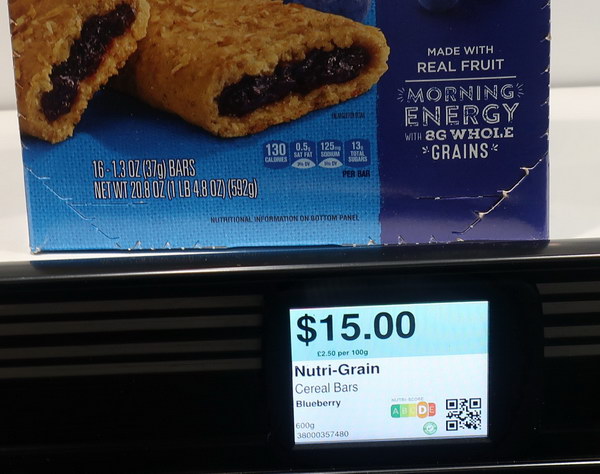

I went to the National Retail Federation’s (NRF) Big Show recently and one thing I looked at in detail was electronic shelf-edge labels (ESLs). Calling them either ‘shelf-edge’ or ‘labels’ minimizes the technology since some of the displays are 12” or more and others will show full-motion video but, still ESL is the generic name used by everybody.

ESLs range in size from about 1.5” diagonal on up. About 2.5” diagonal is the largest that can actually be used on the shelf edge but larger sizes are often used on the shelves themselves, sitting next to the product and giving more product information than just price.

Three color, e-paper-based tags in the Displaydata booth at NRF show additional information on products beyond just the price. (Credit: M. Brennesholtz)

ESLs are a big business and a significant part of the display market. According to 360 Market Updates, the business will grow at a CAGR of 21% and become a $1.24 billion business by 2023. (Global Market Insights forecasts $1.1B by 2024) It is an especially important business for E Ink, as discussed in Steve Sechrist’s Display Daily, because they supply most of the e-paper material used in ESLs. Most ESLs are battery powered and E Ink e-paper materials consume no power except when they are updated.

Typically, the update is via a wireless technology, either using RF or Infra-Red (IR) communication protocols. These protocols are almost always proprietary to the ESL manufacturer. For example, if you have an installation of Pricer ESLs and want to expand your store, you would normally need to buy more Pricer ESLs, you can’t easily switch to their biggest competitor, SES Imagotag or one of the smaller companies in the business.

If you really wanted to switch, you would have two choices, neither of which has much appeal. First, you could replace all the existing tags in your store with the other brand, not simple or cheap because a large store can have 30,000 tags or more. Alternatively, you could install a second, parallel communication system in your store and then deal with the fact that not only the communication technology for the new brand is incompatible but the update software on your server is incompatible as well.

Graphical E Ink tags aren’t the only game in town, although they dominated the ESLs on display at the NRF. Other approaches include:

- E Ink material on a 7-segment backplane

- Reflective LCD on a 7-segment backplane

- Full color LCDs with backlights

- Emissive LED displays

LCD ESLs from Lenovo at NRF, including a shelf-top display. (Credit: M. Brennesholtz)

LCD ESLs from Lenovo at NRF, including a shelf-top display. (Credit: M. Brennesholtz)

These last two technologies consume too much power to be battery powered and would normally be mounted on shelf edge rails that supply both power and data to the labels. Both LCD and LED technologies can show full motion, full color video and normally would be used when the retailer wanted to have ESLs show promotional material, not just prices. These ESLs would commonly be combined with a larger shelf-top display, as shown in the image, to expand upon the message and provide additional information.

Small, full color LCD ESL from SFD. The power and data traces are visible on the rail behind the ESL. (Credit: M. Brennesholtz)

Small, full color LCD ESL from SFD. The power and data traces are visible on the rail behind the ESL. (Credit: M. Brennesholtz)

While emissive LED ESLs were only shown at NRF by one startup company (AWM Smart Shelf) and the ones shown had poor resolution, perhaps with the declining prices of microLED and miniLED displays, they will become a commercial factor in the future.

