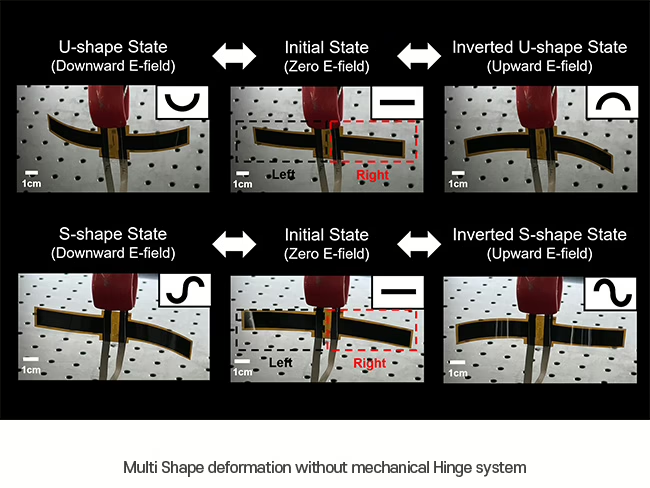

Researchers have introduced a fully mechanically-free display technology. Unlike conventional flexible displays, which rely on mechanical components such as hinges or sliders to enable shape changes, this new technology achieves shape control without any mechanical parts at all.

At the core is OLED technology. OLED displays are composed of thin layers of organic compounds situated between two conductive layers, typically a transparent anode and a metallic cathode. When an electrical current passes through these organic layers, they emit light, thus creating images without the need for an external backlight. Because OLED displays generate their own illumination, they can be constructed much thinner and lighter compared to traditional LCD screens, which require backlighting.

The absence of mechanical components emphasizes OLED’s intrinsic advantages, allowing the display panel to flex, bend, and adopt various shapes more freely. The researchers have specifically demonstrated this capability on smartphone-scale panels, showcasing displays that can dynamically and reversibly transform into different shapes. The reversible aspect is particularly important because it means the panel can continuously change forms without degradation or damage. Such shape adaptability is made possible because OLED’s organic materials and conductive layers can tolerate considerable mechanical deformation without compromising their functionality.

One aspect of OLED’s flexibility is that the materials involved, including the organic emissive layers and electrodes, can maintain their electrical and optical performance even when repeatedly bent or curved. By removing mechanical elements completely, researchers have reduced overall device weight and complexity.

The demonstrations of this new mechanically-free technology specifically targeted smartphone-sized screens. This represents the most common form factor in consumer electronics. Smartphones require durable yet flexible screens capable of repeated shape transformations.

Beyond smartphones, researchers suggest substantial opportunities for broader applications. In the automotive industry, this flexibility could enable displays to fit seamlessly into the contours of vehicle interiors. Automotive displays often face constraints due to rigid flat panels, but flexible OLED screens can conform to dashboards or other interior surfaces without compromising image quality or usability.

The technology also holds promise for soft robotic interfaces, an emerging field where flexible and adaptive materials are crucial. Soft robots, which interact safely and effectively with human users, could integrate these mechanically-free OLED screens into their bodies or limbs, enhancing their ability to visually communicate or dynamically adjust their physical forms in response to environmental interactions or user needs.

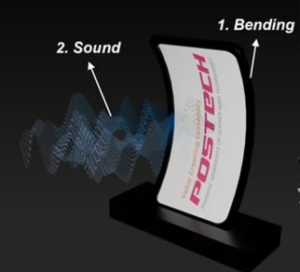

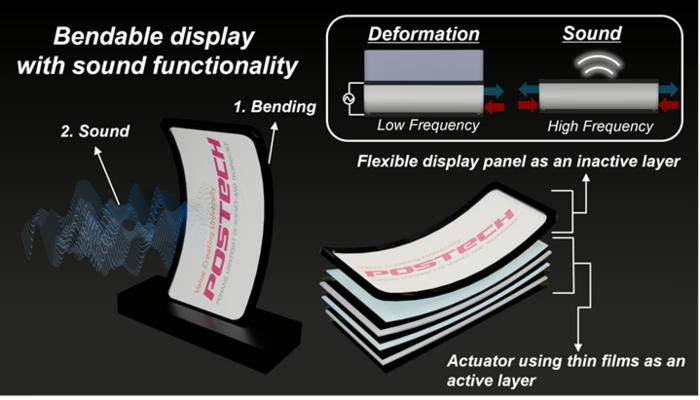

The sound in this mechanically-free OLED panel is generated through the vibration of a thin film made from poly(vinylidene fluoride), or PVDF, an electroactive polymer that acts as a piezoelectric actuator. Piezoelectric materials convert electrical signals directly into mechanical motion (vibrations, in this case) which produce sound waves.

The PVDF film serves as the active component of the actuator. When electrical signals are applied, the PVDF rapidly changes shape, expanding or contracting, due to the piezoelectric effect. This rapid motion occurs at frequencies that range into the audible spectrum, allowing it to generate sound waves.

Instead of relying on traditional speaker components, the OLED screen’s natural thinness and flexibility allow it to act effectively as a speaker diaphragm. Low-frequency signals enable slow, controlled shape deformation of the OLED screen, creating dynamic visual effects. High-frequency signals, meanwhile, drive rapid vibrations that produce audible sound.

Reference

Park, J. Y., Shin, J. H., Hong, I. P., Nam, S., Han, S. H., & Choi, S. S. (2025). Dynamic bendable display with sound integration using asymmetric strain control of actuators with flexible OLED. Npj Flexible Electronics, 9(1), 1–11. https://doi.org/10.1038/s41528-025-00396-6