A team of researchers headed by Dong Chan Kim of the Center for Nanoparticle Research, Institute for Basic Science (Seoul, Korea) is developing a new technology to enable the production of foldable quantum dot light emitting diode (QLED) displays. Using the new technology, a passively driven QLED display can be folded into almost any predetermined shape.

Stated more generally, the researchers are developing flexible light emitting devices that can transform from a two dimensional form into a three dimensional form. The new technology has the potential to make possible the presentation of information that is difficult to implement with conventional, flat panel displays. Examples of applications in which the new technology could be useful include customizable portable displays such as electronic newspapers and tablet PCs.

During the past few years, various approaches have been investigated for converting two dimensional displays into three dimensional displays. One of these approaches is an origami-like method based on adding folding lines into the structure of an already flexible display. Unfortunately, the fabrication of foldable three dimensional light emitting devices by this means remains challenging due, in part, to the lack of a practical method for patterning the folding lines.

Addressing this issue was the focus of the research conducted by the team. A recent article on the topic by the team is entitled “Three-dimensional foldable quantum dot light-emitting diodes.” It was published in Nature Electronics volume 4, pages 671 – 680 (2021). A copy of the article is available for purchase and can be found here.

The process developed by the team was based on using a power controlled, pulsed CO2 laser to selectively etch a silver and aluminum alloy etch-stop layer that was deposited on top of an epoxy thin film which, in turn, was deposited on top of an ultra-thin (3 micron) QLED device. The advantage of this approach is that the depth of the etching can be precisely controlled. This was accomplished by adjusting the power of the laser and further tuned by the choice of the alloy used in the etch-stop layer. By these means, it was assured that laser etching process did not damage the underlying QLED device. In addition, mechanical simulation was used to engineer the device such that the strain associated with folding was minimized on the light emitting components.

After etching, the thickness of the surface under the etch lines was thinner than the surface in surrounding areas. As a result, when an external force was applied to deform the surface, the surface folded along the etch lines.

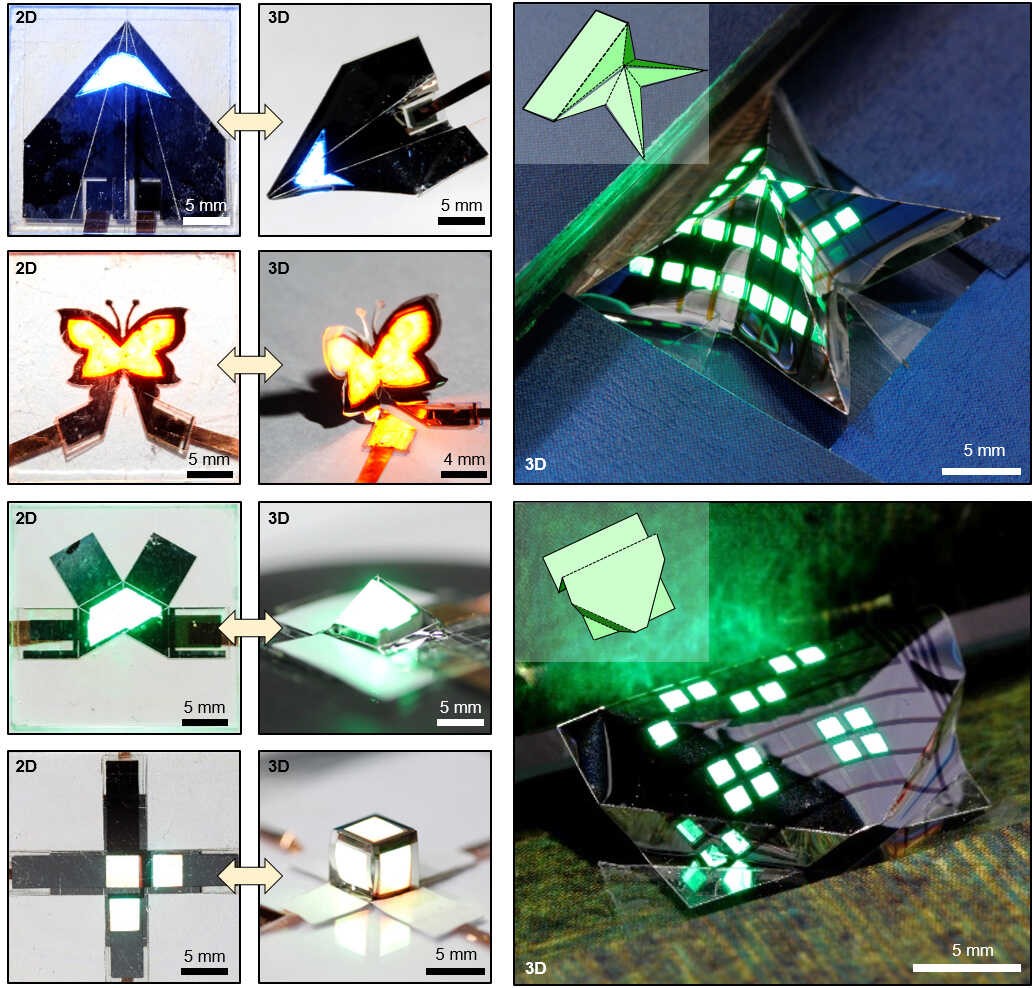

Utilizing the new etching process, the research team fabricated several prototype foldable three dimensional QLEDs having complex shapes as illustrated in the figure below.

Prototype QLED displays that can fold into predetermined shapes. Examples include a butterfly, a pyramid and a paper airplane. The shape can also transform from two dimensional to three dimensional.

Prototype QLED displays that can fold into predetermined shapes. Examples include a butterfly, a pyramid and a paper airplane. The shape can also transform from two dimensional to three dimensional.

Prototypes fabricated by the research team demonstrated the capability to precisely control the radius of curvature of the foldable QLED. In fact, the team successfully fabricated a foldable QLED with a very small radius of curvature, less than about 50 microns. In their article, the researchers commented that, when the radius of curvature becomes smaller than several tens of microns, it appears to the naked eye to be sharply folded rather than bent. The researchers also reported that “all light emitting surfaces including corners were stably driven even after being folded over 500 times.”

Despite all of the accomplishments reported by the team, it is clear that this technology is still in an early stage of development. The first reason is that the prototype displays produced using the new technology had an extremely low resolution, about 64 pixels. The second reason is that, although the QLED display could be folded over 500 times without performance degradation, this pales in comparison to the durability demonstrated by the current generation of foldable displays. The durability of current commercial foldable displays can be put into proper context by noting that Samsung has stated that the company’s Galaxy Fold device folds and unfolds 200,000 times without performance loss.

The researchers conclude their article with forward looking statements: that the display resolution can be increased and that “in the future, we will be able to produce QLED displays with more complex form factors.” -Arthur Berman

Seoul National University, Taeghwan Hyeon, [email protected]