Etendue and brightness are two related terms that create never-ending thoughts and discussions. Recently, I re-read my previous article, “My Etendue Story”, and came up with new thoughts on how important light recycling is for LEDs and Laser Phosphor light sources used for projection systems. Here it goes.

Most if not all, handheld and portable projectors are powered by LEDs and the outputs are usually lower than desired. A darker than normal room is necessary for projecting the images with a reasonable size. The major issue is the brightness of the LED. They are simply not very bright as the output is limited by the current density, light conversion efficiency, junction temperature, and so on. In addition, the output angular distribution is too broad, lowering the coupling efficiency of the system, which is etendue related.

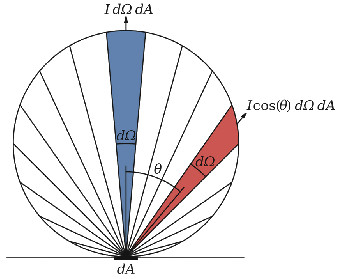

Most LEDs and Laser Phosphor light systems follow some kinds of Lambertian or “almost” Lambertian distributions that have either a “spherical”, “ellipsoidal”, or “somewhere-in-between” distributions. Simply speaking, the brightness along the optical axis is “brighter” than the brightness looking from the side at an angle.

In the optical on-axis and off-axis directions, the number of photons/sec directed into any wedge is proportional to the area of the wedge. This simply means that the on-axis intensity is higher than the off-axis intensity. If only the light output from a very small solid angle near the optical axis is collected, the brightness will be at its highest. If the light from a larger solid angle is collected, homogenized, and used for illuminating an imager, the average brightness will be lowered. The brightness continues to decrease as larger solid angles are used for collection. One of the main reason one uses a larger solid angle is simply to increase the overall lumen efficiency at the expense of brightness.

Projector designers routinely use larger LEDs with larger etendue for illuminating imagers with smaller etendue such that only the near on-axis outputs of the LEDs are collected. The rest of the LED outputs at larger angles will simply be discarded and not used. This is one area where light recycling vsn greatly improve the efficiency of the system as light recycling will put the discarded light back to the LED with part of the light being recycled and becoming useful output. Such improvement in output is considered to be the light recycling gain of the system.

Not all light recycling systems work the same way, as the etendue is the product of both the area and angle. As a result, light recycling can be done through area, angle, or both. As a matter of fact, light recycling is not very commonly used in projection systems. I believe the reason could be due to cost. On the other hand, I believe that the cost per screen lumen could be lower using light recycling.

Most of the projector designers I have talked to in the past considered the amount of light recycling gain can be overcome by “time” as the output of LEDs has kept increasing over time in a very fast pace following Haitz’s law. This law, the LED equivalent of Moore’s Law, states that the LED output increases by a factor of 20 in 10 years, which equates to 26% per year, without incurring any cost to the product at all as the cost of LED also decreases over time. It was seldom understood, or acknowledged that the recycling gain is additive and is on top of the Haitz’s law gains regardless of the LED output improvements or reduction in LED costs. The extra cost of light recycling that produces lower cost per screen lumen is independent from Haitz’s law.

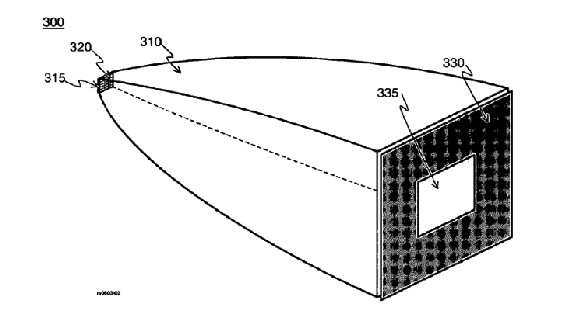

Looking at patents and some of the reported projector designs, it seems that most of the recycling techniques described are based on area recycling and most of them use light pipes or CPCs as the light recycling optical components. The light pipes are usually tapered such that the output end area is larger than the area of the LED and the output angle is smaller than that of the LED. The input ends are designed to match the area of the LED and will collect light from all angles with full etendue. The output ends of the light pipes or CPC are partially covered with mirrors or reflective coatings such that part of the output light is reflected back to the LED while the rest of the uncovered output end forms the output area, which is smaller, lowering the etendue of the system. The output area is designed such that the etendue matches with the etendue of the imager.

Since the light pipes or CPC collects all the light from the LED in both area and angle, the brightness will be the average of the brightness from all angles, which is significantly lower than the on-axis brightness. As a result, even after recycling, the output brightness may not be as bright as the on-axis output brightness of the LED without averaging.

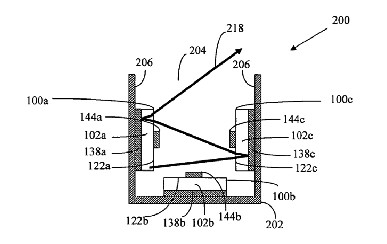

There is another system used in LED light recycling, which consists of a reflective cavity with many LEDs mounted inside this cavity. The output from each LED will be coupled to the output of the cavity directly or reflected one or more times by the cavity wall, or by the other LEDs, contributing to an increase in brightness of the system. Again, the maximum on-axis brightness of the LED is not exploited.

On the other hand, I have not seen a lot of angular recycling in both patents and other published information. This is the recycling method that will capture the high brightness of the on-axis brightness of the LED, and recycles the lower brightness high angle light back to the output for truly increased output brightness without any of the uncertainty in the area recycling method.

On the other hand, I have not seen a lot of angular recycling in both patents and other published information. This is the recycling method that will capture the high brightness of the on-axis brightness of the LED, and recycles the lower brightness high angle light back to the output for truly increased output brightness without any of the uncertainty in the area recycling method.

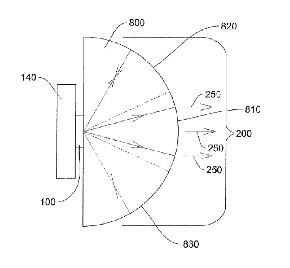

Angular light recycling optics are usually made in the form of a concave reflector, reflecting all the high angle light back to the LED with an output aperture that determines the output angle of the light recycling system. As a result, these reflectors are usually hemispherical in shape with deep cavities, and it’s difficult to apply reflective coatings. To overcome such problems, the author developed a solid plastic or glass optical system, the Light Recycling TIR Lens that can be molded into a single piece with all reflections performed by total internal reflection (TIR) without the use of any optical coatings, simplifying and lowering the cost of the system.

To capture the best of both worlds, area and angular, the author developed a light recycling method so that larger LEDs can be used.

Kenneth Li, email: [email protected].