its color image.

What was shown was a millimetre-sized, tunable interferometric color pixel that reflects “fully saturated colors over the entire visible spectrum,” according to Dr Zhong Ji, a mechanical engineer who told us he took a “tabula rasa” approach to reflective color displays that resulted in his large reflective color pixel, shown in the 2017 Display Week iZone.

Dr. Ji, CEO of China-based Hangzhou Yuansetech Ltd said his initial target market for this rather large analog pixel is outdoor displays signage with benefits (beyond high color saturation in a reflective display) that include a no power on state, very low power to change the display image, high color visibility in ambient sunlight, and low manufacturing costs. So what’s the catch? Four letters, IMOD (interferometric modulator display) that spelled doom to the Qualcomm display initiative bottom line to the tune of + $1B.

Yuansetech’s millimeter sized analog reflective color pixel using non-MEMS processing, Source company The logic goes, if the brilliant folks over at Qualcomm who spent nine figures (count em nine zero’s) on a display technology, and couldn’t make it work, what hope does a sole mechanical engineer have at success? And I was told by Dr Ji (and his wife companion at the booth) there were many at the show who took time to view the technology and immediately dismissed it as a re-hash of Qualcomm’s IMOD billion dollar boondoggle.

Yuansetech’s millimeter sized analog reflective color pixel using non-MEMS processing, Source company The logic goes, if the brilliant folks over at Qualcomm who spent nine figures (count em nine zero’s) on a display technology, and couldn’t make it work, what hope does a sole mechanical engineer have at success? And I was told by Dr Ji (and his wife companion at the booth) there were many at the show who took time to view the technology and immediately dismissed it as a re-hash of Qualcomm’s IMOD billion dollar boondoggle.

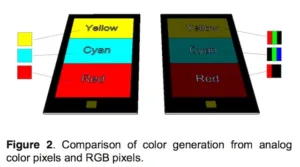

Yuansetech uses hue saturation lightness (HSL) to achieve high color saturation in its 4mm x 4mm pixel, source: company

To the critics, Ji will gladly offer his solution which is intended to avoid repeating the mistakes of the past. Specifically, he said the unique micro-assembly method overcomes the limitations of traditional MEMS photolithography. It’s low cost and a semiconductor packaging approach can be adapted to assemble the low resolution pixel array, and keeps large interferometric surfaces parallel with optical precision for high color purity and reflectivity.

Keep in mind that existing outdoor applications such as billboards can display either a fixed printed image or use power hungry LED arrays, with presently, no good alternative electronic display solutions. Zhong asserts large pixel reflective color displays are ideal for billboards and will “…fill the void between fixed printed images and LED arrays,” he said.

Live color images can be displayed while consuming significantly less power than LED arrays. The low power features of a large pixel RCD array also open the door for wireless display capabilities powered by a solar panel and updated by low power wireless sensor networks. It is especially valuable in locations where utility power is difficult and costly to provide.

So in this summer of 2017, and the prelude to Infocomm in Orlando, with its big outdoor displays, one might well ask, why we are not better leveraging the power of the sun to help information displays do what they do best – that is dynamically informing and entertaining? Stephen Sechrist