During the 2014 Printed Electronics Conference (Santa Clara, CA, November 18-20) Kateeva announced its YIELDjet FLEX manufacturing tool for flexible OLED displays. Kateeva offered attendees of Printed Electronics 2014 the opportunity to visit with Kateeva personnel and tour the firm’s facility in Menlo Park CA. During the Kateeva plant tour I had the opportunity to have lunch with Kateeva President and co-founder Conor Madigan and our guide for the Kateeva tour was CEO Alain Harrus.

Kateeva personnel were great hosts, providing lunch and freely answering our questions. During the tour we were shown Kateeva’s laboratories for OLED display development and fabrication, inkjet printing and materials development. We were also shown Kateeva’s Gen 8 capable YIELDjet printing tool. We were asked not to take photos during our tour so the photo of the Kateeva YIELDjet manufacturing tool (below) was provided by Kateeva.

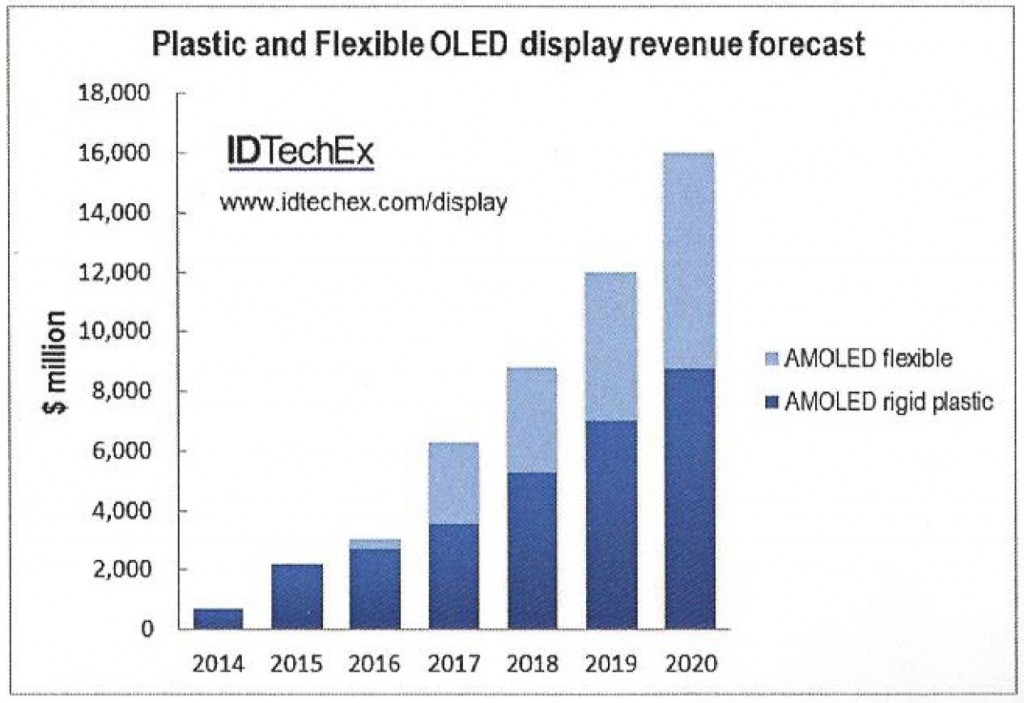

The YIELDjet FLEX manufacturing tool is the first product to be launched based on the Kateeva YIELDjet platform. Kateeva announced at the conference that the first system for mass production will ship later in November 2014 to a customer in Asia. The YIELDjet FLEX tool was developed to enable Thin Film Encapsulation (TFE) of flexible OLED displays. The market for flexible OLED displays is just now emerging although IDTEchEx presenter, Guillaume Chansin, forecast during Printed Electronics 2014 that the market for plastic and flexible OLED displays (graphic below) will grow to $16 billion by 2020 of which more than $8 billion is forecast for flexible displays in 2020.

During the session on Barrier Films and Encapsulation, Conor Madigan presented a talk entitled “Inkjet Technology for Mass Production Flexible Displays”. While Madigan also discussed inkjet printing of the OLED pixel materials, the primary subject of his presentation was inkjet printing of the thin film encapsulation (TFE) organic interlayer. Conor pointed out that the TFE organic layer is required to provide planarization and “defect decoupling” over the OLED display layer topology and any particulate matter present on the surface of the in-process display panel. He stated that a conformal coating will not serve this function and said that inkjet printing the “thick compliant organic layer pr380 cracks in the inorganic barrier layer from propagating through the structure”.

Concerning the various process alternatives for OLED display manufacturing, Madigan also stated that “evaporation through shadow masks is an evolutionary dead end, and that inkjet printing is “an ideal technology“ to replace evaporation. The inkjet-printed TFE layer planarizes and does not shrink on UV curing which would give rise to stress in the film, non-planarity and non-uniform shrinkage. Madigan described the attributes of the YIELDjet tool as providing ultralow particle contamination, a non-reactive nitrogen process environment, no chuck mura, fast recovery turnaround from maintenance, and enabling excellent film uniformity with a wide process window.

The YIELDjet FLEX manufacturing tool consists of the inkjet printer, with UV curing, nitrogen transfer and substrate buffering modules. The tool is capable of printing the 16 micron thick TFE film in 60 seconds for a Gen 8 panel yielding a mura-free, optically clear, flexible TFE layer with high adhesion and low outgassing. Madigan concluded his presentation stating that the YIELDjet printed “organic layer allows the inorganic TFE layers to deliver their real potential”. – Phil Wright