Researchers at the School of Engineering of the Hong Kong University of Science and Technology (HKUST), in collaboration with the Southern University of Science and Technology and the Suzhou Institute of Nanotechnology of the Chinese Academy of Sciences, have developed a deep-ultraviolet (UVC) MicroLED display array for lithography machines. This development aims to lower the cost of maskless photolithography by providing sufficient light output power density to expose photoresist films more efficiently.

The project addresses challenges in conventional lithography machines, which rely on short-wavelength ultraviolet light to fabricate integrated circuits. Current mercury lamps and deep ultraviolet LED light sources often have drawbacks such as large device size, lower resolution, high energy consumption, and inadequate optical power density.

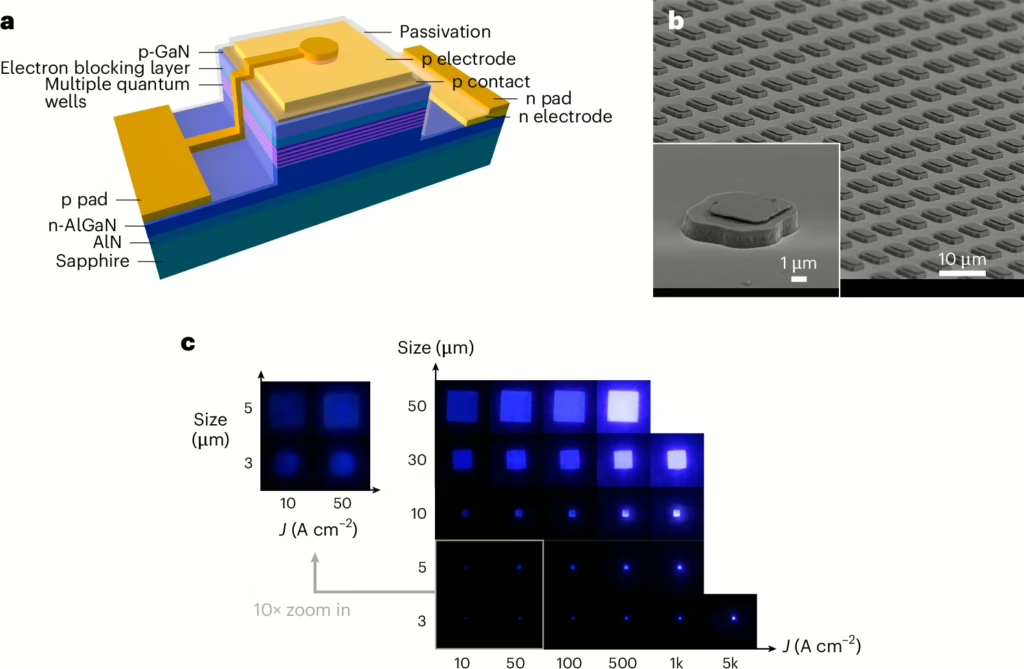

To address these limitations, the research team built a maskless lithography prototype platform and used it to fabricate a MicroLED device with improved optical extraction efficiency, heat distribution performance, and epitaxial stress relief. The device’s deep-UV MicroLED display chip combines the ultraviolet light source with a mask pattern, delivering sufficient irradiation dose for photoresist exposure in a shorter time.

The maskless lithography offers benefits including real-time pattern adjustment, multiple customization options, and reduced costs associated with lithography masks. By integrating a short-wavelength MicroLED technology, the team’s work supports the advancement of semiconductor equipment.

Future work will involve further enhancing the performance of AlGaN deep ultraviolet MicroLEDs, refining the prototype, and developing 2k to 8k high-resolution deep ultraviolet MicroLED display screens.

Reference

Feng, F., Liu, Y., Zhang, K. et al. High-power AlGaN deep-ultraviolet micro-light-emitting diode displays for maskless photolithography. Nat. Photon. (2024). https://doi.org/10.1038/s41566-024-01551-7