A team of researchers headed by Professor Yoon Hong-seok within the Mechanical Engineering Department at the Hanbat National University (Daejeon Metropolitan City, Republic of Korea) are developing a new process to simultaneously transfer all of the multiple layers that make up an OLED film. The process uses the spray of high pressure gas and is represented as having the potential to reduce the manufacturing time of OLED and other, related, devices.

Previous transfer processes stripped the thin film layers composing an OLED from the substrate one at a time. As a result, a long time was required to transfer an OLED since the film could be composed of as many as 20 layers. In addition, previous transfer processes frequently damaged the thin film layers. As a result, such transfer processes were difficult to use in the high volume production of OLEDs.

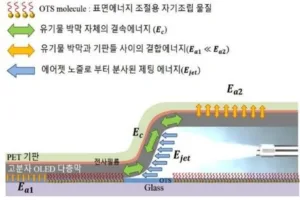

The new process uses an air jet technology that sprays a desquamating gas such as nitrogen, argon or air at high pressure. (From the Latin desquamare, desquamating is the shedding of the outermost membrane or layer of a tissue.) The gas is sprayed at a speed of 300 m/s between the OLED and the substrate. This process reduces the strength of the binding between the OLED and the substrate. At the same time, the process increases the binding energy of the organic layers that are to be transferred. These two effect together allow for the simultaneous transfer of multiple thin films. The process is illustrated in the figure below.

OLED transferring process using the spray of a high pressure gas.

Using the new air jet technology, thin films can be transferred quickly. The researchers speculate that the new process could reduce manufacturing time by as much as 90%. In addition, the new process is able to transfer films with little damage. One measure of the quality of the new transfer process is that thin films applied using the new method showed a surface roughness of 5.2 nanometers. This is a substantial reduction to the surface roughness of 47.3 nanometers found when thin films were applied with previous methods. -Arthur Berman

Hanbat National University, Yoon Hong-seok, [email protected], 042-821-1079