OLED as an emissive display is at the forefront of next generation TV technology due to its superior performance compared to traditional backlight based LCD technology. But its adoption rate in the TV industry has been limited due to higher cost, low production volume and other challenges. LCD still has the dominant market share.

The mature TV market needs lower price, larger screen sizes, higher resolution and higher performance products to drive replacement demand. OLED display technology is evolving with new materials, new equipment and new solutions to reduce cost and increase adoption rates.

White OLED TV – Current leading solution

White OLED TV technology with RGB color filter is in production today with LG Display being the only panel supplier. This technology still uses an evaporation process (without shadow mask) which requires many layers deposited by vacuum thermal evaporation driving higher cost for both equipment and materials. It also has higher capex costs and material cost resulting in high manufacturing cost for large size TV. White OLED self emissive TV technology delivers super performance, vivid colors, higher contrast, a true black color, energy efficiency and a thinner flexible form factor. However, it also suffers from lifetime issues especially for blue emitter, peak brightness, higher cost and lower production volume.

LG Display has been the only supplier for white OLED. It has started working on RGB IJP (ink jet printing) technology and presented a paper at Display Week 2019 with Nanosys on ELQD. LGD recently announced that it will invest an additional 3 trillion KRW into a Gen 10.5 (2,940mm x 3370mm) OLED production line, mainly producing 65-inch and above super-size TV panels. It will start producing 30K sheets/m from the first half of 2022 and an additional 15K sheets/m will be produced from the first half of 2023. LGD will use the MMG (Multi Model on a glass) method where it will combine different sizes on one mother glass to improve profitability.

RGB OLED TV – Potential future wave

RGB OLED technology has been successfully produced and used for smartphone and other smaller size displays. But it has been a great challenge to produce RGB on larger glass for TV application. Also new OLED TV technology is needed to overcome the higher cost structure of white OLED. RGB OLED has a simple device structure leading to potentially lower cost. But large-scale manufacturing is still immature and IJP and OVJP (Organic Vapor Jet Printing) technology are still developing. Short material lifetimes and device challenges may still exist for this technology butRGB OLED may be the future wave. According to Applied Material’s presentation at DisplayWeek 2019,

“RGB OLED TV can achieve LCD cost parity and mass adoption with material improvement (ink jet) and/ or equipment innovations (evaporation)”.

RGB OLED TV – Inkjet printing (IJP) solution

Inkjet printing can have cost advantages compared to the VTE (Vacuum Thermal Evaporation) techniques currently used. According to Kateeva’s presentation at the Display Week 2019 Business Conference, the VTE process uses only 10% of source materials whereas inkjet printing uses 95% of the solution materials. Ink jet printing‘s additive manufacturing technique ensures material efficiency and allows for soft mask designs with fewer lithography and mask requirements. With more efficient use of RGB materials, and no color filter or shadow mask, IJP should be scalable to large glass sizes. It has the potential for producing higher brightness and lower cost TVs. Companies such as Kateeva can enable lower cost OLED TV production with ink jet printing for RGB pixel printing. Production of top emission OLED panels can facilitate the 8K revolution in OLED by increasing the optical performance. RGB OLED for IJP is still under development. It can provide many benefits for panel makers by reducing manufacturing cost, and enhancing OLED performance.

Ink Jet Printing (image:Kateeva)

Ink Jet Printing (image:Kateeva)

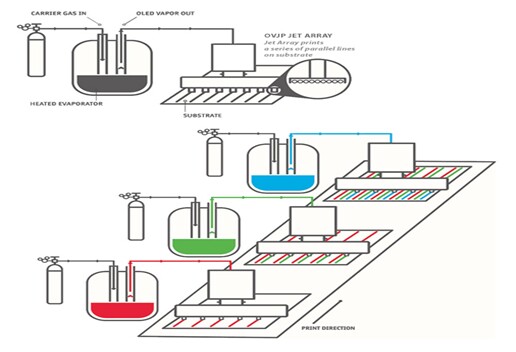

RGB OLED TV – Organic Vapor Jet Printing (OVJP) Solution

RGB OLED organic vapor jet printing is being developed as a mask-less, solvent-less printing technology for side-by-side RGB displays. According to Universal Display’s presentation at Display Week 2019, the emissive layers are dry printed using OVJP and there are no fine metal masks (FMM) and no solvent. Other layers can also be printed by OVJP or VTE. The OLED materials are the same as are currently used in standard VTE deposition. OVJP can be scaled to Gen 10 and beyond. Historically over-spray has been an issue with OVJP but new processes such as directed spray could eliminate or reduce these issues.

Organic Vapor Jet Printing (image:Universal Display Corp)

Organic Vapor Jet Printing (image:Universal Display Corp)

QD OLED TV – Quantum Dot Color Conversion Solution

Quantum dot (QD) technology can enable great increases in color gamut (supporting more of the BT 2020 gamut), higher brightness (4000 cd/m² and above) and purer colors by bringing LCD performance closer to OLED level. It can even exceed OLED in certain areas such as brightness. QDs are going from improving backlight of LCD to shifting to self-emissive display by eliminating backlight. Samsung Display is building a pilot production facility for QD OLED (with QD Color Convertor), which will start production in 2019. It simplifies the panel structure and fabrication process and eliminates shadow mask patterning. However the process needs highly efficient blue OLED materials with a long lifetime. This could open up new opportunities for QD. Blue OLED with a quantum dot color convertor layer should increase brightness efficiency, especially compared to the white OLED architecture used by LG Display. It can provide better material lifetime and lower costs due to the simpler structure. But the technology is not yet in mass production and it may still face issues in materials and Ink jet deposition.

Next Gen OLED TV – Needs new solution

OLED TV has secured a strong presence in the premium TV market because of great picture quality, design differentiation, perfect black and infinite contrast ratio. LG Electronics is the most successful brand using LG Display’s OLED TV panels. Other brands such as Sony, Panasonic, Skyworth, TPV, Hisense, Konka and others have joined in using LG Display’s panels. LGD is converting LCD TV capacity to OLED TV and accelerating its plans to develop 10.5G fab capacity. Ink jet printing (IJP) can offer lower manufacturing cost due to lower capex, lower material cost from the simple structure and color filter elimination. But the lifetime of soluble blue OLED needs improvement.

Summary

LG Display is increasing its 10.5 Gen OLED production capacity with additional investment. BOE, and CSOT are planning to bring in OLED capacity in future years. Many suppliers including Universal Display, Cynora, Kulux and others are working towards improving the efficiency, resolution, lifetime and costs of materials. Companies such as Applied Materials and Kateeva are developing new equipment for better cost and higher efficiency. LG Display is also working on RGB IJP (ink jet printing) technology and presented a paper at Displayweek 2019 with Nanosys. Samsung Display is building a pilot production facility for QD OLED (with QD Color Convertor).

New OLED TV technology solutions (RGB OLED, QD OLED,..) combined with printed manufacturing capabilities have the potential to enable lower-cost solutions and higher adoption rate. (SD)

Sweta Dash, President, Dash-Insights

Sweta Dash is the founding president of Dash-Insights, a market research and consulting company specializing in the display industry. For more information, contact [email protected] or visit www.dash-insight.com