Researchers from the Korea Institute of Science and Technology (KIST) and Seoul National University have developed a stretchable substrate that achieves transparency and distortion-free performance, addressing critical challenges in flexible displays and wearable devices.

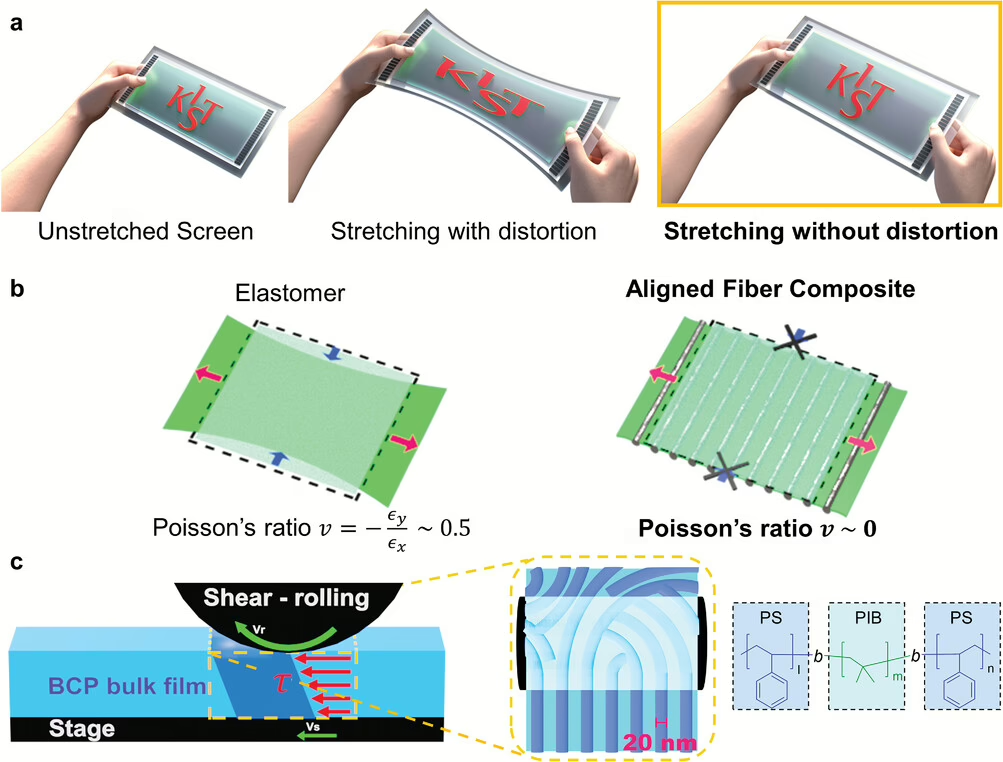

The team tackled a key limitation in existing stretchable materials: the Poisson’s ratio phenomenon. This effect, which causes horizontal contraction when a material is stretched, often results in image distortion and discomfort in wearable applications. By reducing the Poisson’s ratio to near zero—down to 0.07 in some cases—the researchers minimized vertical contraction, achieving uniform strain distribution while maintaining optical clarity. However, achieving this significant reduction in the Poisson’s ratio required specific conditions, particularly the precise alignment of nanostructures through a high-temperature shear-rolling process. Without this method, typical elastomers still exhibit Poisson’s ratios between 0.4 and 0.5.

Here’s how the researchers’ approach combined two key methods. In the first place, they used block copolymer alignment by employing a material composed of rigid polystyrene (PS) and flexible polyisobutylene (PIB). Through a process of unidirectional alignment of cylindrical nanostructures within the material, they achieved mechanical anisotropy. This property, which creates a significant difference in stiffness between the stretching direction and the perpendicular direction, reduced the Poisson’s ratio and ensured minimal distortion during stretching. Secondly, they applied a shear-rolling process to align the nanostructures uniformly across the entire substrate. By creating a velocity difference between a roller and a stage at high temperatures, the process achieved consistent alignment even in thicker films, measuring up to 0.7 mm. This method not only enhanced mechanical performance but also preserved the substrate’s high transparency, maintaining over 84% clarity even under strain.

