A consortium German companies has established the KODOS project. The acronym stands for “Konfektionierter Dünnglas-Verbund für optoelektronische Systeme” or “Thin Glass Composites for Optoelectronic Systems.” The aim of the consortium is to be able to “offer a complete modular system of functional materials, semi-finished products, tools, and technologies for the roll-to-roll production of optoelectronic systems on thin glass.”

The initial 4.5 million Euro funding for the consortium was provided by the German Federal Ministry of Education and Research within the framework of an initiative called “Photonik nach Maß.”

The consortium is led by Thomas Emde of EMDE development of light GmbH (Frankfurt, Germany). EMDE along with Volkswagen and Deutsche Werkstätten Hellerau will focus on application development. Other members of the consortium include technology suppliers’ tesa SE, VON ARDENNE, Flabeg, 4JET microtech, SURAGUS, and the Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP.

Part of the rationale for the consortium derives from the desire to capitalize on the favorable properties available from thin glass such as flexibility, a very smooth surface and scratch resistance. Based on these properties, thin glass is suitable for uses that include functional surfaces and/or substrates in optical devices. One such application of interest to readers of Display Daily is in OLED technology in which the thin glass can be used as the display substrate or as part of the touch screen.

The current state of the art, however, is such that several technological advances are needed before thin glass can be successfully used in high volume manufacturing. More specifically, advances are needed in technologies related to coating, structuring, contacting and lamination. In addition, will be necessary to develop a production-ready means to transition from the processed roll to the ready-to-install semi-finished product.

Discussed below are brief descriptions of the activities of consortium members in addressing these technology issues as they relate to OLED applications. The descriptions are paraphrased from a recent KODOS press release.

Concerning the lamination of basic elements, tesa will investigate encapsulating adhesive tapes for thin glass-based organic electronic devices. More specifically, the company will investigate full-surface and partial direct coatings of thin glass foils with functional layers such as hole-injection layers for OLEDs.

Flabeg will develop the process steps necessary to be able to use 3D-formed thin glass laminates for use in touch screen applications. More specifically, Flabeg will investigate a hot molding process and the lamination of uniaxially and biaxially bent thin glass.

The ability to economically implement a roll-to-roll manufacturing process that utilizes thin glass is greatly enhanced if it is possible to use a physical vapor deposition coating system as one of the process steps. The aims of VON ARDENNE in the project relate to making this a reality by ensuring stable, continuous process control with a high material yield and to develop quality parameters for evaluating the usability of the supplied thin glass rolls. In addition, VON ARDENNE will optimize the coating processes for suitability with subsequent processing steps.

Fraunhofer FEP will develop efficient coating technologies for electrodes and OLEDs. It is anticipated that new “structuring tiers” will be introduced into the roll-to-roll production process.

SURAGUS will work on the integration of processes for the characterization of key electrical and optical properties. More specifically, SURAGUS will develop the measurement technology for the characterization of the entire laminated OLED.

The next process step that needs to be addressed is the separation of finished devices from the roll. A reliable technology does not currently exist for this process step. Therefore and in particular, it is necessary to develop a high yield separation technology that produces OLEDs having high edge strength and service life.

One solution to the separation issue is the use of laser separation. This technology will be investigated by 4JET microtech. In principle, laser-cut glass edges can have the strength to meet the requirements of OLEDs. Most significantly, with laser cutting, it is possible to produce just about any cutting contour and thus any OLED shape. Also relating to OLEDs are the specific challenges of cutting glass-polymer laminates. These and other challenges will be investigated during the course of this project with the goal of developing effective manufacturing technologies.

The Deutsche Werkstätten Hellerau will investigate the sealing of wooden surfaces with thin glass and the integration of additional functions such as OLEDs into furniture.

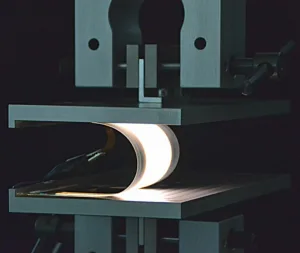

An illustration of a thin glass-based OLED under bending test at Fraunhofer FEP is presented in the figure below.

Bending test on a flexible OLED made of thin glass. Photo from Fraunhofer FEP.

A recent KODOS press release nicely sums up the goals of the consortium as they relate to roll-to-roll processing of thin glass with the statement that “Within the next three years, the project consortium will work on the development of technologies that are practical and suitable for industrial use.” -Arthur Berman

EMDE development of light GmbH, Thomas Emde, [email protected]