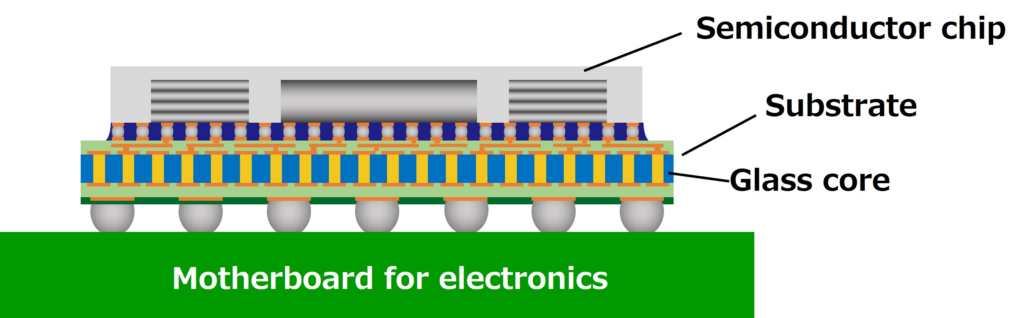

DNP’s (Dai Nippon Printing) new Glass Core Substrate (GCS) replaces conventional resin substrates, such as Flip Chip-Ball Grid Array (FC-BGA), with a glass substrate. It uses high-density Through Glass Via (TGV) technology, and the company claims that their GCS can offer better performance in semiconductor packages compared to existing solutions. Moreover, the new product can meet the demands for high efficiency and large-scale substrate production by adopting DNP’s panel manufacturing process.

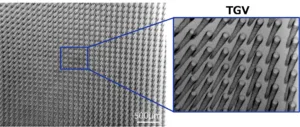

One key feature of the newly developed GCS is the fine pitch and high reliability achieved by incorporating TGVs, which are essential for connecting fine metal wiring on the front and back of the glass. DNP claims its novel manufacturing method significantly improves the adhesion between glass and metal, a feat that was difficult to accomplish with traditional methods. Another notable aspect of the new glass substrate is its high aspect ratio of over 9:1 and scaling capabilities. This allows for the configuration of fine wiring while maintaining adequate adhesive properties. Furthermore, the flexibility in glass substrate thickness enables designers to optimize warpage, rigidity, and flatness with greater freedom. In the context of display product manufacturing, GCS’s advancements in semiconductor packaging could improve the performance of integrated components within display devices.