It’s been some time since we have heard about RoHS and cadmium-containing quantum dots (QDs), but trust me, it’s still an important topic for many companies in the display industry.

To set the stage we must first understand a little bit of history about Restriction of Hazardous Substances (RoHS) and European Commission, as well as other players involved.

RoHS began in 2006 as a way to limit the amount of hazardous chemicals in consumer electronics. Think lead solder in electronics, mercury in thermostats, etc. There are standard limits for a handful of elements and compounds. For example lead and mercury are set at 1000 ppm while cadmium is set at 100 ppm. In special cases there can be exemptions for higher limits, but of course this requires a strong argument for why a higher limit is necessary. When these requests come about, the European Commission subcontracts the evaluation and recommendations to other parties. In the case of exemption 39 (cadmium in LEDs and displays) Oeko Institute in Germany was called upon to evaluate and provide a recommendation. For exemption requests, typically an evaluation is performed along with input from stakeholders that would be impacted by the exemption. Following the evaluation, a report/white paper with formal recommendation is published and provided to the European Commission who then votes on it (I’m simplifying of course). If it passes, it becomes law. It is not guaranteed that the Commission will accept the recommendation from outside evaluators like Oeko. While technically speaking the RoHS directives only apply to EU member states, many other parts of the world follow close behind. Companies who want to sell products in Europe would rather not revamp their product for Europe alone, so generally they try to meet the most restrictive guidelines worldwide.

Exemption 39 (cadmium in displays) was first considered in 2008, at which point 3M was a major play developing QD films. At that point in time, CdSe-based QDs were far more mature than any other QD type in terms of efficiency, color purity, and reliability. They had been well-studied, and scientists understood how to make them in high yield, purity, and with excellent performance. Displays containing these QDs provided enhanced performance and efficiency, so, it made a lot of sense for the European Commission to grant an exemption. In 2011 they granted an exemption allowing “10 micrograms Cd per square millimeter of light emitting area” which corelates to 10 grams per square meter. While the units are different, this is far above the standard limit of 100 ppm in any homogeneous part. In 2017 the exemption was modified down to 0.2 grams per square meter. For reference, a 65 inch TV is roughly 1 square meter.

Surprisingly, this is still where we sit today. After much back and forth in the past 7 years (too much drama to include here), the exemption put in place in 2011, and modified in 2017, remains in place today. But it looks as though this could change.

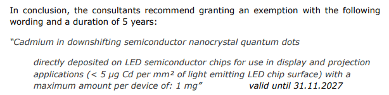

In 2022 the Oeko Institute updated their assessment on the topic of cadmium in displays and published their recommendations based on input from stakeholders and their own analysis. Their recommendation was as follows:

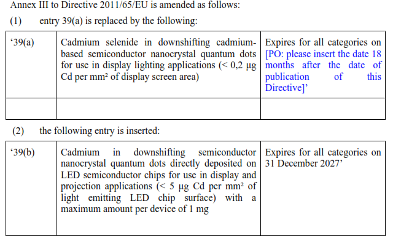

Notice the change in language. It specifies “directly deposited on LED” which would exclude all types of QD implementations in displays to date. In late 2023 there was an open feedback opportunity about the current recommendation. The implication being that the recommendation from Oeko would soon be voted on. As part of the feedback opportunity the European Commission asked for feedback on the following changes to the existing exemption:

In essence, if it passes through into law, the exemption for cadmium in displays of 0.2 grams per square meter would enter a grace period of 18 months, after which the standard 100 ppm rule would apply. In addition, a newly worded 39(b) exemption would be created in which 5 micrograms of cadmium per square mm of LED chip would be allowed. Interestingly they put a cap on each device (in case of a larger chip size I guess) of 1 milligram. The wording proposed by Oeko in 2022 was carried through in the European Commission feedback request, and it is likely that this wording is what will ultimately be voted on.

So what is the impact on QD technology in displays? I have separated my thoughts into two categories, impact on current technology and future technology.

Impact on current technology

QD films (QDEF) will see minimal impact since most companies have already transitioned to <100 ppm cadmium already. Either by optimizing the amount of cadmium in their CdSe QDs, or by substituting with InP QDs. In many cases the films contain 0 ppm cadmium. The same is true for extruded QD diffusers (x-QDEF) where, in theory, CdSe or InP could be used. If some companies are using over 100 ppm cadmium, they will have at least a full year to re-design to meet the new requirements.

QD-OLED, which uses far higher QD concentrations, already uses only InP QDs, so I expect no impact there either.

Where there could be a big impact is on QDs used on-chip. The wording of “directly deposited on the LED” implies this exact technology. Here the 39(b) rule would come into play, allowing for a much higher concentration of cadmium compared to what is currently in use. To my knowledge, only OSRAM has LEDs with Cd-QD containing QDs on-chip, but they are not currently used in displays. However, with a higher limit on cadmium, OSRAM or others could conceivably start to compete with blue LED + QD films by offering a blue LED with green + red Cd-containing QDs to generate QD-quality R/G/B spectrum from a single LED chip. It will be interesting to watch how this plays out.

Impact on future technology

Here I see a potential for impact on microLED with color conversion. With a higher limit on cadmium content, one might think it is a good sign for those developing microLED-based systems. My concern lies in the size of the microLED. Since they are only, say 10×10 microns (.0001 square milimeters) then the amount of cadmium that can be used would be vanishingly small. In this example only 0.5 nanograms (ng = 10^-9 g) of cadmium would be allowed for each chip. Probably this is even difficult to measure with any accuracy. I expect most companies developing Cd-containing QDs for microLED will attempt to remain under the standard 100 ppm limit which means the exemption is a moot point.

Electroluminescent QLED could, in theory, also be impacted by the removal of the prior exemption. Since these devices use only a very thin layer of QDs (1-3 monolayers) they tend to have only small amounts of cadmium. It is possible, depending on how one defines a homogeneous part, that they remain <100 ppm cadmium as many have argued. I’ll let the lawyers and politicians figure that one out. Since this technology is not yet commercial, we could see exemption requests as resurface for EL-QLED if it is determined that an exemption is required and appropriate.

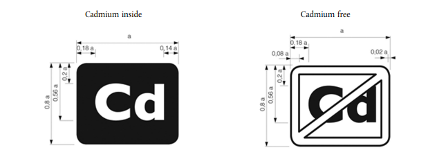

Finally, a fun fact based on language that was added in the 2019 eco-design requirements. All electronic screens that contain more than 100 ppm cadmium must now carry the black “cadmium inside” logo, while all screens that contain less than 100 ppm must carry the white “cadmium free” logo.

You are reading that right. If a screen contains 99 ppm cadmium, it will be called “cadmium free.” Not confusing to consumers at all, right?

It has been 13 years since the original cadmium exemption was put into place. Not many people in the display industry would have predicted that it would last this long, but here we are. It appears as though the exemption will not go away, but will, once again, be modified. This time with QDs on-chip becoming the focal point of the exemption. I’ll keep you updated as things progress.

Peter Palomaki is the owner and chief scientist at Palomaki Consulting. He is widely recognized for his display teardown videos and scientific approach to helping clients. He utilizes his expertise in quantum dots and materials chemistry to solve challenging problems with clients large and small.