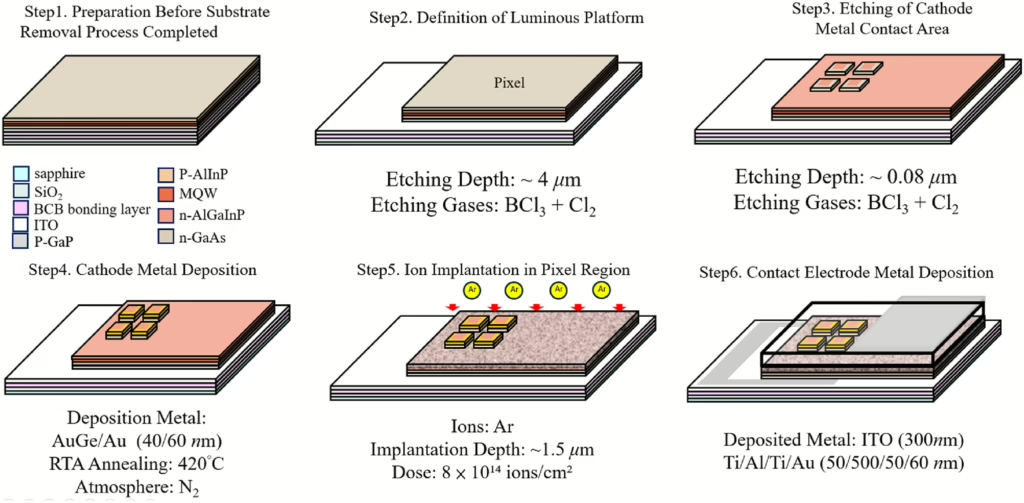

New research provides a detailed analysis of how ion implantation impacts the performance of AlGaInP red MicroLEDs. MicroLEDs, which are gaining attention for their potential in display and optoelectronic applications, require precise fabrication techniques to ensure efficiency and reliability, especially as devices shrink in size. Traditional fabrication methods, such as dry etching, often introduce physical damage to the material and necessitate additional restorative steps. To address these challenges, the study explores ion implantation as a non-contact method for modifying the material’s properties with high precision.

The researchers used both experimental methods and simulations, specifically employing the Stopping and Range of Ions in Matter (SRIM) software, to examine the behavior of ions implanted into the MicroLED material. This simulation allowed the team to predict ion trajectories, energy loss, and the resulting vacancies—structural disruptions that play a role in modifying the material’s properties. The study compared single-energy implantation, where ions are implanted at a fixed energy level, to progressive-energy implantation, which introduces ions at multiple energy levels. The latter approach demonstrated better performance by achieving a more uniform distribution of ions and a more effective insulation layer.

Three types of ions—argon (Ar), fluorine (F), and arsenic (As)—were evaluated at comparable doses to understand their distinct effects on the MicroLEDs’ electrical and optical properties. Among these, As ions showed superior results in improving device performance. The high atomic mass of As resulted in a greater number of vacancies, which enhanced insulation by minimizing leakage current and optimizing the distribution of the electric field within the material. This improvement in insulation properties contributed directly to the reduction of leakage currents and enhanced external quantum efficiency (EQE). EQE is a key metric that measures how effectively a device converts electrical energy into emitted light, making it a critical factor for evaluating MicroLED performance.

The study also explored the effects of implantation energy. For single-energy implantation, 50 keV was identified as the optimal energy level, providing a balance between effective insulation and maintaining sufficient electrical conductivity. When the implantation energy was too high, ions penetrated too deeply, creating overly thick insulation layers that impeded electrical performance. Conversely, lower energy levels resulted in insufficient insulation. Progressive-energy implantation addressed these limitations by incrementally varying the energy levels, achieving a balanced ion distribution that improved both insulation and electrical conductivity.

Another significant finding was the comparison of ion types. Devices implanted with lighter ions, such as F, generated fewer vacancies, resulting in less effective insulation and higher leakage currents. In contrast, devices treated with As ions not only exhibited lower leakage currents but also maintained higher optical output power. This enhancement was attributed to the increased number of vacancies produced by As ions, which facilitated radiative recombination—the process by which electrons and holes recombine to emit photons, the basis of light emission in LEDs.

The researchers analyzed the effects of ion implantation on light emission intensity and optical efficiency. MicroLEDs treated with As ions showed the highest light output intensity and EQE, even at high input currents. The improved insulation and uniform electric field distribution provided by As ions enabled better carrier mobility, ensuring efficient charge transport and minimizing losses.

Ion implantation, particularly with As ions and progressive-energy techniques, seems to be a powerful tool for optimizing the performance of AlGaInP MicroLEDs. By achieving precise control over the depth and distribution of implanted ions, the researchers addressed key challenges in MicroLED fabrication, such as reducing leakage currents, improving insulation, and enhancing optical output efficiency.

Reference

Chiang, W.-H., Chen, Y.-R., Hsu, Y.-C., Lo, S.-J., Singh, A. K., Chou, H.-Y., Liu, P.-L., & Wuu, D.-S. (2025). Impact of ion implantation on the performance of AlGaInP Micro-LEDs. Materials Today Advances, 25, 100552. https://doi.org/10.1016/j.mtadv.2024.100552