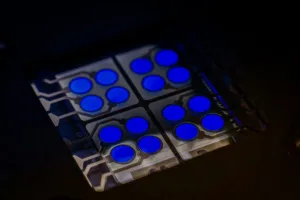

Last week Cynora, the German developer of thermally activated delayed fluorescence (TADF) OLED emitters, announced its first commercial product, “a fluorescent blue emitter that promises to significantly improve the efficiency of Organic Light Emitting Diode (OLED) displays.” The product, which Cynora calls cyBlueBooster™, is more than 15 percent more efficient than comparable emitters, the company says. CyBB “can be easily integrated into existing OLED stacks and is available in multiple shades of blue for application customization.”

Cynora’s cyBlueBooster is a fluorescent blue OLED emitter that is more than 15% more efficient than conventional fluorescent blue OLEDs. (Photo: Dr. Harald Flügge)

The company’s press release does not make it clear whether cyBB is a TADF, so I asked and Cynora’s U.S. media representative Jane Evans-Ryan answered:

“The product is not TADF-based. However, it has its origin in Cynora’s TADF-Blue R&D. In the course of its research, the team discovered a material class that works very well as a fluorescent emitter. Made sense to commercialize, given a) the intrinsic efficiency advantage for customers, and b) the opportunity to start generating revenue. “

Cynora says the new product is the first on a technology roadmap that will later include green and blue TADF-based emitters. In addition to its increased efficiency, cyBB has a better color point. The narrow emission spectrum of less than 30nm full width at half maximum reduces the production of ultraviolet light. CyBB can be seamlessly integrated into existing OLED devices with only minor adjustments to the stack, Cynora says. “Customers can select a shade of blue to optimize their stack and further differentiate their OLED products.” Cynora CEO Adam Kablanian, said the product was built in collaboration with OLED ecosystem partners with simplicity of integration in mind.

“We’re pleased to mark this first commercial milestone.”

The blue OLED emitter is the least efficient of the three primaries and has thus far defied attempts to improve it for commercial applications, so cyBB’s 15 percent is a significant development.

In a less happy piece of OLED news, inkjet printing (IJP) developer Kateeva recently announced it will reduce its staff by 144 people, including its president, CMO, and COO. This is a fall from on high as Kateeva was a leader in OLED IJP, and was working with Samsung, BOE, and LG, among others, according to Andrew Abrams of Supply Chain Market Research. Kateeva was planning to supply Samsung with the IJP equipment to pattern the quantum dots for Samsung’s QD-OLED TV line. But, according to Abrams, Samsung decided on tools from Korea-based SEMES, and the blood bath inevitable ensued.

Abrams says Kateeva expects a new investment from Chinese companies, and Kateeva will shift its focus to support the Chinese in their efforts to use IJP for OLED encapsulation. Kateeva will no longer be working on printing of OLED materials. (KW)

Ken Werner is Principal of Nutmeg Consultants, specializing in the display industry, manufacturing, technology, and applications, including mobile devices, automotive, and television. He consults for attorneys, investment analysts, and companies re-positioning themselves within the display industry or using displays in their products. He is the 2017 recipient of the Society for Information Display’s Lewis and Beatrice Winner Award. You can reach him at [email protected] or www.nutmegconsultants.com.