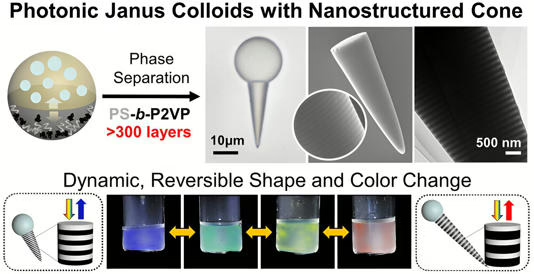

Researchers at UNIST in Korea, led by Professor Kang Hee Ku, have developed a breakthrough method for creating diblock copolymer (dBCP) particles with more than 300 perfectly ordered photonic layers. Unlike traditional approaches requiring intricate external templating, this self-assembly process relies on the spontaneous separation of silicone oil from polystyrene-block-poly(2-vinylpyridine) (PS-b-P2VP) as a solvent evaporates, forming Janus-type particles. On one side, an oil droplet remains, while on the other side, a cone-shaped polymer framework houses layers of lamellae aligned along its axis—an arrangement responsible for the vivid, tunable structural colors.

The shape and color of these ice cream cone particles can be fine-tuned by adjusting the ratio of silicone oil to polymer as well as by selecting different molecular weights. Once formed, they respond dynamically to changes in their surroundings (for instance, variations in pH or alcohol concentration) by reversibly swelling or contracting. These shifts alter the spacing within the lamellar layers, producing visible color changes in real time. Because the color stems from nanoscale structures rather than pigments or dyes, it is generally brighter and more durable.

This approach also facilitates large-area color-patterning, demonstrated by the creation of RGB pixel arrays. The same technology could ultimately lead to advanced displays, sensors, paints, or coatings that offer vivid, adaptable colors without the need for complex external control systems.

Reference

Lee, J., Ban, S., Jo, K., Oh, H. S., Cho, J., & Ku, K. H. (2024). Dynamic Photonic Janus Colloids with Axially Stacked Structural Layers. ACS Nano, 18(6), 5196–5205. https://doi.org/10.1021/acsnano.4c00230