On the other hand, LCD ESLs were shown by multiple companies, including Lenovo, SES Imagotag, SFD Systems and Opticon. In the past, sometimes these long, narrow LCDs were produced by cutting down larger panels. This is no longer necessary and companies such as Innolux and AUO make these sized panels directly on the mother glass at the fab.

People at NRF described them to me as “4K,” although clearly a 12” or 24” wide display only 2” high does not have a 4K pixel count. What the representatives at NRF meant was the displays had about the same pixel pitch as a 55” UHD (4K) TV panel. For example, the 48” wide shelf top display in the Lenovo photo has 3840 x 720 resolution. The smaller LCD ESLs actually intended for shelf-edge use are more commonly 24” or 12” wide so two or four units are needed to fill a 48” wide shelf in the US. Since ESLs are designed to be viewed from up close, this fine pitch resolution is actually needed by the displays.

AUO made displays, including LCD ESLs, in the ComQi booth at NRF. (Credit: M. Brennesholtz)

AUO made displays, including LCD ESLs, in the ComQi booth at NRF. (Credit: M. Brennesholtz)

While AUO wasn’t at NRF, its wholly owned subsidiary, ComQi Inc. was there. While ComQi is a software development company for the retail industry, their booth featured AUO-made displays, including ESLs. Like the representatives of most companies at NRF, the ComQi representatives knew few technical details about the displays they were showing.

The main reason retailers are shifting from printed shelf edge labels to electronic ones is to reduce the labor cost of updating the pricing of items in the store. Rather than have an employee go from item to item to update tags, a process that can take days or even weeks, if every item in the store needs an update, the update can be done remotely. The update speed depends on the resolution of the display and the details of the communication protocol. For larger (e.g. 12.2”), graphical displays, the update speed can actually be quite slow, with 150 displays per hour under US FCC rules or 300 per hour under European CE rules. Smaller, graphical tags can be updated much faster, typically at 7500 per hour. 7-segment tags typically require very little data so update rates can be as fast at 30,000 per hour, depending on the communication protocol.

7-Segment LCD ESL from Prices can only show Price, not product name, which must be applied manually. (Credit: M. Brennesholtz)

7-Segment LCD ESL from Prices can only show Price, not product name, which must be applied manually. (Credit: M. Brennesholtz)

The fact that 7-segment tags need little data and can be updated very quickly is actually a mixed blessing. The 7-segment tag cannot show the product name, only its price. If the location of a product on a shelf is changed, either the tag associated with the product needs to be moved as well or a new paper label applied to the tag.

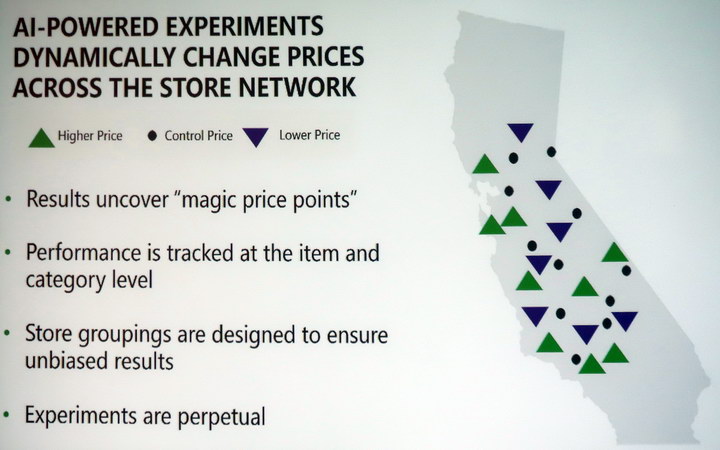

Eversight uses ESLs and AI-based software to determine optimum price points for a product. (Credit: Eversight)

Eversight uses ESLs and AI-based software to determine optimum price points for a product. (Credit: Eversight)

While fast and easy updates of product prices is the main reason for ESLs and product promotion at the shelf is the secondary reason, I talked to two people who had unusual applications that were enabled by ESLs.

