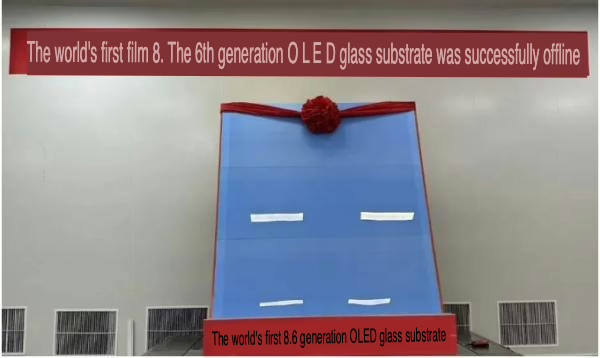

A Chinese joint venture between CNBM (Chengdu) Optoelectronic Materials and its subsidiary Bengbu Zhongguangdian Technology has produced China’s first Gen8.6 OLED glass substrate at their facility in Bengbu, Anhui Province according to reports in the Chinese press. This development is a strategic positioning of China’s entry into OLED glass substrate manufacturing.

The production of Gen8.6 OLED glass substrates must meet stringent specifications: ultra-smooth surface quality with roughness typically below 1nm, exceptional thermal stability to withstand high-temperature OLED processing (up to 600°C), and precise thickness uniformity (typically ±5μm) across large areas. The Gen8.6 size (approximately 2290mm x 2620mm) presents particular challenges in maintaining these properties at scale.

The substrate’s composition requires careful engineering of glass network formers (primarily silica) and modifiers to achieve the necessary coefficient of thermal expansion (CTE) matching with OLED materials. Additionally, the glass must maintain high optical transmission (>90% in visible spectrum) while being thin enough (0.5mm or less) to enable flexible display applications.

The float glass manufacturing process for these substrates demands precise control of molten glass chemistry, temperature gradients, and cooling rates to prevent devitrification and ensure uniform properties. Any microscopic defects can lead to device failure, making the achievement of consistent quality at Gen8.6 scale particularly significant for display manufacturing yields. Major display manufacturers including Samsung, BOE, and Visionox are currently developing Gen8.6 OLED panel production lines. The research was supported by China’s national research program focusing on OLED display glass material technology development.