A research team headed by Professors Song Myung-hun and Kim Joo-young of the Materials Science and Engineering Department at the Ulsan National Institute of Science and Technology (Ulsan, Republic of Korea) recently announced developments related to flexible Perovskite Light Emitting Diodes (PeLEDs).

First a few words of background information. A PeLED is a type of LED that produces light by injecting current into an active layer that is composed of a perovskite material. (An easily readable description and informative article of perovskite materials can be found here in Wikipedia.) Advantages of perovskite-based LEDs include high electron mobility, good color purity and a simple means to control the color of the emitted light. There are, however, also disadvantages with conventional PeLEDs. Two of these disadvantages are low physical flexibility and the fact that devices that include the material are opaque. The opacity is due in part to the use of metal electrodes.

Recent research by the team was intended to address these issues. The latest results on this topic by the team are contained in an article entitled “Flexibility of Semitransparent Perovskite Light Emitting Diodes Investigated by Tensile Properties of the Perovskite Layer.” The article was published on-line on January 15 in Nano Letters and can be found here.

In this study, one goal of the team was to produce transparent and flexible electrodes. To accomplish this, a mixture of two ionomers of the polymer polystyrene sulfonate (PEDOT:PSS) was used in the anode and silver nanowires were used in the cathode. In addition, the team used a conjugated polyelectrolyte as an interfacial layer to reduce the electron injection barrier between the cathode and the electron transport layer. This polymer electrolyte helps electrons move more easily and, thus, enhance device efficiency.

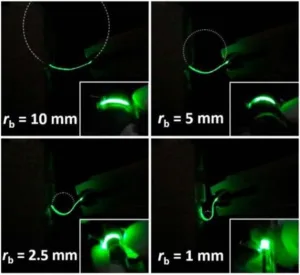

The transparency of a device based on the PeLEDs increased to 50 percent, much higher than in a conventional device. This PeLED device was described by the team as being translucent. In addition, the luminescence characteristics of the PeLED device were maintained even when the device was bent into a curve with a radius of 2.5 mm.

The figure below illustrates device luminescence under a series of bending conditions.

A translucent PeLED is shown to maintain light emission performance even when bent.

The study also includes a discussion and the results of an investigation into more effective techniques to measure the mechanical properties of PeLEDs.

The team explained the need for such an investigation by reporting that the flexibility of perovskite LEDs has previously been studied utilizing methods that include the cyclic bending of the entire PeLED device followed by measurement of the efficiency of the device. Utilizing this method, the flexibility of the perovskite layer itself is not systemically investigated.

The new measurement technique, on the other hand, measures the flexibility of the device by measuring the elastic limitations of the constituent materials. This approach is reported as enabling a more accurate means to analyze the causes of degradation in the device.

As a practical matter, the mechanical properties were analyzed by “lightly grabbing or pressing the constituent materials produced by the same method as the PeLED manufacturing process.”

Cyclic bending and other tests performed on the constituent materials suggest that mechanical failure occurs in the perovskite layer. This mechanical failure, in turn, was shown to lead to a decrease in device luminance. The team reported that an analysis of the tensile properties of the layers explains why the critical bending radius of the perovskite LEDs is of the order of 1 mm.

In their article, the team goes on to explain that perovskite materials readily react with moisture or oxygen in the air. Such reactions are known to degrade device performance. In order to deal with this issue, the research team measured some mechanical properties of several constituent materials by using an electron microscope that operates in a vacuum.

Referring to the new means of measurement, the article concludes with the statement that “In addition to PeLED, the technique can also be used for multi-layered flexible devices.” -Arthur Berman

Ulsan National Institute of Science and Technology, Ju-Young Kim, [email protected], +82-52-217-2334