First, I attended a seminar presented by David Moran, Chairman and Co-Founder of Eversight, who discussed his company’s AI-based technology for finding the optimum price for a product in a retail store. Finding the optimum price involves finding the price elasticity of a product. When you raise a price, how much do sales decrease and when you lower a price, how much do sales increase?

Retail stores currently have ways of determining this elasticity that don’t involve ESLs or AI, but they are labor intensive, produce only a few data points and are prone to error. If you have ESLs in a chain store with multiple locations, you can raise the price in some stores, leave it the same in others and lower it in the rest. This can produce a vast amount of data which includes every individual sale of the item in every store and at what price along with the sales and prices of competitive products.

Massaging this large data set with AI and “Big Data” techniques allows the price elasticity to be determined very accurately and the optimum price to be set. This price will not be the lowest price because while that has the maximum sales volume, there is little or no profit per sale on each item. The optimum price is also not the highest price which may produce the most profit per item but relatively few sales are made. This low sales volume may also drive up the price charged by the supplier, reducing or eliminating the added profit per item.

I talked to Moran later in the Eversight booth. He said the company’s pricing technique does not absolutely require ESLs and can be done with conventional printed shelf edge labels. However, with ESLs, it is easier to control the process from a central point (i.e. corporate or regional headquarters) without requiring the stores to put the effort into changing labels. It also allows the experiment to be perpetual, which will uncover changes in elasticity and the optimum price based on outside factors such as a change in the competitor product.

Wasteless technology and ESLs allow products to be automatically marked down as the approach their expiration dates. (Credit: Wasteless)

Wasteless technology and ESLs allow products to be automatically marked down as the approach their expiration dates. (Credit: Wasteless)

Another application of ESLs that cannot be done with printed labels was demonstrated by Wasteless. Wasteless did not have a booth of their own at NRF but I talked to their representative in the Pricer booth. Their basic idea is to adjust the price of a product based on its expiration date, reducing the price as the expiration date came closer.

The idea behind this is once the product reaches its expiration or sell-by date, it must be thrown away and is a total loss for the retailer. By selling it at a reduced price, at least the store gets some income from the product. One requirement for this is the product must be marked by a consumer-readable expiration, use by or sell by date. On some products, this data is encoded and not consumer readable or is in fine print and not easily found. Items like dairy products, however, commonly have clearly marked dates.

14” E Ink full-color e-paper display in the Pricer booth at NRF. (Credit: M. Brennesholtz)While E Ink is a major supplier of material to the ESL industry, they were not an exhibitor at the NRF. They were showing their full color e-paper technology in the Pricer and SES Imagotag booths. In the Pricer booth, they had a 14” unit, shown above. In the SES Imagotag booth was a much larger 32” unit. The representatives at both Pricer and SES Imagotag said they had no immediate plans to release a ESL product based on the full color E Ink material. Among other problems, the material required too much power to update and realistically could not be used in a battery-powered application. Once you have external power, an LCD display with better color, higher contrast and full motion capabilities makes more sense. –Matthew Brennesholtz

14” E Ink full-color e-paper display in the Pricer booth at NRF. (Credit: M. Brennesholtz)While E Ink is a major supplier of material to the ESL industry, they were not an exhibitor at the NRF. They were showing their full color e-paper technology in the Pricer and SES Imagotag booths. In the Pricer booth, they had a 14” unit, shown above. In the SES Imagotag booth was a much larger 32” unit. The representatives at both Pricer and SES Imagotag said they had no immediate plans to release a ESL product based on the full color E Ink material. Among other problems, the material required too much power to update and realistically could not be used in a battery-powered application. Once you have external power, an LCD display with better color, higher contrast and full motion capabilities makes more sense. –Matthew Brennesholtz