In the past, flexible and transparent displays have posed several challenges, such as poor transparency and low electrical performance. These types of displays are now in demand for wearables, augmented reality and the IoT. Inorganic electronics have been used, but the thermal instabilities of the plastic substrates have hampered the high temperature process necessary for fabrication.

The Korea Advanced Institute of Science and Technology (KAIST) has been working on a solution to the problem. A KAIST team has developed ultrathin and transparent oxide TFTs for the active matrix backplane of a flexible display. This was achieved using a method called inorganic-based laser list-off (ILLO).

The team fabricated a ‘high performance’ oxide TFT array on top of a sacrificial laser-reactive substrate. Lasers were fired at the rear of the substrate, irradiating it. After this, the TFTs were separated from the sacrificial layer, as a result of the reaction between the laser and substrate. They were then moved onto ultrathin (4µm) plastics. Finally, the transferred ultrathin oxide driving circuit for the flexible display was attached conformally to the surface of human skin. This was done to show how it could be used in wearable applications.

KAIST’s attached oxide TFTs showed optical transparency of 83% and mobility of 40 cm^2 V^(-1) s^(-1), even under several cycles of severe bending tests.

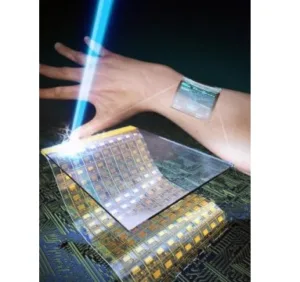

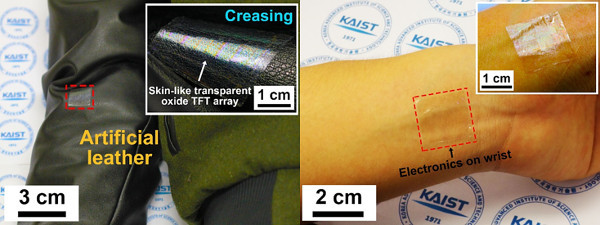

This picture shows ultrathin, flexible, and transparent oxide thin-film transistors attached to a jumper sleeve and human skin. (Source: KAIST)

This picture shows ultrathin, flexible, and transparent oxide thin-film transistors attached to a jumper sleeve and human skin. (Source: KAIST)