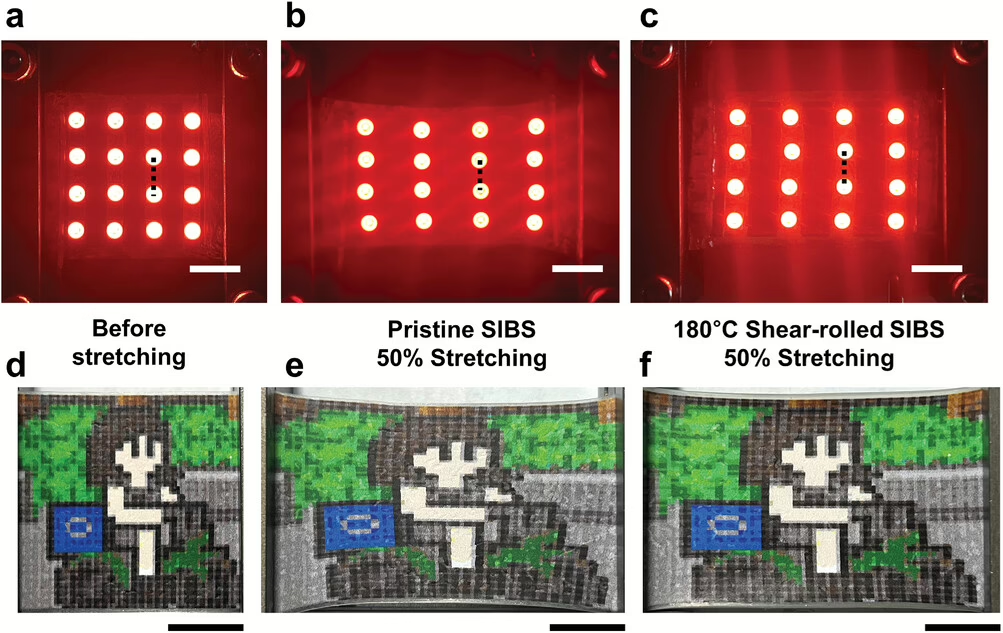

The team conducted extensive experiments to validate their findings. Stress-strain tests demonstrated significant improvements in mechanical anisotropy, with the aligned nanostructures providing up to a fivefold increase in elastic modulus along the alignment direction compared to the perpendicular direction. Transparency tests confirmed that the substrate retained optical clarity, free of haze or surface irregularities, even after 50% elongation. Tests on stretchable devices further highlighted the material’s performance. When applied to MiniLED displays and printed substrates, the material preserved pixel alignment and clarity, in stark contrast to conventional elastomers, which exhibited significant pixel distortion and contraction when stretched.

The potential applications for this substrate are numerous. Its ability to maintain transparency and prevent image distortion makes it suitable for next-generation displays, wearable electronics, and energy devices such as solar cells. The scalability of the shear-rolling process also suggests its applicability to other polymer systems, allowing for the mass production of high-performance substrates.

Despite its promise, the technology presents certain challenges. The researchers admit that the scalability and integration of the shear-rolling process into existing manufacturing systems require further exploration, particularly in managing film delamination and ensuring precise temperature control during processing. While the Poisson’s ratio can be reduced to near zero, this is contingent on maintaining optimal alignment and conditions during processing. Addressing these challenges will be essential for the broader industrial application of this technology.

Reference

J. Hur, H. Park, H. Oh, S. Jeong, J. Cho, J. Lee, S. Chung, Y. Hong, J. G. Son, Fully Transparent and Distortion-Free Monotonically Stretchable Substrate by Nanostructure Alignment. Adv. Mater. 2024, 2414794. https://doi.org/10.1002/adma.202414794