There’s an interesting paper out that highlights a recent development in the creation of transparent and antimicrobial surfaces for touch displays, particularly for devices like tablets and smartphones. Traditional methods of cleaning these devices, such as alcohol sprays or wipes, can be damaging to delicate displays. Therefore, there’s a growing interest in finding alternative solutions, such as antimicrobial coatings applied directly to the glass.

Researchers wanted to address the challenges of creating such coatings, particularly the need for transparency and durability. While copper is known for its antimicrobial properties, traditional copper coatings are opaque and can interfere with touch sensitivity. However, scientists at the Barcelona Institute of Science and Technology have developed a transparent nanostructured copper surface (TANCS) that overcomes these issues.

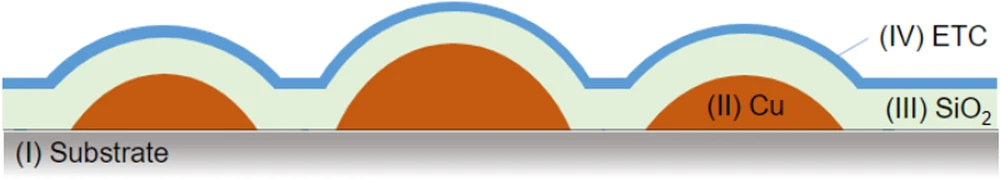

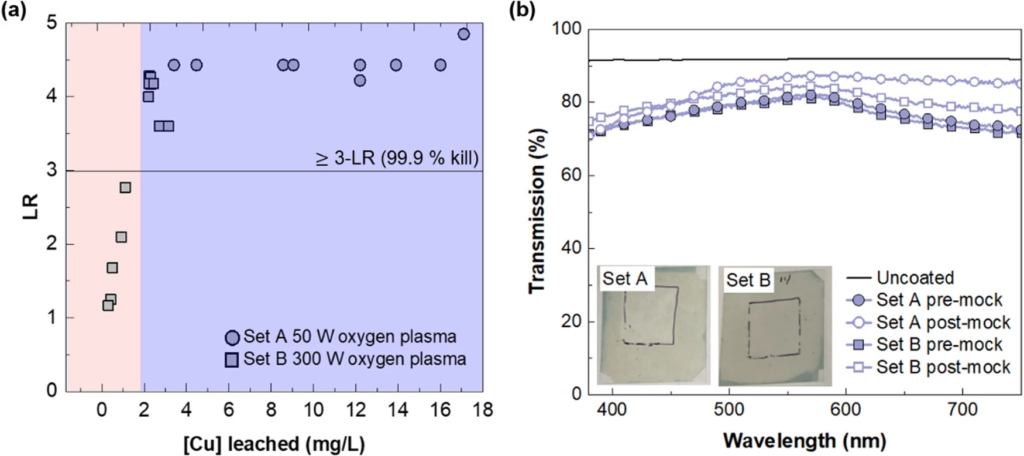

The fabrication process involves depositing an ultra-thin copper film onto a glass substrate and then using a rapid thermal annealing process to form dewetted copper nanoparticles. Additional layers are added for environmental protection and improved durability. The resulting surface exhibits antimicrobial properties, transparency, color neutrality, and electrical insulation. The TANCS demonstrated high antimicrobial efficacy, optical transparency, and durability, making it a promising solution for touch displays.

Reference

Graham, C., Mezzadrelli, A., Senaratne, W, Pal, S., Helen, D. Hepburn, L., Mazumder, P., Pruneri, V., (2024). Towards transparent and durable copper-containing antimicrobial surfaces. Communications Materials Doi: https://doi.org/10.1038/s43246-024-00472-w