Okay, I know. CES is four months away, and don’t I have more urgent things to think about? Well, I suppose so, but I haven’t been to a live conference since CES 2020 and I’m itching to look at some real live advanced displays.

The first thing I want to see is a Samsung QD-OLED TV — the kind that uses unpatterned blue OLED emitters and a patterned quantum-dot layer to convert some of the blue to red and green. If you’re cynical, you might say that the primary reason Samsung adopted this counter-intuitive technology was to avoid LG Display’s Kodak patents on color-by-white OLED (WOLED). But there is a reason why QD-OLED’s front-of-screen performance could be noticeably better that WOLED’s.

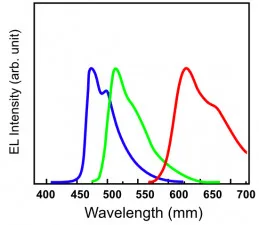

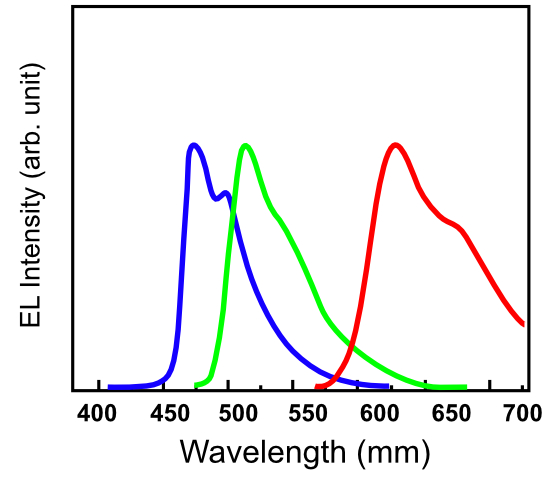

Fig. 1. The emission spectra of blue, green, and red OLED emitters are broad, which compromises color purity and the breadth of color gamut. (Graphic: source Sharp – redrawn by Meko)

Fig. 1. The emission spectra of blue, green, and red OLED emitters are broad, which compromises color purity and the breadth of color gamut. (Graphic: source Sharp – redrawn by Meko)

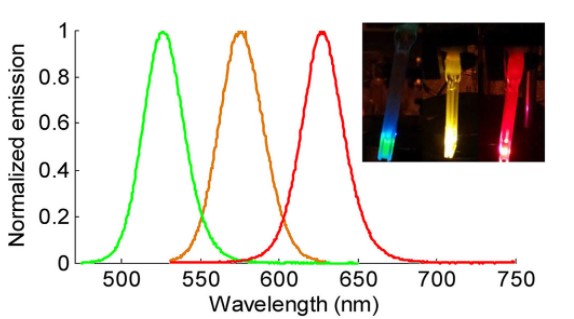

Fig. 2. The spectra from quantum dots is narrow than that from OLEDs, so the color purity and color gamut of QD-OLED TV sets should be better than that of LG WOLED sets. But how noticeable will the difference be? (Graphic: S-T Wu)

Fig. 2. The spectra from quantum dots is narrow than that from OLEDs, so the color purity and color gamut of QD-OLED TV sets should be better than that of LG WOLED sets. But how noticeable will the difference be? (Graphic: S-T Wu)

When the emission spectra of the red, green, and blue primaries in a display have narrower emission spectra, the color purity is greater and the color gamut is expanded. Now, the spectra of OLED emitters are broad (Fig. 1), while the the spectra of quantum dots are narrow (Fig. 2). So, the red and green spectra in a QD-OLED display should be significantly narrower than those in a WOLED display. How noticeable and/or measureable will the difference be? That’s what I want to see.

I also want to talk to the companies that are developing very small µLEDs for µLED displays. (They would also be useful in miniLED-style backlights, although I guess that would make them “µLED backlights”). You need a lot of µLEDs for a TV display (4000 x 2000 is 8 million pixels, and you need three subpixels for each pixel. That makes 24 million µLEDs.)

Since the semiconductor substrates for LEDs are expensive, the only way you can make a screen affordable is by making the µLEDs very small — on the order of one to five microns. This is difficult. Among the problems is that small LEDs are less efficient than larger ones because the edges that are damaged in the die separation process have more and more effect on the die as it gets smaller. But companies are working on materials and processes for passivating the edges and improving efficiency.

That still doesn’t solve the “mass-transfer” problem: removing all of those dice from their wafers and depositing them in their specified positions on the display substrate quickly enough with sufficient yield to make an affordable display. I look forward to continuing the face-to-face discussions I had pre-Covid.

Please note the Consumer Technology Association is requiring proof of vaccination to attend CES 2022. I’m getting my third shot in October. (KW)

Ken Werner is Principal of Nutmeg Consultants. He consults for attorneys, investment analysts, and companies re-positioning themselves within the display industry or using displays in their products. He is the 2017 recipient of the Society for Information Display’s Lewis and Beatrice Winner Award. You can reach him at [email protected].