Smartkem announced its first sale of Trueflex semiconductor materials to its co-development partner, Shanghai Chip Foundation Semiconductor Technology Co., Ltd. (Chip Foundation). This sale marks the beginning of a collaboration aimed at developing next-generation MicroLED-based backlight technologies for Liquid Crystal Displays (LCDs). The agreement signifies a milestone in establishing the commercial viability of Smartkem’s organic thin-film transistor (OTFT) materials in display technology.

Smartkem is supplying its proprietary organic dielectric material, the Redistribution Layer (RDL), to integrate with Chip Foundation’s MicroLED devices. This joint effort seeks to create high-performance backlight solutions characterized by high brightness, improved current efficiency, reduced power loss, and enhanced illumination uniformity. Additional sales under the co-development agreement are expected to continue throughout 2025.

Chip Foundation, known for its substrate technologies, brings expertise in Chemical Lift-off (CLO) processes and Dielectric Patterned Sapphire Substrates (DPSS), which address critical challenges in MicroLED manufacturing. These include reducing dislocation density and enhancing the reliability and heat dissipation of GaN-based devices.

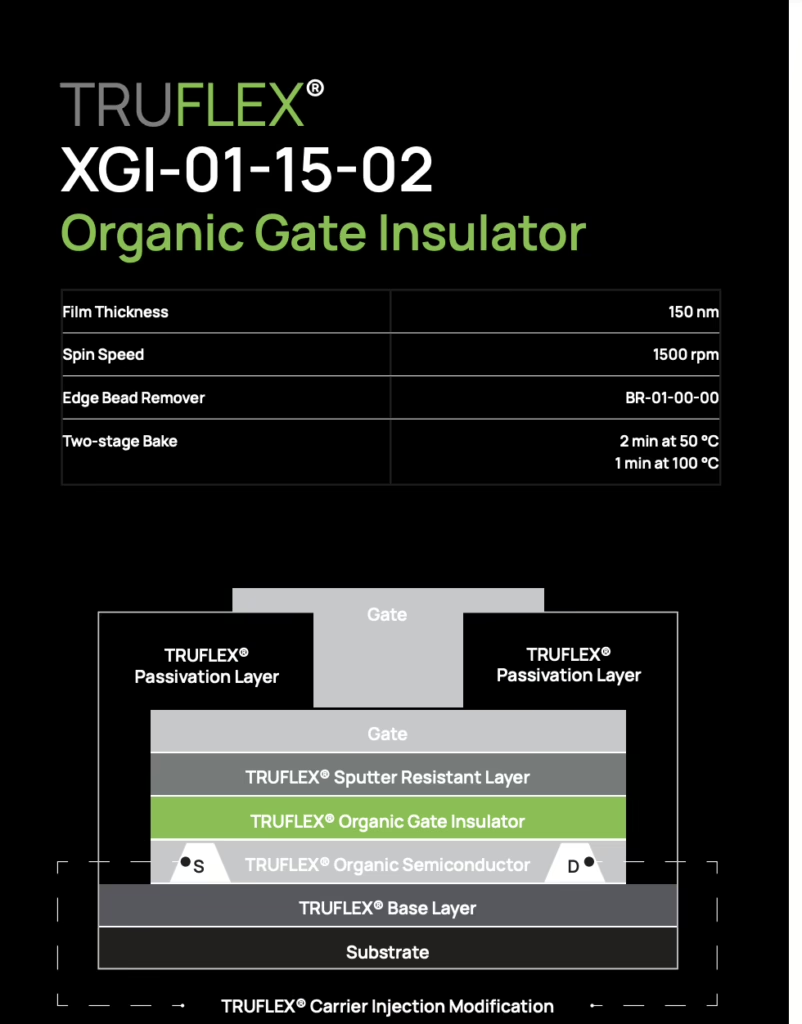

Smartkem is leveraging its proprietary semiconductor ink technology to enable advancements in display manufacturing. Its materials, such as organic thin-film transistors (OTFTs), are built using a stack of solution-processed layers, including organic semiconductors, gate insulators, and passivation layers. These materials offer the unique ability to be processed at temperatures as low as 80°C, significantly lower than traditional methods, which often require over 300°C. This low-temperature process allows compatibility with existing manufacturing infrastructure, reducing energy consumption and costs.

The Trueflex platform supports various display technologies, including MicroLED, MiniLED, and AMOLED. The organic semiconductors are formulated to create high-mobility, hole-transporting layers, while gate insulators and passivation layers are designed to provide stability, reliability, and protection against environmental factors. The single-layer organic materials are compatible with industry-standard substrates such as plastics, glass, and flexible films, further expanding their utility.