In case you missed it, a new 3D printing system, just recently commercialized, is using TFT LCD technology as a photo mask with an array of UV LEDs as a planar light source, to manage solidification area by controlling TFT-LCD photomask. It’s called light induced planar solidification, (LIPS) and the technology is helping move us from a world of 2D display images into 3D solid form (photons to waves?).

Here AMLCD’s are used to create light induced planar solidification (LIPS) in place of DLP and laser light based approach. It is similar to stereolithography (SLA) technology but has overcome the speed and build size limitations according to the group. The LIPS technology allows a very high level of detail, and the YouTube video featured Notre Dame cathedral as one example of what may be produced. Team Owl Works using technology licensed from Korea based Ryujin Labs, Inc. said it is also compatible with a variety of generic resins based on the applications.

Commercialized Morpheus MK4 LIPS based 3D Printer uses AMLCD technology and LED light source

The newly commercialized resin 3D printer, called Morpheus MK4 (and four other versions) is a patented resin 3D printer. The work is a direct offshoot of technology first shown in 2015 at the SID iZone prototype exhibition that has become a regular part of DisplayWeek. Benefits of LIPS include a much finer resolution over large volume, scalability of build volume, high productivity and low cost according to the material presented to SID.

In case you were wondering if 3D printing has moved from hobby to full blown commercial industry, Marianne D’Aquila, research manager, Customer Insights & Analysis at IDC recently said

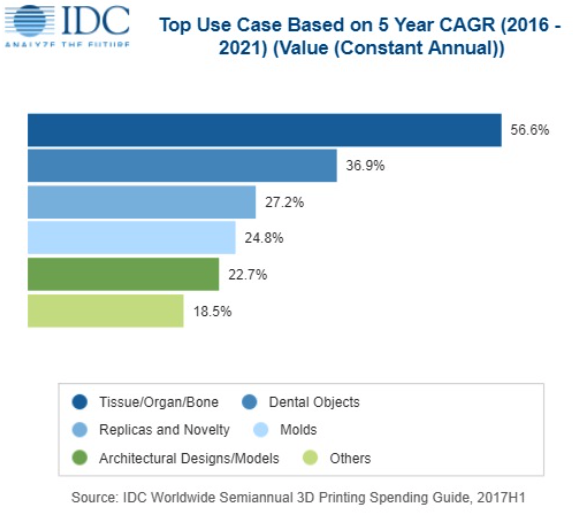

“3D printing solutions have moved well beyond prototyping, to become prevalent within and across multiple industries,”in the International Data Corp (IDC) update on 3D Printing. “Parts for new products, aftermarket parts, dental objects, and medical support objects will continue to see significant growth opportunities over the next five years as 3D printing goes more mainstream. The healthcare industry is also poised to double its share of spend through 2021 as the benefits of cost-effective customized printing continue to be realized.”

IDC reckons that there will be almost $12 billion of global spending this year on hardware, materials, software, and services in the space. IDC said that the number represents an increase of just under 20% over 2017, and the 3D space looks to hit $20 billion by 2021 with a five year CAGR of 20.5%. Those are healthy numbers for any new technology.

The Framingham, MA based market research company also said that 3D printers and materials should account for 66% of the worldwide spending total throughout the forecast period and should hit $6.9 billion in hardware and $6.7 billion in 3D printing materials by 2021, with services spending at $5.5 billion. That number will be led by on-demand parts and system integration services, with 3D printing software trailing growth in the space.

With the promise of overcoming the speed and build size limits of 3D stereolithography printing, AMLCDs have found new applications in the booming 3D printing industry, empowering the patented LISP light induced planar solidification, method. And isn’t it interesting that the first displays used in computers, years back were — you guessed it, line printers… moving us full circle in our continual reach toward technology nirvana? — Stephen Sechrist